Warehouse Safety Measures Ensuring a Safe Working Place

Warehouses are the backbone of many industries, serving as hubs for storage, shipping, and receiving goods. However, they can also be hazardous environments. Implementing effective warehouse safety measures is crucial to ensuring a safe and efficient working environment. In this article, I will discuss common warehouse hazards, highlight essential safety protocols, and provide measures to prevent accidents and ensure a secure operation.

Hazards to Prevent

Warehouses present a variety of hazards, including:

Forklift Accidents: Forklifts are essential in warehouse operations but can be dangerous if not operated correctly. Proper training and adherence to safety guidelines are vital.

Slips, Trips, and Falls: These are common in warehouses due to spills, uneven surfaces, and cluttered walkways. Maintaining clean and clear aisles is essential.

Falling Objects: Improperly stored items can fall and injure workers. Proper storage techniques and personal protective equipment (PPE) can help prevent these accidents.

Ergonomic Injuries: Repetitive motion and heavy lifting can cause long-term musculoskeletal disorders. Ergonomic solutions and lifting aids can reduce these risks.

Fire Hazards: Flammable materials, electrical issues, and improper storage of hazardous chemicals can all contribute to fire risks.

Warehouse Safety Protocols and Measures

Training and Awareness: Regular safety training is essential. Educate staff on hazard identification, safe lifting techniques, proper use of Personal Protective Equipment (PPE), and emergency procedures.

Warehouse Layout and Housekeeping: Warehouse layout is essential for an efficient operation. Maintain clear walkways, designated traffic lanes for forklifts and pedestrians, and well-organized storage areas. Post clear signage for exits, emergency equipment, and hazardous materials.

Material Handling: Enforce weight limits for lifting and carrying. Train employees on proper lifting techniques and encourage the use of mechanical lifting aids for heavy objects.

Forklift Safety: Ensure only certified operators drive forklifts. Conduct regular inspections of forklifts and enforce safe driving practices, including wearing seatbelts, maintaining safe speeds, and signaling turns.

Fall Protection: Use guardrails and safety netting around mezzanines and elevated platforms. Train employees on safe ladder use and proper fall arrest procedures.

Fire Safety: Implement a comprehensive fire safety program that includes regular fire drills, properly storing flammable materials, and accessible fire extinguishers.

Regular Inspections: Regularly inspect equipment, electrical systems, and warehouse facilities to identify and address potential hazards before they cause accidents.

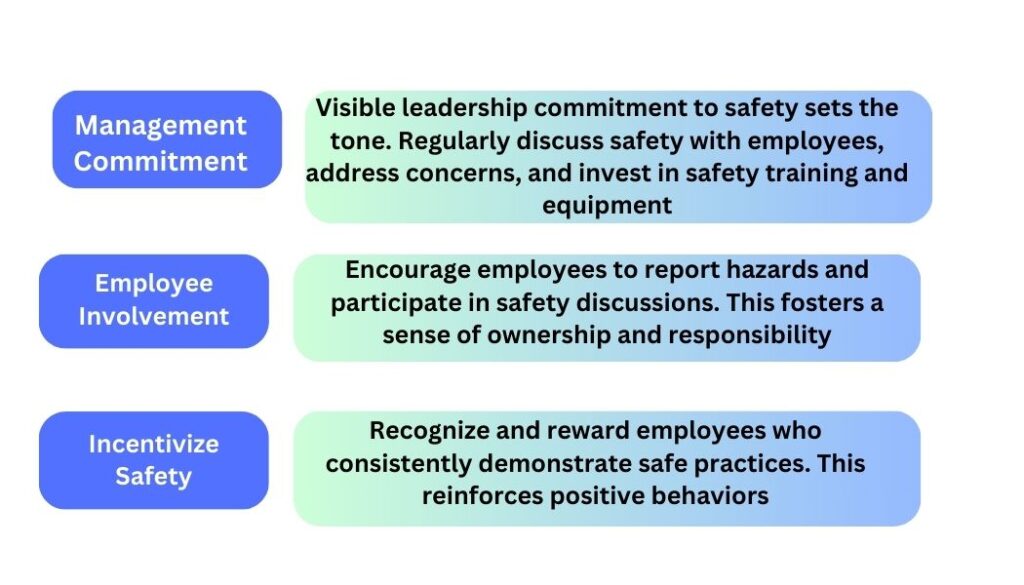

Building a Culture of Safety

Warehouse Safety goes beyond protocols and measures. It requires a cultural shift where everyone prioritizes safe practices. Here are some tips:

Conclusion

Implementing these warehouse safety measures and cultivating a culture of safety can significantly reduce the risk of accidents and injuries. These measures protect your employees and improve efficiency and overall warehouse operations. Remember, a safe warehouse is a productive warehouse. Invest in safety today and reap the rewards of a healthier, happier, and more productive workforce. To learn more about our solutions, click on the link below.

I hope this article on warehouse safety has been helpful to you. I will continue to post information related to warehouse management, distribution practices and trends, and the economy in general. Our channel has a lot of relevant information. Check out this video on another type of protection: ways your drivers are stealing from you.

Sorry, the comment form is closed at this time.