WMS Processes Part 1: The Receiving Process in a WMS

Warehouse Management Systems (WMS) play a pivotal role in optimizing operations within a warehouse. This is the first delivery of a series of articles on the components of a WMS and how they should work. I will start with the receiving process, since the efficiency and accuracy of receiving items significantly impact the overall performance of the warehouse.

Importance of the Receiving Process

Receiving does not refer only to a purchase order received. It applies to any item entering the warehouse, be it a PO, a transfer order from another warehouse, or returned items, and it is the base for all subsequent warehouse activities. It encompasses the physical receipt of goods, their inspection, and their entry into the WMS. Errors or delays in this process can lead to inaccuracies in inventory records, leading to issues like stockouts, overstocking, and order fulfillment errors.

Key Features of the Receiving Process in WMS

Advance Shipment Notifications (ASN): ASNs provide prior information about incoming shipments, including details like expected arrival time, contents, and quantity, allowing for preparedness and resource allocation.

Barcode Scanning: Products are scanned upon arrival using barcode or RFID technology, ensuring quick and accurate capture of product information and reducing manual data entry errors.

Receiving Items: The WMS should provide detailed information about the nature of the items received, whether they are individual items, pallets, or mixed pallets. It also indicates the quantity of each item or pallet received, allowing for accurate inventory management and planning.

Quality Inspection: Goods are inspected for damage, quality, and compliance with the purchase order, with any discrepancies recorded in the WMS for prompt resolution.

Put-away Management: The WMS facilitates efficient put-away by suggesting optimal storage locations based on predefined rules, such as product characteristics and space availability.

Integration with Purchase Orders: The WMS integrates with the purchase order system to match received goods against orders, ensuring accuracy in what was ordered versus what was received.

Most Common Deficiencies of a WMS Resulting in Errors during Receiving

Inadequate Integration with Suppliers: Poor integration with suppliers can lead to incorrect or delayed Advance Shipment Notifications (ASNs), causing disruptions in the receiving process.

Limited Barcode or RFID Capabilities: A WMS with limited capabilities for barcode or RFID scanning can result in manual data entry, increasing the likelihood of errors.

Poor Quality Inspection Protocols: If the WMS does not have robust protocols for quality inspection, damaged or non-compliant goods may go unnoticed, leading to inventory inaccuracies.

Inefficient Put-away Processes: A WMS with suboptimal put-away management can cause delays and errors in storing received goods, affecting the overall efficiency of the warehouse.

Lack of Real-time Inventory Visibility: A WMS that does not provide real-time visibility into inventory levels can result in discrepancies between physical stock and system records.

Inadequate Training and User Interface: If the WMS has a complex user interface or if the staff is not adequately trained, errors are more likely to occur during the receiving process.

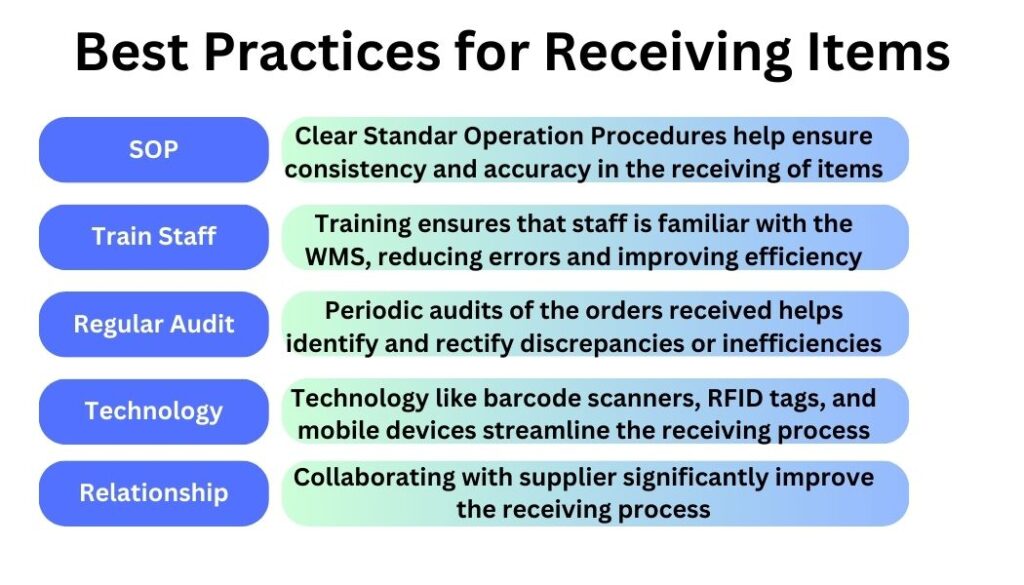

Best Practices for Receiving Items

The figure illustrates the best practices associated to the receiving portion of a WMS.

Conclusion

The receiving portion of a Warehouse Management System is crucial for maintaining accurate inventory records and ensuring the smooth functioning of subsequent warehouse operations. Laceup WMS have all the features required to optimize their receiving process, leading to improved efficiency and accuracy in the warehouse management. If you want to learn more, give us your information to schedule a meeting.

I hope this article has been helpful to you. I will continue to post information related to warehouse management, distribution practices and trends, and the economy in general. There is a lot of relevant information on our channel. Check this video on a live demo of the receiving process.

Sorry, the comment form is closed at this time.