Common Pitfalls in Warehouse Management and How to Avoid Them

Effective warehouse management is critical for ensuring smooth operations, cost control, and customer satisfaction. However, many warehouses face common pitfalls that can hinder efficiency and profitability. Understanding these challenges and implementing solutions can help businesses optimize their warehouse performance. In this article, I explain the most common pitfalls in warehouse management and actionable strategies to avoid them.

Most Common Warehouse management Pitfalls

Poor Inventory Management: Inaccurate inventory data, overstocking, stockouts, and misplaced items are major causes of inefficiencies. These issues lead to wasted resources, increased holding costs, and poor customer satisfaction.

Inefficient Warehouse Layout and Inadequate Space Utilization: As explained in our article about warehouse layout optimization, a poorly designed warehouse layout causes delays, increases labor costs, and reduces picking efficiency. Failing to maximize available warehouse space can lead to overcrowding, inefficient workflows, and difficulty locating products. For example, high-demand items placed far from dispatch zones can slow operations.

Lack of Standard Operating Procedures (SOPs): Without clear SOPs, workers may follow inconsistent processes, leading to errors, delays, and wasted time.

Manual Processes and Limited Automation: Relying on manual processes for inventory tracking, order fulfillment, and data entry increases the risk of errors and inefficiencies.

Neglecting Labor Management: Poor labor management can lead to underutilized resources, labor shortages, and high turnover rates.

Ignoring Technology Upgrades: Using outdated technology limits operational efficiency and makes it harder to compete in a fast-paced industry.

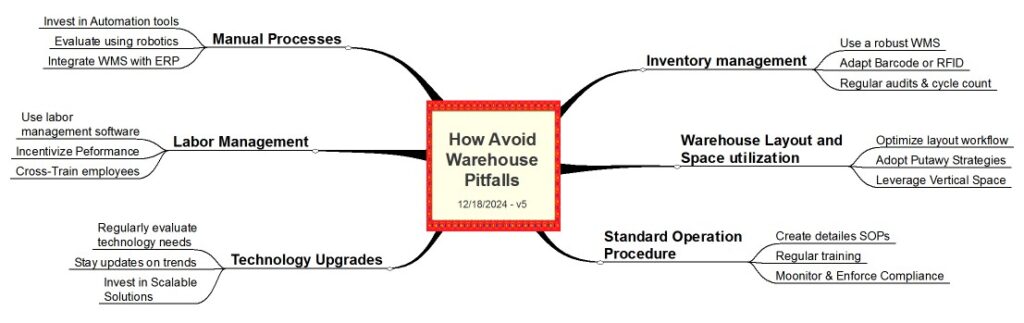

How to Avoid Warehouse management Pitfalls

The map below summarizes the most recommended strategies to avoid the pitfalls described.

Conclusion

Warehouse management is full of challenges, but avoiding these common pitfalls can significantly improve operational efficiency, reduce costs, and enhance customer satisfaction. Laceup Solutions can help you to avoid these pitfalls. If you want to learn more, give us your information to schedule a meeting.

I hope this article has been helpful to you. I will continue to post information related to warehouse management, distribution practices and trends, and the economy in general. Our channel has a lot of relevant information. Check out this video on how to optimize warehouse picking.

Sorry, the comment form is closed at this time.