6 considerations to choose your new Warehouse location

Warehouse location has a profound impact on how effective, efficient, and profitable your distribution operation can be. In this article I will give you the 6 main factors I recommend you to consider when selecting your warehouse location.

Customer Base

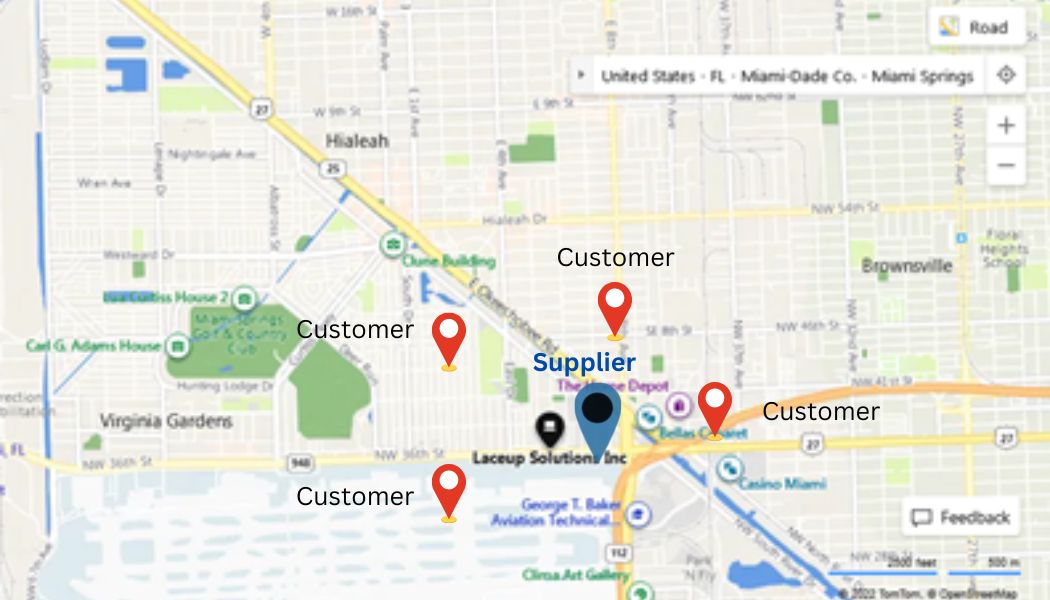

You need to assess where your customers are strategically located in the city before placing your warehouse. For example, if you are a distributor, mark all the stores you serve on a map, and find the customers that generate 80% of your revenue. Then put your warehouse as close to them as possible, so you can give them the best service possible. This criterion applies even if you are a nationwide company; in that case, you need to be located in a state that offers the lowest transportation cost for your top customers.

Supplier Network

The time it takes for your vendors to deliver an order to you is one of the elements to consider when determining the reorder point your products. Ergo, the closer you are to your main suppliers, the lower your stock needs will be. In fact, many of my distributors place their warehouses right next to their main supplier, so that they can do cross-docking. In this way they send a purchase order to the supplier, the supplier takes that purchase order and ships it because it is next door, and it may already come palletized and ready to load onto a truck for delivery to the customer.

Building availability and expandability

Building availability goes beyond immediate site selection. It also has to do with the capacity to allow you to grow. For example, let’s assume you manage to lease a location near your major customers and vendors. What happens if you increase your sales in 3 years and do not consider the capacity for expansion? You will end up looking for a second warehouse in a location that cannot support the previous criteria. As a general rule of thumb, I recommend assuming 20% growth per year and planning for a warehouse that will meet your growth projection for three years. So, if your current need is 10,000 SQF, consider a warehouse location of 17,280 SQF (10,000*1.2*1.2*1.2).

Lease rates, taxes and incentives

Rental or lease costs are obviously one of the main considerations when evaluating warehouse location. According to Statista, the average warehouse cost increased from $6.34 per SQF in 4Q20 to $7.13 in 4Q2021 (12.46% increase) and the trend continues in 2022. So, it is very important to consider rental rates in the selection of the state and area for your warehouse location. Within this context, you must also take a look at the incentives offered by some states to help the development of certain areas.

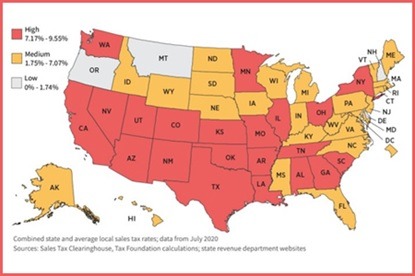

In addition to rental fees, tax structures also have a major impact on warehousing costs. When evaluating the state for your warehouse location, also consider the impact of local taxes, such as inventory tax and franchise tax, and personal taxes that affect employees, such as sales tax and property tax rates. For example, only Alaska, Florida, Texas and Washington have no state income tax, and the graph below pictures the sales taxes per state.

In addition to rental fees, tax structures also have a major impact on warehousing costs. When evaluating the state for your warehouse location, also consider the impact of local taxes, such as inventory tax and franchise tax, and personal taxes that affect employees, such as sales tax and property tax rates. For example, only Alaska, Florida, Texas and Washington have no state income tax, and the graph below pictures the sales taxes per state.

Workforce availability and cost

Warehouse workforce availability, skills and cost, directly impact the cost of your operation. Not all geographical locations offer a workforce with the right skills at the right price. The general impulse when hiring warehouse personnel, is to go for the cheapest but, as we explained in a recent article, the experience and training of a warehouse employee highly impacts warehouse efficiency. Therefore, when choosing a warehouse location, research demographics and focus on educational attainment, population characteristics and income levels.

Local environment Surroundings

Surrounding your warehouse location is also a factor to consider. Some states are more likely to be affected by natural forces. For example, the central states are more likely to experience tornadoes, while the southeastern states are more affected by hurricanes. Not to mention the wildfires in California and the earthquakes in the western states. But besides the natural environment, you should also look at the conditions surrounding your potential warehouse location. For example, I had a customer who closed an excellent deal on a site that met all of the above criteria, but… when it rained the entire surrounding area was flooded.

I hope this article has been helpful to you when selecting a WMS. I will continue to post information related to warehouse management, distribution practices and trends, and the economy in general. If you are interested in this article or want to learn more about Laceup Solutions, please subscribe to stay updated on future articles.

There is a lot of relevant information on our channel. Check out this video on the subject.

Sorry, the comment form is closed at this time.