Picking process and warehouse productivity

The picking process is the most labor-intensive and expensive activity in the warehouse, typically accounting for more than half of the warehouse’s operating costs. Therefore it is important to monitor picking as a way to improve warehouse productivity. In the article “How to improve efficiency with the right Route & Warehouse KPIs” I explored the best KPIs to evaluate your warehouse efficiency. Today I will focus on the metrics you should monitor in the picking process to enhance your warehouse productivity.

Main Picking KPIs

Picking process metric 1: Pick volume by picker

This KPI reflects the number and value of orders picked by the pickers in a defined period. This index allows you to better manage your picking staff and determine which pickers need training, relocation and even termination.

Picking process metric 2: Order picking accuracy

This metric shows how accurately warehouse employees pick products for orders and is basically the ratio of wrong picks to total picks. The most common way to track this KPI is by staging the picked orders in a packing area, where somebody validates the pick list and does a visual scan on the order to ensure accuracy, so you can have a list of wrong picks. If you have a WMS the process is easier and more accurate, since you can scan the orders in the packing area and automatically compare them with the order in the system; then the list is also generated by the system.

Picking process metric 3: Average time to pick an order

This is the amount of time it takes to pick an order from the shelf and stage it in the packing area. Some distributors include the packing time in this time if it is done by the same person who picks the order. There are two factors that affect this index: the proficiency of the picker is one of them, but the main factor is the warehouse layout and the product slotting method. According to a research from the Georgia Tech Supply Chain and Logistics Institute, the most time-consuming part of the picking process is travel, which takes up 55% of picking time. For this reason, much of the work around improving order picking processes is aimed at reducing unproductive travel time. You can expand on this in my recent article on the subject.

Picking process metric 4: Direct cost of picking an order

This index combines the “time to pick an order” index with the labor cost. For example, if your average picker salary is $18/hour and the average pick time is 10 minutes, the direct cost of picking an order is $3. But if the picking time is reduced to 5 minutes, the picking cost per order would be $1.50.

Picking process metric 5: Partial Order Picking

With this index we keep track of the orders that were not entirely picked. Note that “accuracy” relates to picking the wrong items, while “completeness” refers to not picking some of the products in the order. The three main reasons for this are:

- Pick lower quantities

- Some of the items were missing (Human error)

- Lack of inventory of some of the items in the order

The effect of incomplete picking is devastating since it implies reprocessing, more than one trip to the customer, and customer dissatisfaction.

Picking process metric 6: Picking Efficiency

This index measures the orders picked over a period in both, quantity and value. This is the key index that reflects the overall picking process performance. Any deviation in any of the other KPIs presented, directly affects the picking efficiency: slower pickers, picking errors, deficient warehouse layout, and incomplete order picking, directly affect picking efficiency.

How to improve the picking process?

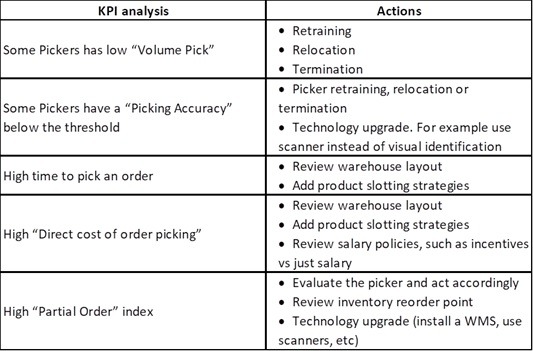

A careful and permanent analysis of the picking KPIs will give you information in how to improve your overall picking efficiency. The table below illustrates some of the possible actions.

I hope this article has been helpful to you on how improve warehouse productivity. I will continue to post information related to warehouse management, distribution practices and trends, and the economy in general. If you are interested in this article or want to learn more about Laceup Solutions, please subscribe to stay updated on future articles.

There is a lot of relevant information on our channel. Check out this video on this topic.

Sorry, the comment form is closed at this time.