Importance of Transfer orders for an organized warehouse

The transfer order is one of the most critical processes in the organization of a warehouse, especially if you have more than one area or location where you store products. In this article, I will explain what a transfer order is, the different types of transfer orders and how to control them.

What is a Transfer Order?

A transfer order is a document that is used to execute the movement of goods from one warehouse location to another or the movement of goods between one storage unit and another within the warehouse. The transfer order is produced for the purpose of managing the warehouse or processing the order. These may include, order picking, stocking, order updates, repackaging, or inventory management.

Types of transfer orders

There are two types of transfer orders: Quick TO and batch transfer orders.

Quick transfer order

It is the movement of a single product from one location to another within the same warehouse. It can be from one bin to another, from one area to another or form one level to another, but always within the same warehouse.

Batch transfer orders

When you need to move more than one product, you need to issue a “Batch Transfer Order” (BTO). If the movement is within the same warehouse, the process is equivalent to making many quick transfer orders in a single document. However, if the destination is to another location, then the process is more complex as it also involves packing, loading, delivery and receiving.

Why are transfer orders important?

Transfers are the only way for a distributor or retailer chain to optimize stock and manage various processes, such as distributed inventory, expired items, and consignment policies. Here are some examples.

- Many distributors and retailers have a central warehouse to store products. Upon receipt of requests from the stores or when the system detects reorder points in any of the satellites warehouses or stores, the warehouse staff will move the items from the central warehouse to the stores using a TO.

- There are instances where one of the stores lacks a few items, but another store is not selling those items well. With TO you can balance the inventory between stores or warehouses, minimizing excess purchases and maximizing sales.

- Some distributors have a consignment policy to promote new products. In this case, TO is used in conjunction with a consignment system to keep track of these movements.

- TOs are also used to dispose of damaged goods.

How to control transfer orders

There are many problems that might arise if you do not have a proper method of handling transfer orders. You may end up storing in the wrong location; or never record the movement in your inventory or ERP system; or registering the movement in your system but it never took place.

Depending on the size of your operation, the control system can be a fully manual system or an automated solution. It is up to you, but warehouse management software integrated with your ERP yields the least chance of error. There are also other factors that might affect the efficiency of the transfer process, such as your warehouse layout and your rack & bins identification. Below, I depict the process associated with both types of transfer orders.

Quick transfer order

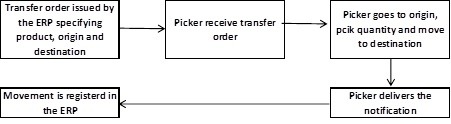

The figure below illustrates the process.

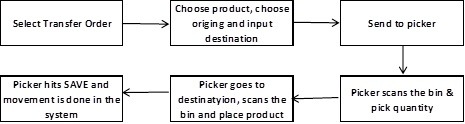

If this process is controlled by a WMS, the operation will be like this:

Batch transfer orders

BTOs behave very much like the sale order: the product is picked and placed in the picked state; it is then packed, placed in the delivery area and loaded onto a truck. But the main difference is that in the sales order the process ends when the product is loaded and deducted from the inventory; whereas in a BTO the product passes to a “shipped” or “In-Transit” status. When the truck arrives at its destination, it is unloaded and enters a receiving process where all the products that were shipped are counted and put into inventory upon receipt.

I hope this article has been helpful to you. I will continue to post information related to warehouse management, distribution practices and trends, and the economy in general. If you are interested in this article or want to learn more about Laceup Solutions, please subscribe to stay updated on future articles.

There is a lot of relevant information on our channel. Check out this video on a related subject.

Sorry, the comment form is closed at this time.