Retail Store Stockouts: Causes,Effects and How To Avoid It

Out-of-stock products are a complex issue with far-reaching consequences. However, by understanding the causes and implementing effective solutions, retailers can minimize their occurrence, ensuring happier customers and higher sales. This article explores the causes and effects of retail store stockouts, providing insights into how they can be managed and mitigated.

What are Stockouts?

A stockout, also known as an out-of-stock situation, occurs when a retailer or supplier does not have enough quantity of a specific product to meet customer demand. This means that customers who want to purchase the product cannot do so because it unavailable on the shelves or in the inventory.

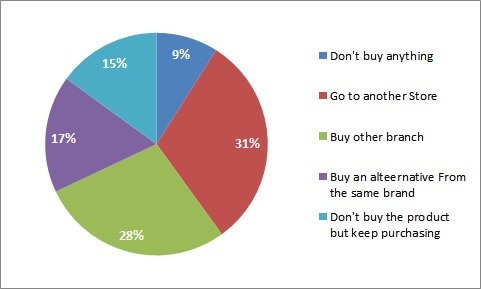

Customers Reaction to Retail Store Stockouts

Customer reactions to stockouts can vary depending on several factors, but studies from Harvard Business Review suggest that stockouts can lead to sales losses of 4% for a typical retailer, with nearly half of intended purchases abandoned when customers can’t find the desired item. Here are some interesting statistics to consider:

Causes of Retail Store Stockouts

Out-of-stocks are rarely due to a single factor. It is a combination of different factors that create this undesirable condition. Here are some of the causes:

Demand Forecasting Errors: Inaccurate predictions of customer demand can lead to either excess inventory or stockouts. Retailers may underestimate the popularity of a product, resulting in insufficient stock levels.

Supply Chain Disruptions: Issues such as delays in manufacturing, transportation problems, or supplier shortages can interrupt the flow of goods to the store, leading to stockouts.

Inventory Management Inefficiencies: Poor inventory management practices, like inadequate reorder points or failure to monitor stock levels, can result in products running out unexpectedly.

Seasonal Fluctuations: Certain times of the year, like holidays or back-to-school seasons, can see a surge in demand for specific products, leading to stockouts if retailers are not prepared.

Promotions and Sales: High-demand periods driven by promotions or sales can deplete inventory quickly, resulting in stockouts if restocking is not timely.

Effects of Stockouts

The consequences of retail store stockouts go far beyond just an annoyed customer.

Lost Sales: The most immediate effect of a stockout is lost revenue. Customers unable to find the product they want may leave without making a purchase.

Customer Dissatisfaction: Stockouts can lead to frustration and disappointment, potentially damaging the retailer’s reputation and leading to a loss of customer loyalty.

Increased Operational Costs: Attempting to resolve stockouts can incur additional costs, such as expedited shipping or overtime pay for employees restocking shelves.

Missed Opportunities: Stockouts can lead to missed opportunities for cross-selling or upselling, as customers may not spend as much time in the store or may leave altogether.

Competitive Disadvantage: Frequent stockouts can drive customers to competitors who have better inventory availability, leading to a loss of market share.

Preventing Retail Store Stockouts

Here are some strategies retailers can employ to minimize the occurrence of stockouts:

- Effective Inventory Management: Implement an inventory management system that provides real-time visibility into stock levels, regularly review and adjust reorder points and safety stock levels based on sales trends and lead times.

- Accurate Demand Forecasting: Use historical sales data, market trends, and predictive analytics to forecast demand more accurately. A DSD system with forecasting capabilities helps ordering the right amount of stock to meet customer needs without overstocking.

- Supplier Relationship Management: Develop strong relationships with suppliers to ensure reliable and timely deliveries. Communicate regularly about demand forecasts and any potential changes to ensure they can meet your inventory needs.

- Flexible Supply Chain: Build a flexible supply chain with multiple suppliers or alternative transportation options to quickly respond to unexpected disruptions or spikes in demand.

- Monitoring Trends and Seasonality: Keep an eye on market trends, seasonal fluctuations, and upcoming events that might affect demand. Adjust inventory levels accordingly to prevent stockouts during peak times.

- Training Staff: Train staff to understand the importance of inventory management and how to properly handle stock. This includes proper shelving techniques, timely restocking, and accurate record-keeping.

Laceup Solutions integrated suite of products can help in optimizing your inventory and preventing out of stock situations. If you want to learn more, give us your information to schedule a meeting.

I hope this article has been helpful to you. I will continue to post information related to warehouse management, distribution practices and trends, and the economy in general.

There is a lot of relevant information on our channel. Check this video on Tips To Make Your Distribution Company More Profitable.

Sorry, the comment form is closed at this time.