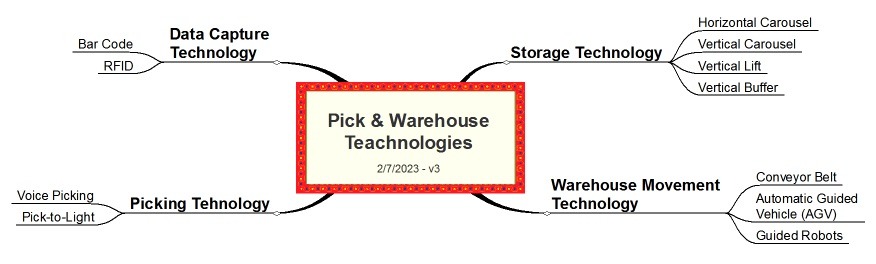

Picking and warehouse technology

In my last article on “Order picking methods”, I covered the different ways you can structure the picking of orders in your warehouse. In this article, I will describe the picking and warehouse technology that has been developed to support distribution center automation.

Why incorporate picking and warehouse technology

We have mentioned in other articles that picking orders is the most time consuming and expensive of all warehouse processes, and also the main source of order fulfillment errors ; with movement of inventory in and out of the center being the second. This is why distribution companies start incorporating picking and warehouse technology as they grow.

he range of tools that support picking optimization is broad and comprises software and hardware systems. We have gone over the different types of software that help reduce time and errors. In the reminder of this article I will elaborate on the hardware technology that is available to assist in picking and warehouse movement.

Issues to consider when deciding the incorporation of warehouse technology

The use of technological solutions can be very beneficial, but it can be expensive. That is why we always recommend a detailed assessment of the benefits versus the investment before deciding to incorporate systems and the type of technology to use. It is important to note that any of the technological systems described in this article require a warehouse management system to supports them.

This is a list of the issues you must consider.

- Number of different SKUs and their packing

- Way to store the products: full-pallet, layer, case, etc.

- Size and layout of the warehouse.

- Picking method (discussed in the last article).

- Existing software systems (ERP, WMS, etc.).

- Size and type of the order.

- Distribution channel mix: retail, wholesale, e-commerce

Picking and warehouse technology available

We can group the different technologies developed for distribution center automation into four categories, depending on the type of process intended to be automated. They are:

- Storage system technology

- Data capture technology

- Picking location technology

- Warehouse movement technology

Let’s describe each of these categories.

Storage system technology

This type of warehouse technology is applied to the physical storing system and has two benefits:

- Reduce storage space

- Reduce product retrieval and storage time.

There are several racking systems to choose from, depending on the size and volume of your storage unit, and the warehouse layout. The most common are:

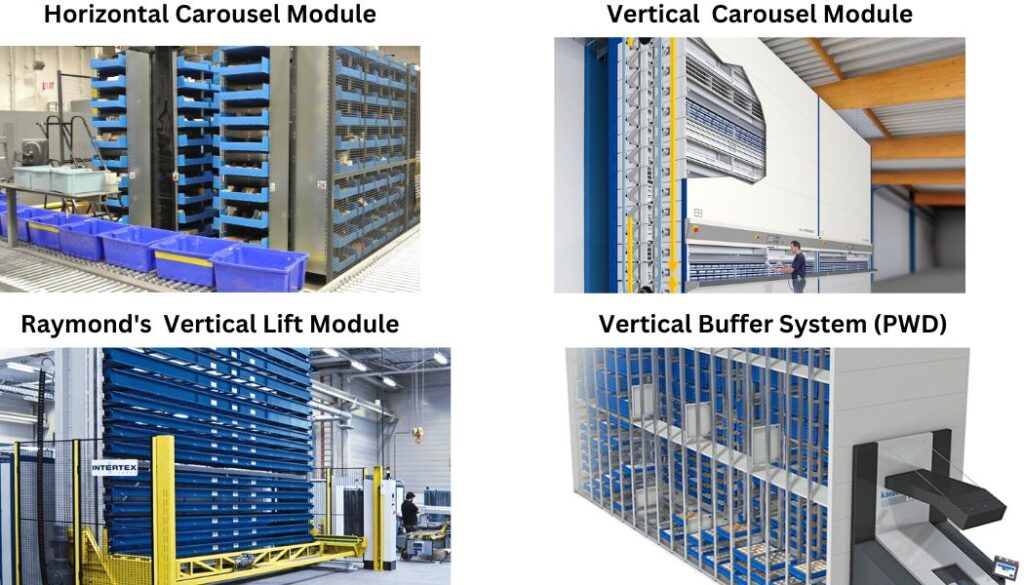

Horizontal Carousel Modules: Consists of bins mounted on an oval track that rotate horizontally to deliver stored items to an operator.

Vertical Carousel Modules: They are shelves that revolve around a track in a Ferris wheel fashion.

Vertical Lift Modules (VLM): This system has two columns of trays with a central inserter/extractor that automatically locates and retrieves stored trays from both columns.

Vertical Buffer System: This is a fully enclosed bin handling system that uses automatic height sensing to compactly store and retrieve trays and bins.

Below is a picture of a representative equipment of each of these systems.

Data capture technology

These types of technology are intended to gather information of products and location in a distribution center. The two most used are: Bar Code Scanning and RFID (Radio Frequency ID) scanning technology. You can learn more about this in the video at the end of the article.

Picking location technology

This technology reduces picking time by quickly and accurately indicating the picker where the items to be picked are located. This technology allows the picker to operate hands-free and reduces the learning curve of the operators regarding item location. The two most used are:

Voice picking: With voice picking, pickers receive verbal instructions on which items to pick and their locations in real-time.

Pick-to-light: This technology consists of a series of LEDs of different colors installed along the rails of the rack, and associated with the SKU of the products stored in each location. When the picker scans the code of the item to be picked, the LEDs where that SKU is stored will light up.

Warehouse movement technology

There are several technologies used to move inventory within the warehouse: from receiving, storage, picking, consolidation, packing, and shipping.

Conveyor belts: They can be horizontal or vertical and can be designed to move few, small items typical of ecommerce, or palletized cargo. Zone picking methods benefit from this type of equipment to move the products between zones.

Automatically Guided Vehicles (AGVs): AGVs are portable robots that move around the warehouse following long lines or wires marked on the floor. They can use radio waves, vision cameras, magnets, or lasers for navigation.

Guided Robots: This is also a robotic solution but, unlike AGVs that follow fixed paths, guided robots follow a route based on a map of the facility embedded into it or in a software, very much like the GPS of a car defines the route for a given destination.

I hope this article on warehouse technology has been helpful to you. I will continue to post information related to warehouse management, distribution practices and trends, and the economy in general. If you are interested in this article or want to learn more about Laceup Solutions, please subscribe to stay updated on future articles.

There is a lot of relevant information on our channel. Check out this video related to data capture technologies.

Sorry, the comment form is closed at this time.