Distribution center / Warehouse best practices

Running a warehouse in a distribution center or a factory is a very delicate and complex process. You need to balance cost and efficiency within a rapidly changing environment. In this article I will give you the 5 warehouse best practices that we have compiled throughout all our years working in this field.

Warehouse process

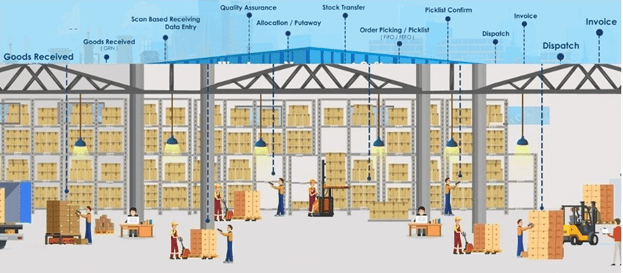

Before starting to dwell on warehouse best practices, let’s first review the typical warehouse process. The figure below illustrates the work processes of a warehouse accompanied by a brief description of each one.

Receiving: Warehouse receiving refers to the process of replenishment of inventory items. The receiving process involves the delivery of the products by the vendors and you unloading them from the delivery truck.

Labeling: A warehouse labeling system can help you keep track of all products as they move through each point of your operation (this includes labeling your containers as well as identifying labels for your aisles, warehouse racks and bins).

Put-away or check-in: Put-away refers to all the processes that occur between the receipt of the goods from the vendors and their storage in the assigned places. Having a put-away system simplifies the process of storing items, reduces the risk of misplacing or losing items, and keeps your warehouse clean and organized.

Sorting & Picking: The order picking or order preparation operation consists of taking and collecting articles in a specific quantity before shipping to satisfy customer orders. It is a basic warehousing process and has a major influence on supply chain productivity. This makes order picking one of the most controlled logistic processes.

Loading & Dispatch: One of the functions of a warehouse is to dispatch the merchandise sold. The goal is to ship the products ordered by customers so that they leave the facility and are delivered in the agreed time and in perfect condition.

Route Returns: When a customer returns a product, it is inspected by a warehouse worker to ensure it hasn’t expired and there are no missing parts. Once it passes quality control, it is restocked.

Distribution center / warehouse best practices

There is plenty of literature on how to optimize your warehouse or distribution operation. In this section we highlight the five practices that achieve the best results and, without which, you cannot have an efficient warehouse operation.

Warehouse best practices: #1 is to define your warehouse KPIs

Key Performance Indicators (KPIs) are the critical (key) indicators of progress towards an expected result. KPIs provide a focus for strategic and operational improvement, create an analytical foundation for decision making, and help focus attention on what matters most. The primary difference between a KPI and a metric is that a KPI explains what is being measured, while a metric is the numerical value of the measurement itself.

Warehouse best practices: #2 is to design your warehouse layout

There are three elements associated with the warehouse layout design that have an impact on the warehouse processes related to the movement of products. They are:

- Arrangement of the racks along the storage space

- Warehouse traffic flow along the storage area

- Product space allocation

In our two-part articles on warehouse layout, we fully explain these concepts

Warehouse best practices: #3 is to automate as much as you can

The more automated your processes are, the more reliable and efficient your operation will be. There are four types of automation that you should implement:

- Warehouse automation: When paired with lean warehouse management, a Warehouse Management System (WMS) integrated into your ERP will optimize warehouse operations at all levels. This includes ordering, receiving, storing, reordering, sorting, picking, packing and shipping. These improvements will be reflected in customer satisfaction and in the company´s net profit.

- Product ID automation: All warehouse processes require product identification. Assign barcode labels to products, cases, pallets, and warehouse locations, and use handheld barcode-scanning devices in all processes. This will improve warehouse efficiency and productivity.

- Route automation: Route Optimization is a very powerful tool that allows you to optimize routes based on proximity, traffic, your customers´ reception hours, and truck capacity. There is a tendency to associate “Route Management” with “Route Optimization Software”. But, in reality, Route Management combines optimizing route efficiency with real-time truck tracking, driver guidance to minimize distance to destination, and driver monitoring.

Warehouse best practices: #4 is to emphasize training

It typically takes a newly hired warehouse employee eight months to reach full productivity, and the latest figures from the Bureau of Labor Statistics put annual warehouse turnover rates at 43%. Considering that the warehouse operation is the heart of any distribution and industrial company, hence the importance of an effective training program for warehouse employees. Warehouse employees who are not properly trained lead to costly mistakes and high rework time. That´s why you need to dedicate all available resources to ensuring your new hires are well-trained when they start doing their jobs, and a good follow-up process aimed at reducing errors along the learning curve.

Warehouse best practices: #5 is to define your cycle count

A cycle count is a perpetual inventory audit procedure, in which you follow a sequence of checks that is repeated periodically on a subset of the inventory. Cycle counts require less downtime than physical inventory and help identify minor problems and inaccuracies before they become major issues. Because cycle counts are performed regularly, you can spend less time doing physical counts and more accurately track inventory. This leads to increased productivity and vastly improved stock management and re-order process.

I hope this article has been helpful to you. I will continue to post information related to warehouse management, distribution practices and trends, and the economy in general. If you are interested in this article or want to learn more about Laceup Solutions, please subscribe to stay updated on future articles.

There is a lot of relevant information on our channel. Check out this video related to warehousing.

Sorry, the comment form is closed at this time.