How can a distributor manage Units of Measurement

In a distribution operation it is normal for the quantity of products purchased from a supplier, stored in the warehouse and sold to customers, to have different units of measurement. In this article, I will explain what a unit of measurement is, how it works, and how to set it up within your accounting system or WMS.

Unit of measurement (UOM): Basic definitions

In a distribution and warehousing operation, a Unit Of Measurement (UOM) or unit of measure is the method by which you measure an item. UOMs are used to quantify inventory items and allow them to be tracked trough the supply chain process. It can be weight, mainly for raw material, or quantities.

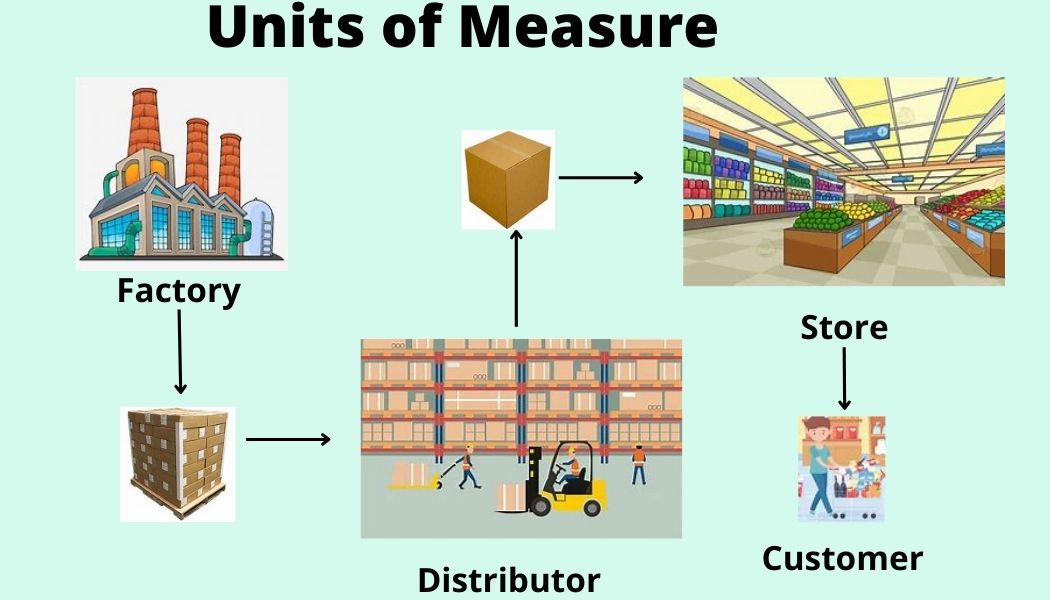

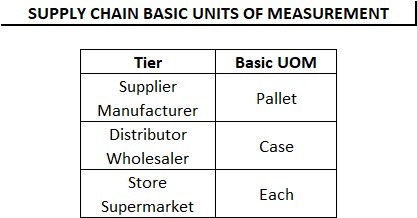

The smallest unit of a product is called the “Basic Unit”. It is normally the minimum quantity of an item that you buy in a store. For example, you can buy 1 bottle of milk or 1 cartoon of eggs, or 1 box of screws. In the wholesale industry this basic unit is called “Each”. But a distributor cannot store the products in each; products are normally packed and stored in a bigger package through which they are sold to the store or supermarket, typically called a “Case”. The “case” is nothing more than a box or bag with many “each” of the product, and it is the basic unit to sell to the stores. So, Distributor A sells to Store B 1 case of tuna cans with 10 units (each) per case. Store B receives the cases, opens them, and places the 10 cans of tuna on the shelf for the consumer to buy.

On the same token, the manufacturer does not produce or store the products in “each” or “cases”. They normally store and sell them to distributors, and sometimes directly to supermarkets, by the pallet with a certain number of cases per pallet. Therefore, the pallet is often the supplier’s or manufacturer’s base unit in the supply chain structure.

This is exactly how units of measurement work and how it works for the supplier, the distributor and the end consumer. The figure below illustrates the structure of the units of measurement along the chain.

Why are units of measurement important?

The Unit of Measure is extremely important in any context, but in inventory management and distribution transactions, it is crucial as it quantifies the inventory item in terms that all tiers of the supply chain understand and agree on. Failure to properly handle units of measure can lead to costly errors.

Let me illustrate this with an example. Store “A”’s inventory system manages the UOM as “each”, since that is its basic unit. Distributor “B”, on the other hand, uses cases as default. “A” places an order to “B” for 20 units of Tuna cans, which would be 2 cases of “B”. If “B” does not have a proper handling of units of measurement, its system might interpret that “A” wants 20 cases. This will trigger a series of actions that will cost money and customer dissatisfaction.

There are several cases of serious situations stemming from lack of coordination of the UOM inside and outside the world of commerce. I would like to stress the importance of managing the different multiples of units of measure with an incident occurred in a hospital in 1999 where a patient received 0.5 grams of phenobarbital (a sedative) instead of 0.5 grains. A grain is a unit of measure equal to about 0.065 grams. On the bright side, the patient survived,and the Institute emphasized that only the metric system should be used for prescribing drugs.

How to manage the units of measurement in your WMS?

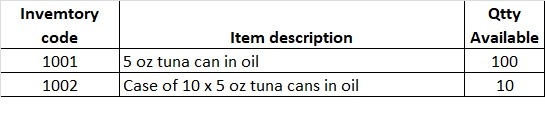

The only way to safely manage the different units of measurement is through a warehouse management system capable of handling different units of measure for the same inventory item. If your WMS does not have this feature or you don’t have a WMS, what companies do is create different codes for the same item. For example:

This poses a big problem as data entry people must manually convert and enter twice as many received items. Conversely, every time a store purchases the item, it must issue the invoice reflecting the UOM that the store is buying and manually adjust the quantities of the parallel inventory item. For example, if store “A” purchases 20 cans of 1001 (2 cases), the invoice will reflect that and the system will reduce the inventory of that item by that amount; but at the same time the operator must adjust the quantities of 1002 by 2. This makes it practically impossible to track the inventory of that item.

An ERP or WMS that has the capacity to manage different units of measurement works with your “basic unit” and has a UOM conversion table. Every time an item changes in quantity because you purchased or sold it, the system automatically adjusts the quantity of the parallel inventory code using this table and associating the change with the transaction made. In this way there is traceability of the movement for both UOMs.

I hope this article has been helpful to you. I will continue posting information related to warehouse management, distribution practices and trends, and the economy in general. If you are interested in this article or want to learn more about Laceup Solutions, please subscribe to stay updated on future articles.

There is a lot of relevant information on our channel. Check out this video related to units of measurement.

Sorry, the comment form is closed at this time.