Strategies for Faster and More Accurate Picking

In recent articles I talked about picking methods and picking process. It is clear that the fast and accurate picking can significantly impact customer satisfaction and overall productivity. In this article, I will discuss various strategies to enhance the picking speed and accuracy.

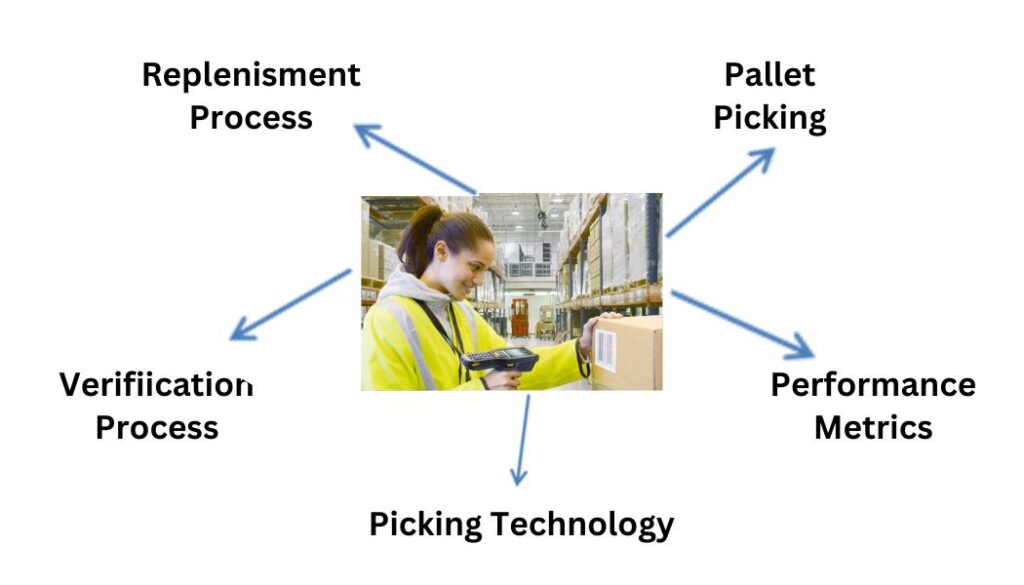

What processes has the major incidence in an accurate picking?

There are five processes or tasks that have the highest impact on accurate picking and speed.

Strategies to improve speed and accuracy in picking

Prioritize Replenishment

One of the fundamental aspects of improving picking speed is efficient replenishment. Often overlooked, this crucial step sets the foundation for a smooth picking process. Here are some key considerations.

Implementing Two Shifts: To maximize efficiency, consider adopting a two-shift approach. One shift focuses on receiving, palletizing, put-away, replenishment, and cycle counts, while the other is solely for picking. This strategy ensures that the pickers begin their shifts with fully replenished stock, eliminating the need for forklifts in the picking aisles and streamlining the picking process.

Leveraging Existing Systems: For those warehouses that do not have a WMS, printing reports from an existing Enterprise Resource Planning (ERP) system can provide valuable insights. These reports should display product information and the quantity required for each day’s orders, enabling informed replenishment decisions.

Rethink Pallet Picking

Traditional pallet picking, where orders are picked one at a time and added sequentially to a pallet, can be time consuming. To accelerate the process, consider alternative methods:

Pallet Jacks with Double Pallet Capacity: Pallet jacks designed to carry two pallets can significantly reduce picking time. This approach allows pickers to double their efficiency when navigating the warehouse, cutting down on unnecessary trips.

Use Carts for Individual Orders: Some warehouses opt for a cart-based approach when picking individual orders. These specialized carts often feature multiple tiers and closing cages, enabling pickers to collect items for several orders simultaneously. This method dramatically reduces the number of trips required to complete picking tasks.

Implement Performance Metrics

Motivating pickers to work efficiently is essential for achieving higher picking speeds. One effective strategy is to introduce performance metrics:

Case Count Metrics: Measure how many cases each picker can process throughout their shift. Displaying these metrics on a scorecard in the warehouse allows employees to see their progress and fosters healthy competition.

Incentives and Commissions: Consider offering incentives and commissions to pickers who consistently perform above the set goal. This practice can be a powerful motivator to increase productivity.

Accurate Picking Is Non-Negotiable

Accurate picking is just as vital as speed, as errors can lead to customer dissatisfaction and increased costs. Here’s how to ensure accuracy:

Checking Process: Implement a checking process alongside picking to verify the accuracy of orders. Checkers can follow pickers along their routes or inspect completed pallets or carts to ensure that the correct items have been selected.

Cost vs. Benefit of Checkers: While some businesses may be concerned about the cost of employing checkers, it is crucial to weigh this against the expenses associated with errors. These may include customer fines, increased fuel costs, and decreased employee and customer morale. In many cases, the cost of errors far exceeds the expense of hiring checkers.

Picking Technology

Although we have addresses picking and warehouse technology in the past, there are two strategies that are a most to optimize picking.

Embrace scanner technology: Scanners ensure the right product is picked and moved between bins and help pickers select the correct item from the right location.

Product location: A WMS with a product location feature in essential to optimize picking route and picking order.

I hope this article on speed and accurate picking has been helpful to you. I will continue to post information related to warehouse management, distribution practices and trends, and the economy in general. If you want to know how Laceup’s solutions can help you with e-commerce, click the link below to schedule an exploratory meeting.

There is a lot of relevant information on our channel. Check this video related with today’s subject.

Sorry, the comment form is closed at this time.