Solving Complex Inventory Issues with Technology

Inventory management is a critical aspect of supply chain operations. It can be a balancing act, where businesses strive to maintain enough stock to meet demand without overstocking, which ties up capital and incurs storage costs. As markets grow more complex, inventory challenges can intensify, affecting profitability and customer satisfaction. In this article, I explore some of the most complex inventory issues and discuss how technology can offer effective solutions.

Complex Inventory Issues

Seven warehouse processes get more complex as the company grows. They are:

Demand Forecasting and Variability: Predicting future demand is often one of the biggest challenges in inventory management. Inaccurate forecasts can lead to stockouts, overstocking, and missed sales opportunities. External factors like market trends, seasonality, and unexpected shifts in customer behavior further complicate demand forecasting.

Inventory Visibility Across Multiple Channels: With the rise of omnichannel retailing, companies need to track inventory across multiple sales channels—online stores, physical outlets, and third-party platforms. Ensuring real-time visibility and accurate stock counts across these channels can be daunting.

Stockouts and Overstocks: Balancing inventory to prevent stockouts and overstocks is a delicate challenge. Stockouts can result in lost sales and dissatisfied customers, while overstocks tie up working capital and increase warehousing costs.

Supply Chain Disruptions: Unexpected supply chain disruptions—such as delays, shortages of raw materials, or global events like pandemics—can severely impact inventory levels. These disruptions often cause sudden and unpredictable fluctuations in supply and demand.

Warehouse Space Optimization: As businesses expand, managing warehouse space efficiently becomes increasingly complex. Poor space management can lead to operational inefficiencies, higher costs, and longer order fulfillment times.

Product Expiration and Shelf Life: Managing inventory with expiration dates, such as perishable goods, pharmaceuticals, or cosmetics, adds another layer of complexity. Ensuring products are sold before they expire requires precise tracking and rotation systems.

SKU Proliferation: Businesses often face the proliferation of SKUs (Stock Keeping Units) as they expand their product lines. Managing a large number of SKUs can overwhelm traditional systems, leading to errors in the picking, packing, and replenishment processes.

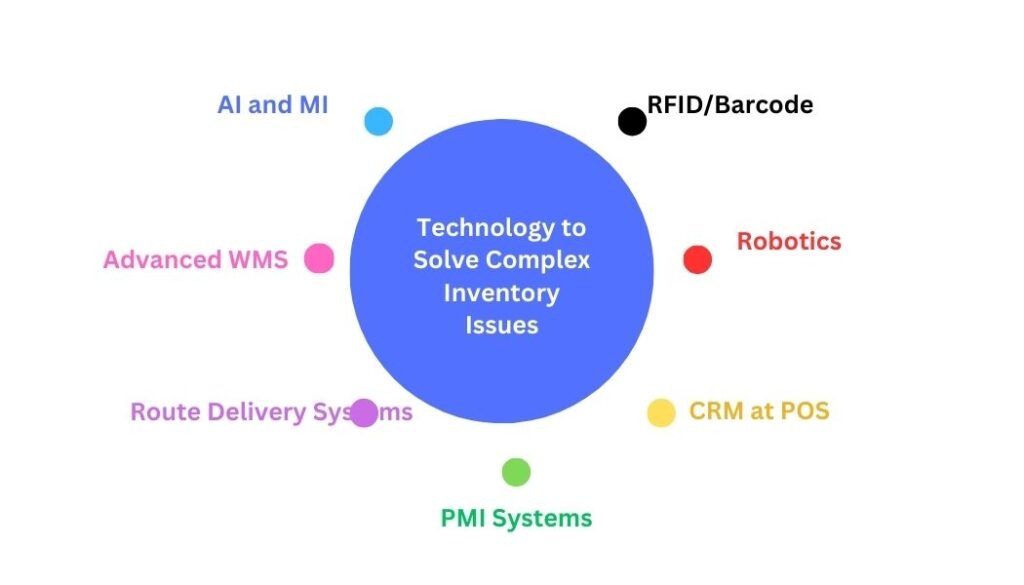

Technology Solutions for Complex Inventory Issues

As businesses grow, inventory management challenges intensify. The solution lies in integrating key technologies that address specific issues, ensuring seamless operations, improved accuracy, and enhanced customer satisfaction. Here are seven essential technologies that can tackle complex inventory problems:

RFID and Barcode Systems: RFID (Radio Frequency Identification) and barcode systems enable real-time tracking of products throughout the supply chain. These technologies allow for quick and accurate scanning of items, reducing manual errors and improving efficiency in inventory management. RFID tags provide an advantage over traditional barcodes by allowing multiple items to be scanned simultaneously, even without direct line of sight, which speeds up processes like stocktaking, product identification, and shipment verification.

AI-Powered Systems: AI-powered systems analyze historical data, market trends, and external factors to generate more accurate demand forecasts. These systems continuously learn and adapt, improving over time to minimize forecasting errors. When integrated with replenishment systems, AI can automatically trigger orders for restocking at the right time, reducing the risk of overstocking or running out of inventory. AI also helps optimize stock levels across different locations, enhancing overall supply chain efficiency.

Robotics and Conveyor Systems for Picking and Movement: Robotics and conveyor systems automate the picking and internal movement of products within the warehouse. These systems reduce human error, improve picking accuracy, and speed up order fulfillment. Autonomous mobile robots (AMRs) and automated guided vehicles (AGVs) can navigate warehouses to pick, transport, and deliver items to designated areas. Conveyor systems complement this by automating the movement of goods, streamlining processes, and enhancing productivity in large-scale operations.

Route Delivery Systems: Route delivery systems optimize delivery schedules and routes based on real-time data such as traffic conditions, delivery windows, and fuel consumption. These systems ensure that products are delivered on time while minimizing transportation costs. Route optimization software is particularly valuable for businesses with complex distribution networks or multiple delivery locations, enabling them to manage logistics more efficiently and enhance service levels.

CRM Systems at the Point of Sale (POS): CRM systems integrated with POS systems provide real-time visibility into stock levels, customer preferences, and sales data. This integration allows businesses to track inventory across multiple channels and locations, ensuring that stock data is always up to date. CRM at the POS also enables personalized customer interactions, loyalty programs, and targeted promotions, driving sales and improving customer satisfaction.

Advanced Warehouse Management Systems (WMS): An advanced WMS integrates all the aforementioned technologies—RFID, AI, robotics, and CRM—into a unified system that manages every aspect of warehouse operations. From lot tracking, picking, and packing to replenishment, inventory difference tracking, and order processing, an advanced and robust WMS provides complete control and visibility over inventory. Advanced WMS solutions can automate workflows, optimize space utilization, and enable faster, more accurate order fulfillment. By integrating with ERP systems, a WMS also ensures that inventory data is synchronized across all business functions, providing real-time insights for decision-making.

Product Information Management (PIM) Systems: As SKU proliferation increases, businesses can benefit from Product Information Management (PIM) systems that centralize and manage all product data. PIM systems allow businesses to maintain accurate product descriptions, dimensions, and inventory levels across all channels. By automating data synchronization, these systems reduce errors and streamline operations.

Conclusion

Managing complex inventory issues will continue be a growing problem, adopting the right technological tools can help businesses stay ahead of the curve and meet customer demands with greater agility and precision. Laceup warehouse software products can assist you in controlling demand forecasting, real-time inventory tracking, and automated replenishment, optimizing your inventory processes, and improving overall efficiency. If you want to learn more, give us your information to schedule a meeting.

I hope this article on complex inventory issues has been helpful to you. I will continue to post information related to warehouse management, distribution practices and trends, and the economy in general. Our channel has a lot of relevant information. Check out this video on a Demo of a Real WMS.

Sorry, the comment form is closed at this time.