Lot Traceability: Ensuring Food Safety Across the Supply Chain

Lot traceability is the ability to track and trace the movement of goods throughout the supply chain, from raw materials to finished products. In the food industry, lot tracking is critical for ensuring food safety and compliance with regulations. In this article, we will explore the importance of lot traceability, its benefits, and the new FDA regulation that affects the food industry.

What is Lot Traceability?

Lot traceability refers to tracking and documenting the production history, location, and distribution of a product batch or lot. This process involves recording and managing information at each stage of the supply chain, from raw material sourcing through production and distribution to the end consumer. Effective traceability systems ensure every product can be traced back to its origin, providing critical data for quality control, inventory management, and regulatory compliance.

The Importance of Lot Traceability

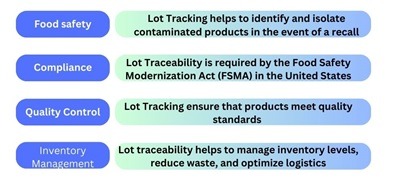

Lot tracking is essential for several reasons:

New FDA Regulation

In response to growing concerns about food safety and the need for more robust traceability systems, the U.S. Food and Drug Administration (FDA) has introduced new regulations aimed at enhancing traceability in the food industry. These regulations, part of the FDA’s New Era of Smarter Food Safety initiative, mandate more comprehensive traceability practices across the supply chain, promising a future of improved food safety and consumer confidence.

Key Provisions of the New FDA Regulation

- Enhanced Record-Keeping: The regulation requires businesses to maintain detailed records of critical tracking events (CTEs) and key data elements (KDEs) throughout the supply chain. This includes data on food products’ origin, processing, and distribution.

- Standardized Data: The FDA mandates using standardized data formats and terminology to facilitate traceability. This standardization ensures consistency and interoperability across different systems and organizations. The FDA mandates using standardized data formats and terminology to facilitate traceability. This standardization ensures consistency and interoperability across different systems and organizations.

- Traceability Plans: Companies must develop and implement traceability plans outlining their procedures for tracking and tracing food products. These plans should detail how data will be collected, stored, and shared with regulatory authorities when necessary.

- Rapid Response: The regulation emphasizes the importance of rapid response in the event of a food safety issue. Businesses must be able to quickly provide traceability information to the FDA and other stakeholders to facilitate timely recalls and prevent further distribution of contaminated products.

Implementing Effective Lot Control Systems

To comply with the new FDA regulation and enhance overall supply chain management, businesses should consider the following best practices for implementing lot traceability systems:

Invest in Technology: Modern traceability systems leverage technologies such as barcoding, RFID, and blockchain to efficiently capture and manage traceability data. These technologies enable real-time tracking and provide a secure, immutable record of product history.

Standardize Processes: Establish standardized processes for capturing and recording traceability data at each stage of the supply chain. Consistency in data collection and management ensures accuracy and reliability.

Collaborate with Partners: Work closely with suppliers, manufacturers, and distributors to ensure that traceability practices are aligned across the supply chain. Collaboration and data sharing are essential for comprehensive traceability.

Regular Audits: Conduct regular audits of your traceability system to identify and address any gaps or weaknesses. Continuous improvement is key to maintaining effective traceability and compliance.

Conclusion

With the new FDA regulation on lot traceability, businesses, particularly in the food industry, must adopt more robust and standardized traceability practices to ensure safety and compliance. Laceup Solutions systems help Organizations to have tight control of lots along the supply chain. If you want to learn more about Laceup Solutions, send us your information so we can schedule a meeting.

I hope this article has been helpful to you. I will continue to post information related to warehouse management, distribution practices and trends, and the economy in general. There is a lot of relevant information on our YouTube channel. Check this video on the subject.

Sorry, the comment form is closed at this time.