Order picking methods

In my last article on distribution best practices, I mentioned that selecting the most adequate picking method is one of the topics that all distribution operations take very seriously, given the enormous amount of labor and associated costs. In this article, I describe the different order picking methods you can use and the type of operation typically associated with each.

Picking and warehouse processes

Picking is at the core of the wholesale and distribution operation processes related to order fulfillment, as illustrated below. Depending of the type of operation you have and the way you have designed these processes, you will elect the combination of picking methods that best suits your needs.

Order picking methods

There are several ways to pick products in a warehouse. In this section I explain the 5 methods that I consider more relevant.

Single picking

Single order picking is the most widely used method, especially for small operations, but it is also the most inefficient and time consuming. In this method, the warehouse employee picks one order at a time, which involves pickers walking up and down the warehouse several times during their shift. To illustrate why this method can be inefficient, suppose there are two orders to be picked, blue and black in the image below. With single picking, the picker will have to travel the same route twice.

Batch picking

In batch order picking, orders that have products in common are grouped into a “batch” and assigned to a picker who will pick the items in all orders in the batch. For example, suppose there are 4 orders that contain the following:

In batch picking, the three orders can be grouped and assigned to a picker to pick them simultaneously, thus saving time. This method works best for operations with a small number of SKUs. The batch method requires a WMS with the ability to group orders and generate a batch list. The main drawback of batch picking is that it is prone to human error, as the picker is working on more than one order at the same time on the same container.

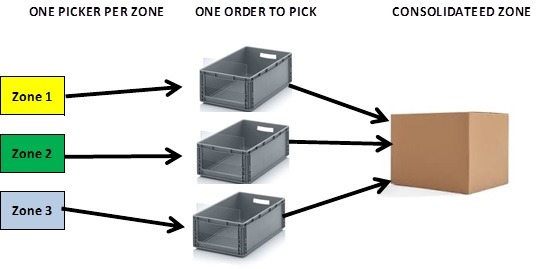

Zone Picking

Larger distribution operations sometimes divide the warehouse into zones, each containing products with similar characteristics, such as frozen products, low shelf life items, etc., and use the zone picking method, also called pick & pass. In this method, each picker has an assigned zone and simply passes the order to the next zone once they have picked the order item in their zone, as illustrated below.

Wave Picking

Wave picking also operates with zones, but in this method a given item is picked for all orders for that day and placed in a “consolidation” zone, where individual orders are then completed. For example, suppose you have 25 orders to deliver today, and item 001 is on 10 of them; you then pick the total quantity of item 001 at once and place them in the consolidation area to be fulfilled when all items on the orders are also picked.

This picking method works for warehouses that handle many orders per day and with a WMS with scheduling and “suggested picking route” features. Organized correctly, wave picking saves picking time, but may require more workers.

Cluster picking

Cluster picking is similar to the wave method in the sense that workers pick items from multiple orders at the same time, but instead of concentrating on one item for all orders, they pick several SKUs from multiple orders. Cluster pickers normally have a cart with multiple containers, each representing an order, like the one below, and can use advanced technology on site.

Cluster picking is very popular for eCommerce fulfillment or for operations with many orders to fulfill per day and a small number of SKUs for al items on the orders.

I hope this article has been helpful to you. I will continue to post information related to warehouse management, distribution practices and trends, and the economy in general. If you are interested in this article or want to learn more about Laceup Solutions, please subscribe to stay updated on future articles.

There is a lot of relevant information on our channel. Check out this video related to the subject.

Sorry, the comment form is closed at this time.