Optimizing Warehouse Efficiency: An Overview of WMS Picking Strategies

Efficient picking processes are essential for maintaining a competitive edge. Warehouse Management Systems (WMS) offer a range of sophisticated picking strategies that optimize operations by reducing picking times, improving accuracy, and ultimately enhancing productivity. In this article, I explore several key WMS picking strategies and the factors that influence their effectiveness.

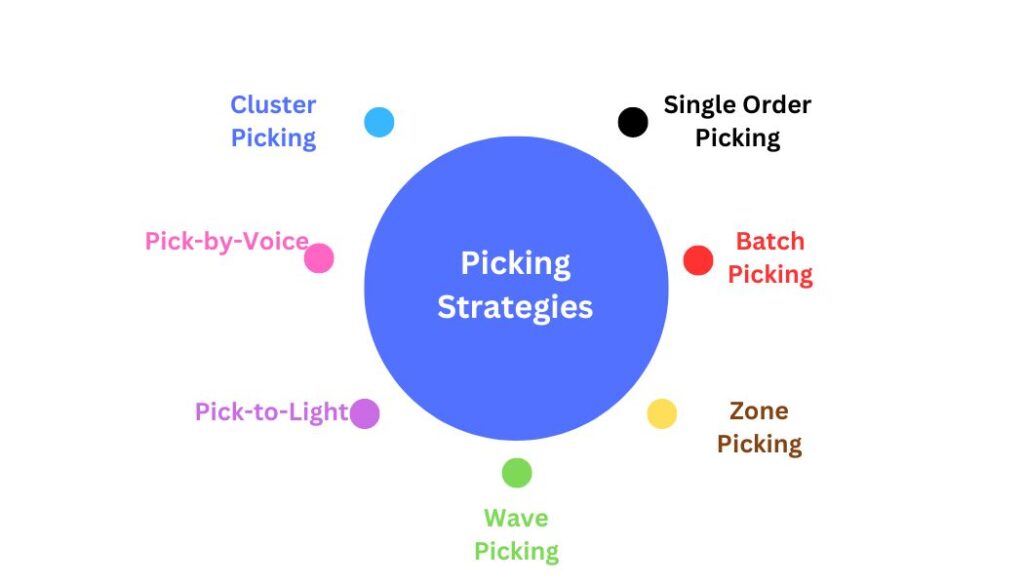

Summary of Picking Strategies

In a series of previous articles, we have explored picking methods and picking technologies. In this section I delve in seven different strategies to optimize picking. The figure summarizes them.

Single-Order Picking (Discrete Picking): Single-order or discrete picking is one of the most straightforward strategies. In this method, a picker handles one order at a time, retrieving all items for that specific order before moving to the next. This method is commonly used in smaller warehouses or operations with fewer orders, requiring minimal system complexity and ensuring high accuracy..

Pros:

- Simple to implement and manage.

- High picking accuracy.

- Easy to track individual orders.

Cons:

- Inefficient in larger warehouses or with high order volumes.

- Higher labor costs due to extensive walking and handling time.

Batch Picking: Batch picking is designed to increase efficiency by grouping multiple orders based on similar SKUs (stock-keeping units). A picker collects items for various orders in a single trip, reducing travel time across the warehouse. The orders are later sorted and packed individually.

Pros:

- Reduces travel time by picking up multiple orders at once.

- Increases picker productivity, especially when orders have overlapping items.

Cons:

- Requires additional sorting processes after picking.

- Less effective for orders with diverse product ranges.

Zone Picking: Zone picking involves dividing the warehouse into different zones, with each picker assigned to a specific area. Orders are divided into parts, and each picker is responsible for gathering the items within their designated zone. After all items are picked, the order is consolidated and packed.

Pros:

- Reduces picker travel distance, increasing efficiency.

- Allows for specialization within zones, improving speed and accuracy.

Cons:

- Requires effective coordination between zones.

- The process of consolidating items can be time-consuming and prone to errors.

Wave Picking: Wave picking combines elements of batch and zone picking, but it adds a scheduling layer. Orders are grouped into waves based on specific criteria such as delivery time, carrier schedules, or warehouse capacity. This ensures that pickers work on orders in a synchronized manner, maximizing efficiency while meeting shipping deadlines.

Pros:

- Ideal for warehouses with time-sensitive orders.

- Coordinates picking and shipping activities efficiently.

- Reduces congestion in the warehouse by staggering picking times.

Cons:

- Complex to manage without a robust WMS.

- Requires careful planning to ensure smooth execution.

Pick-to-Light: Pick-to-light is a highly efficient picking method that utilizes a system of lights and digital displays to guide pickers to the correct location and quantity for each item. Once the picker confirms the pick, the system automatically updates the WMS, reducing the need for manual input.

Pros:

- Extremely fast and accurate.

- Minimizes human error by providing visual cues.

Cons:

- Requires investment in hardware and system integration.

- Works best in high-volume operations with standardized SKU locations.

Pick-by-Voice: Pick-by-voice uses voice commands to direct pickers to the correct location and instruct them on how many units to pick. Pickers wear a headset and microphone, allowing for hands-free operation, which improves speed and reduces errors.

Pros:

- Hands-free, increasing speed and efficiency.

- High accuracy, especially in warehouses with complex layouts.

Cons:

- Requires training for effective use.

- Not suitable for noisy warehouse environments.

Cluster Picking: Cluster picking allows pickers to collect items for multiple orders in one trip by using a cart or tote system with separate compartments. Each compartment represents a different order, and the picker places items directly into their respective compartments.

Pros:

- Reduces travel time and increases efficiency by handling multiple orders in one pass.

- Ideal for e-commerce operations with small, frequent orders.

Cons:

- Potential for errors if items are placed in the wrong compartments.

- Requires precise tracking and coordination.

Choosing the Right Picking Strategies

The choice of WMS picking strategies depends on several factors:

- Order volume: High-volume operations benefit from batch, wave, or zone picking, while low-volume operations may prefer single-order or cluster picking.

- Warehouse size and layout: Larger warehouses often implement zone or wave picking to minimize travel distances, while smaller warehouses may not need complex strategies.

- Product characteristics: Warehouses handling small items or homogeneous products may find batch or cluster picking efficient, while larger or more varied items may require zone or discrete picking.

- Technology integration: Pick-to-light or pick-by-voice systems are effective for high-speed operations but require technological investments.

- Shipping requirements: Time-sensitive operations often rely on wave picking to ensure orders are processed in sync with shipping schedules.

Conclusion

Choosing the right WMS picking strategies can significantly impact a warehouse’s operational efficiency. Businesses can select the strategy that best fits their needs by considering factors like order volume, warehouse layout, and technology. Implementing these strategies with the support of a robust WMS ensures streamlined operations, improved productivity, and enhanced accuracy in the picking process.

Laceup Solutions’ suite of products will help you implement some of these strategies, ensuring that your DSD routes are efficient, cost-effective, and adaptable to real-world challenges. If you want to learn more, give us your information to schedule a meeting.

I hope this article has been helpful to you. I will continue to post information related to warehouse management, distribution practices and trends, and the economy in general. Our channel has a lot of relevant information. Check out this video on Metrics for Warehouse Productivity.

Sorry, the comment form is closed at this time.