How should work a pharmaceutical warehouse management system?

Managing a pharmaceutical warehouse requires meticulous attention to detail and an efficient system to ensure that raw materials and finished products are stored and distributed correctly. In this blog, I will cover key elements of an effective pharmaceutical warehouse management system, including the essential features it should have and the benefits for the company.

Importance of WMS in the pharmaceutical industry

The pharmaceutical industry is highly regulated, and manufacturers must adhere to strict regulations regarding the storage, handling, and distribution of their products. Therefore, efficient warehouse management is crucial to the success of pharmaceutical companies. A pharmaceutical warehouse management system (WMS) can help companies manage their inventory, supply chain, and logistics more effectively.

Essential features of a pharmaceutical warehouse management system

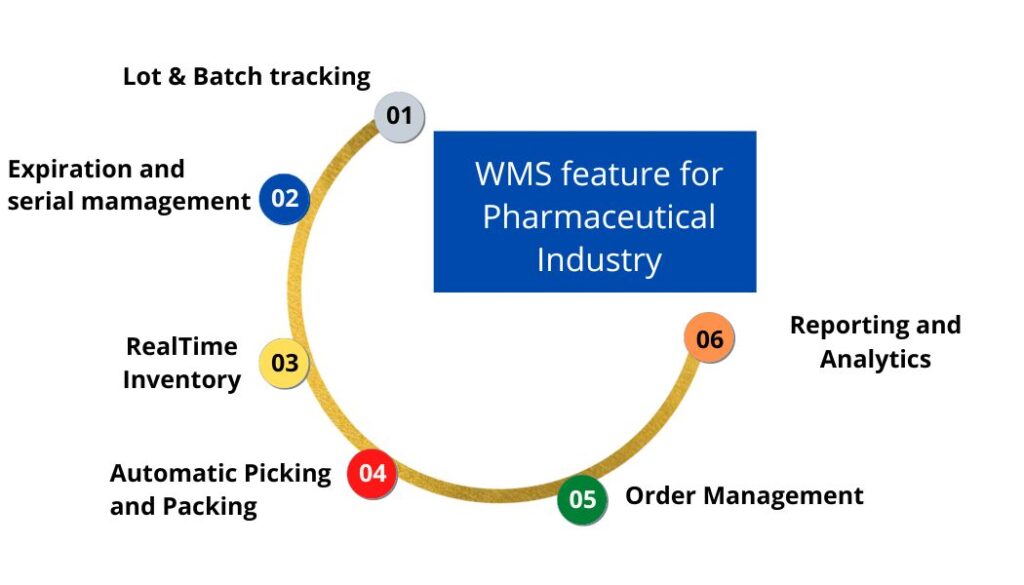

A warehouse management system (WMS) for the pharmaceutical industry should have several features to effectively manage inventory, warehouse operations, and comply regulation. Here are some of them:

- Lot and batch tracking: In the pharmaceutical industry, lot and batch tracking are crucial to ensure that products are not mixed and that any quality or safety issues can be traced back to the source. The WMS should have the capability to track lot and batch numbers for each product.

- Expiry date management: The WMS should manage expiry dates for products in the warehouse to ensure that expired products are not shipped to customers or used to make the products. The system should be able to alert warehouse staff to products that are approaching their expiry dates.

- Serialized inventory management: In the pharmaceutical industry, serialized inventory management is critical to ensure that each product has a unique serial number that can be tracked throughout the supply chain. The WMS should be able to assign and track serial numbers for each product.

- Real-time inventory visibility: The WMS should provide real-time visibility of inventory levels, locations, and movements. This allows warehouse staff to manage inventory more accurately and efficiently.

- Automated picking and packing: The WMS should automate the picking and packing process to increase efficiency and accuracy. The system should be able to direct warehouse staff to the appropriate locations to pick items and provide instructions on how to pack them.

- Audit trails and compliance reporting: The WMS should provide audit trails and compliance reporting to ensure that warehouse operations comply with regulatory requirements. The system should be able to track inventory movements, lot and batch numbers, and other information required for compliance reporting.

- Order management: The WMS should manage the processing of customer orders, from order entry to shipment. The system should provide real-time tracking of orders and alert customers if there are any delays or issues.

- Reporting and analytics: The WMS should provide reporting and analytics capabilities to track warehouse performance, inventory levels, and customer orders. These reports can be used to identify areas for improvement and make informed business decisions.

Benefits of a pharmaceutical warehouse management system

A pharmaceutical Warehouse Management System with the features listed above, like our WMS, can provide numerous benefits to pharmaceutical companies, including:

- Improved inventory accuracy: Accurate inventory management is particularly important in the pharmaceutical industry, where expired or damaged products can be costly and potentially dangerous. With WMS, pharmaceutical companies can have real-time visibility of their inventory levels, locations, and movements. This helps them to manage inventory more accurately, either from bulk raw material as well as finished products, reducing the risk of stock shortage or overstocking.

- Reduced waste: By providing accurate inventory data, WMS helps pharmaceutical companies to reduce waste caused by expired or damaged products, and wrong-handling raw material.

- Faster order processing: A pharmaceutical warehouse management system can automate many of the warehouse processes, including receiving, put-away, picking, and shipping. This results in faster and more accurate order processing, which is crucial in the pharmaceutical industry, where time-sensitive products must be delivered quickly and efficiently.

- Increased efficiency: A pharmaceutical warehouse management system optimizes warehouse layout, storage, and picking strategies. By using WMS, companies can reduce travel time and improve the utilization of warehouse space. This can lead to increased efficiency, reduced labor costs, and improved customer service.

- Improved customer service: By using WMS, pharmaceutical companies can provide better customer service by reducing delivery times, improving order accuracy, and providing real-time order tracking.

I hope this article has been helpful to you. I will continue to post information related to warehouse management, distribution practices and trends, and the economy in general. If you are interested in this article or want to learn more about Laceup Solutions, please subscribe to stay updated on future articles.

There is a lot of relevant information on our channel. Check out this video on the way the WMS helps one of the most important Vitamin manufacture in production and raw material handling.

Sorry, the comment form is closed at this time.