WMS in the home service industry

Today I will talk about how a WMS should work in a home service industry environment. By a home service based business I refer to any company that does jobs that require design and manufacturing of home solutions, and inventory to execute them. It can be installing kitchen cabinets or putting in a bathroom or remodeling parts of the house. In this article I will walk you through exactly what a WMS should do and how inventory needs to be controlled within your home service business in order to keep accurate track of everything you have in your warehouse and optimize inventory and service costs.

How does the home service industry work?

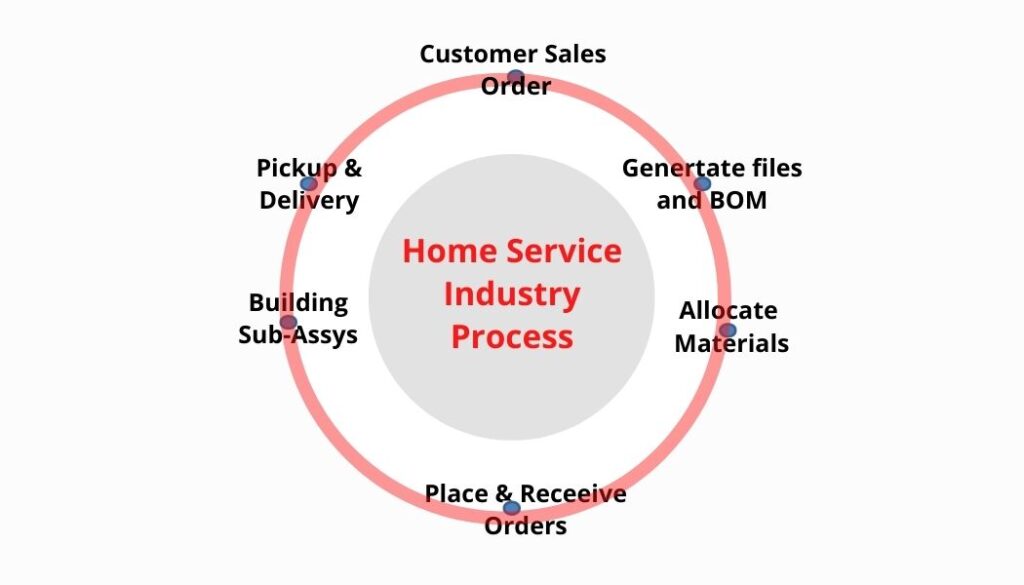

The diagram below illustrates the workflow associated with a home service industry with a brief description of each process.

Receive a custom sales order: A home product manufacturer usually has “building blocks” that are put together to meet customer needs and, sometimes, the blocks must be adapted to fit specific spaces. Every order or “job” received from a customer must be converted into plans and drawings.

Convert your “job” to files and BOM: The design associated with a sales order or job must be converted to files that will be the input to the assembly line, if applicable, and generate the “Bill of Materials (BOM)” which is a list of all the components needed to fulfil the sales order. In the wood and metal processing industry there are many software solutions that can assist you in this task.

Allocate materials: It is unlikely that all the components required for a “job” will be available in stock. Depending on the sector, between 60% and 80% of the elements of a job are on hand. These elements are “allocated” or reserved for this job and the rest must be ordered from the supplier.

Order placement and receiving: It is the process of purchasing the missing elements of an order, as well as reposition of stock items.

Building sub-assemblies: Many goods manufacturing companies need sub-assemblies to do a “job”. For instance, in the cabinet making industry you need to cut and process the wood into the panels required to assemble the cabinet. These panels, in turn, become part of the BOM for assembling the final cabinets, and can be manufactured while waiting for other components to arrive.

Picking or put away the components: When all the elements of a “job” are available they must be picked from their location in the storage and transported to the stations where the product will be manufactured or to the customer’s site for installation. This is one of the most critical processes; failure to send a component results in installation delays.

Features that a Warehouse Management System needs to have in a home service industry

Based on the way the service industry works regarding warehouse management, there are 6 features to look for when selecting a WMS that complements your operational software.

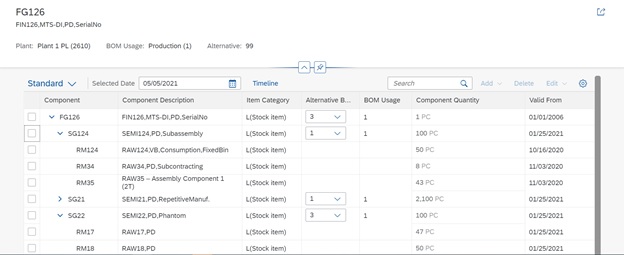

Integration with ERP or CAD software: Your WMS must be capable to integrate with the software that generates the BOM. As mentioned before, the sales order received and entered in your WMS or your ERP, must be converted into files that will be uploaded to the production machines, and will generate the BOM. This list of materials must be sent to the WMS for inventory management. At this point it is important to bear in mind that a BOM of a typical home service industry is multilevel: a job consists of assemblies (1st level), Sub-assemblies (2nd level) and accesories (3rd level) such as screws, handles, knobs, nuts, etc. Therefore, your WMS must be able to manage and allocate at all BOM levels. Below an example.

Material Allocation: Your WMS must be able to allocate or reserve available items from the BOM. Without allocation capabilities, you face the risk of not having all the items required to fill the sales order once the purchased items arrive, resulting in delays to invoice, noncompliance of delivery times, and overall operational inefficiency. However, in a home service industry, your WMS must be able to un-allocate items. This might happen when you receive an emergency job for which some items are not at hand but are allocated to another job that will be ready in a month. In this case your system should re-allocate the item to the new job and proceed to order or manufacture the sub-assembly.

Order Placing and receiving: Your WMS must be able to generate the suggested purchase order for items on a sales order that are out of stock and suggest the purchase of in-stock items based on reorder points. It must also be able to receive purchase orders with a handheld device, update the inventory based on items received and automatically allocate items ordered for the sales order they are associated with.

Job Sub-Assemble management: The construction of a subassembly is a manufacturing process; so, your WMS should have the capability to handle the production of an item based on the inventory of its components. This involves following activities:

- Allocate sub-assembly components

- Pick up the components and transfer them to the assembly area in the inventory

- Once the sub-assembly is built, transfer it to the bin where the allocated items of the sales order are.

Picking and Put Away: Your WMS must be able to detect when all the components required for a job are available, and issue a notification so that the items can be picked up. Ideally the picking is done with a handheld device so that they are deducted from the inventory and transferred to a staging zone.

Transfers: Once the components of the “job” get staged, they will inevitably be loaded onto a van or a truck. When that happens your WMS will deduct the inventory from your main warehouse and increase the inventory on your truck. That’s what we call a transfer. A transfer moves product from one location to another so at this juncture you should be able to see just how many of those products you have in your warehouse and exactly what jobs you have on a truck.

I hope this article on WMS for home service industry has been helpful to you. I will continue posting information related to warehouse management, distribution practices and trends, and the economy in general. If you are interested in this article or want to learn more about Laceup Solutions, please subscribe to stay updated on future articles.

There is a lot of relevant information on our channel. Check out this video related to home service industry.

Sorry, the comment form is closed at this time.