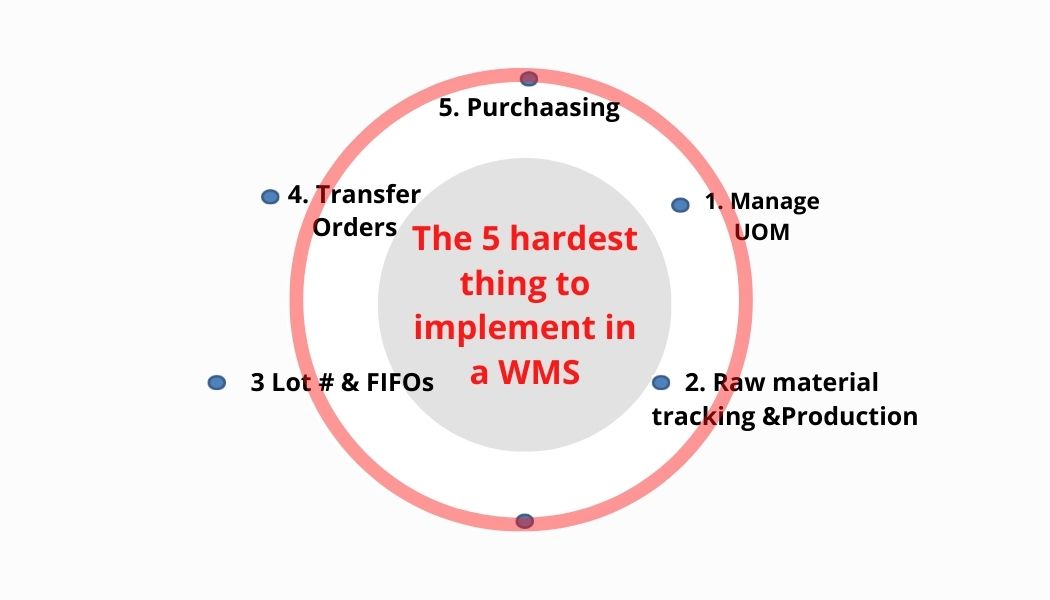

5 hardest things to do in your Warehouse Management System (WMS)

Many distributors and manufacturers want a WMS that allows them to control all inventory and production operations: purchasing, production, and inventory management at low prices. But the truth is that a warehouse management system that does all of that, not only costs you, but it is hard to find and will probably requires customization. In this article I will talk about the five things that you need to watch out for when analyzing a proposal from a WMS supplier.

Number one: Manage weighted UOM

Managing weights is one of the most difficult things to track in a Warehouse Management System. Many products have both weight and quantity associated with them and they usually have a short shelf, like meat, poultry and vegetables. The catch is that you receive the product in quantities with different weights and different expiration dates. The situation gets more complicated when you receive in one UOM (like KG) but sells them in a different UOM (Pounds).

If this is your case you need:

- To select a vendor that sales the product with a label on the case or sack, that has the weight, lot number and expiration date.

- To select a Warehouse Management System capable of telling you what cases are in inventory and what their corresponding weights are.

- Make sure your WMS is able to manage the conversion from one unit to another, and keep that dual UOM in the inventory. Many system providers overcome this by duplicating the item. Avoid this at all cost! This will most likely mess your inventory.

Number two: Raw material tracking and production

The second thing that is extremely difficult to do in a WMS is raw material tracking and production. Let me illustrate the situation with an example: suppose that you make cookies. One of the ingredients is flour, which is purchased by 50 pounds sacks. When you schedule a production batch of cookies you will need only a fraction of the 50 pounds, say 12 pounds. So, you pick up the sack, weight the 12 pounds, and take the now 38 pounds sack to the bin. This means that the weight of that raw material needs to be tracked over time until the raw material is consumed, and that is why tracking raw materials is so hard.

Once the raw material of all ingredients has been picked and the remaining raw materials have been staged back into the production area or its bin, we now have to do the production process. In the production process you put them in mixers or whatever the process is and, at the end of that production process, you have finished goods that must be stored in in one of the warehouse areas. The situation is complicated because it is normal that throughout that entire process you have productivity losses by your staff (they drop raw material on the ground or during the production process you have a drop in your yield for reasons x or y).

In short, if you find yourself in this situation your Warehouse Management System needs to have these capabilities:

- BOM management

- Track Inventory items that change quantity over time

- Record lost material

- Adjust BOM theoretical use of raw material, with the actual waste during the production process

Number three: Lot numbers and FIFO

The next thing to consider is lot numbers and FIFO. I have written about FIFO in multiple posts, but i it is important to note that this is one of the hardest things to do in your warehouse because it requires a paradigm shift in your organization in order to get it done. Many manufacturers are satisfied with just knowing what product and what lot goes into your picking bin and then out of the picking bin to an order or a transfer. The issue with having this flexible methodology is that many times you mix in a picking bin the same item with multiple lots or multiple expiration dates and this will end up with inaccurate inventory and an increase in expired products.

To ensure that you ship a matching lot to a customer, you need:

- A WMS that can track lots and expiration dates and can suggest the picking bin with the best matching quantity and shortest expiration date.

- A methodology that stores only one product, one lot number and one expiration date per bin

- Many times it is easier to pick an item from a different bin than the one suggested by the system. In order to prevent this from happening you need policies that enforce picking from the suggested bin and a system that detects when wrong pickings are made.

Number four: Transfer orders

Most distributors have multiple warehouses in the area or across the country and often those warehouses transfer products from one to another to fulfill sales orders. The issue with having this is that you need to have a system that is smart enough to know when it is time to transfer from one warehouse to another and when it is time to actually purchase product from a vendor.

Normally a WMS allows you to set a minimum and a maximum where the minimum is where your availability threshold must be reached before the system triggers replenishment. But in a multi-location environment, the minimum-maximum must consider the sum of the quantities available and committed across all locations, as well as the min-max of each location; and this is a feature that cheap warehouse management systems lack.

Number five: Purchasing

Last and perhaps the most important feature in any WMS is purchasing, since your ability to respond to demand and optimize your cash flow is directly tied to precise purchasing.

Purchasing should be a simple function in any system if it were not for the seasonal and impulsive buying by customers. Purchases of many products at Christmas or Thanksgiving are well above the rest of the year. Additionally, unexpected events might trigger impulsive buys by end users; COVID is a prime example of that. Most systems are not able to automatically cope with these variations, even if they are seasonal. If you want optimal operation, your WMS must have a multiple max-min definition based on the historical average f monthly purchases.

I hope this article has been helpful to you. I will continue to post information related to warehouse management, distribution practices and trends, and the economy in general. If you are interested in this article or want to learn more about Laceup Solutions, please subscribe to stay updated on future articles.

There is a lot of relevant information on our channel. Check out this video related to the hardest issues of a Warehouse Management System.

Sorry, the comment form is closed at this time.