Warehouse KPIs that good WMS software must have

In a previous article I went over the best set of KPIs for a distribution operation. Today I will focus on the basic warehouse KPIs that warehouse management software need to have to optimize overall warehouse performance.

What is a KPI?

Key Performance Indicators (KPIs) are the critical (key) indicators of progress toward an intended result. KPIs provide a focus for strategic and operational improvement, create an analytical foundation for decision making and help focus attention on what matters most. The primary difference between a KPI and a metric is that a KPI explains what is being measured, while a metric is the numerical value of the measurement itself.

A good set of KPIs will give you the tools to:

- Monitor the health of the company

- Measure the evolution of your goals

- Make proper adjustments and corrective action plans

- Solve problems and detect opportunities for improvement

- Analyze trends and patterns

One of the criteria when selecting your Warehouse Management System is the warehouse KPIs that are integrated into it.

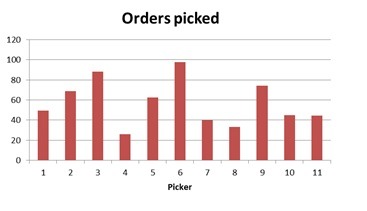

Basic warehouse KPIs: Picking Efficiency

Picking efficiency measures how many cases an individual picked in a given time frame. This warehouse KPI allows you to rank your pickers from most efficient to least efficient. Below is an example.

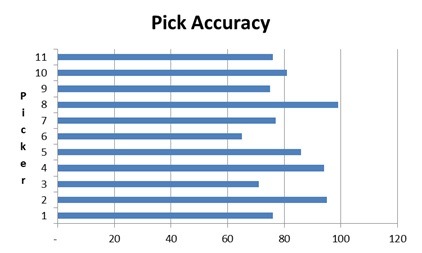

Basic warehouse KPIs: Picking Accuracy

Picking efficiency is useless without picking accuracy since you don’t want somebody who can pick a million boxes a minute, if 90% of them are inaccurate. It is extremely important that the checker modules of your warehouse management systems allow you to verify or check what was picked or spot check what was picked. Below is an example.

Basic warehouse KPIs: Inventory Accuracy

Inventory accuracy is how accurate your inventory is, and it is basically relative to the number of cycle counts you have to do. As I explained in “4 WMS triggers that will improve warehouse productivity”, a cycle count trigger occurs when there is a discrepancy between the quantities in the system and the actual quantities in the bin. So, inventory accuracy is the total adjustment made in one cycle count against the total inventory. This KPI tells you how careful your staff is in putting away products, transferring product, picking the right product, and how much theft you have.

Basic warehouse KPIs: Lost Sales

If you don’t have enough inventory in the warehouse to meet demand, you are missing out on sales opportunities. Many WMS do not keep track of this figure, but it is a very important metric. This key performance indicator shows you every single time you went to pick a product but couldn’t because it wasn’t there, and gives you a total dollar amount. Running this report weekly gives you an insight into what is going on with your inventory and product rotation.

I hope this article has been helpful to you when selecting a WMS. I will continue to post information related to warehouse management, distribution practices and trends, and the economy in general. If you are interested in this article or want to learn more about Laceup Solutions, please subscribe to stay updated on future articles.

There is a lot of relevant information on our channel. Check out this video on the subject.

Sorry, the comment form is closed at this time.