Inventory Forecasting Techniques in Distribution and Wholesale: Optimizing Stock Levels

Inventory management is the backbone of distribution and wholesale businesses. To be successful and profitable in these industries, it is essential to have the right products in the right quantities at the right time. In this article, I explore how different inventory forecasting methods can help distribution and wholesale companies anticipate demand, optimize stock levels, and maintain a competitive edge in their respective markets.

The Significance of Inventory Forecasting in Distribution and Wholesale

Inventory forecasting is a strategic process that involves predicting future demand for products based on historical data and market trends. For distribution and wholesale businesses, accurate forecasting provides several critical advantages:

Efficient Supply Chain Management: Proper forecasting helps streamline the supply chain by ensuring that products are available when needed, minimizing delays, and reducing operational costs.

Inventory Cost Control: It prevents overstocking, which can tie up capital and lead to storage costs, and it helps prevent understocking, which can result in missed sales opportunities.

Customer Satisfaction: Accurate forecasting ensures that popular items are consistently in stock, enhancing customer satisfaction and loyalty.

Inventory forecasting Techniques

Let’s get into different forecasting techniques tailored for distribution and wholesale:

Historical Sales Data Analysis:

Distribution and wholesale businesses can start by analyzing historical sales data or sales trends. This approach helps identify trends and seasonal patterns specific to their product lines. Historical data is invaluable for short-term forecasting, especially for well-established products.

Demand Aggregation:

Demand aggregation can be effective in distribution and wholesale, where large quantities are involved. This method combines demand forecasts for multiple products, allowing businesses to optimize bulk ordering and negotiate better terms with suppliers.

Collaborative Forecasting:

This method involves working with customers and suppliers to develop a joint forecast. Collaborative forecasting can be helpful in situations with a high degree of uncertainty about future demand, like the release of a new product or category.

Safety Stock Analysis:

Safety stock analysis helps distribution and wholesale companies plan for unexpected fluctuations in demand. By setting aside a safety stock buffer, businesses can mitigate the risks of stockouts during peak demand periods.

Advanced Analytics and Machine Learning:

Leveraging advanced analytics and machine learning technologies allows distribution and wholesale companies to analyze vast datasets, including market trends, competitor behavior, and economic indicators. These insights lead to more dynamic and precise demand predictions but are complex and expensive.

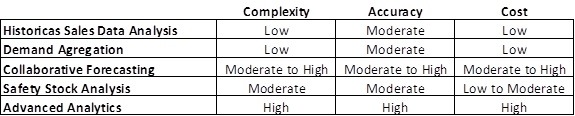

Pros and Cons of the different Techniques

LaceUp Solutions

LaceUp Solutions DSD and WMS software support demand forecasting. In WMS store order forecast feature we described one of them. If you want to know how Laceup’s solutions can help you with inventory optimizations, click the link below to schedule an exploratory meeting.

I hope this article has been helpful to you. I will continue to post information related to warehouse management, distribution practices and trends, and the economy in general.

There is a lot of relevant information on our channel. Check this video with tips to make your distribution company more profitable.

Sorry, the comment form is closed at this time.