How a Mismanaged Warehouse Can Bankrupt Your Company

Mismanagement in a warehouse doesn’t just result in inefficiencies; it can lead to spiraling costs, lost sales, and legal troubles. In extreme cases, it can drive a business into bankruptcy. In this article, we explore the most critical ways warehouse mismanagement can lead to financial disaster and how you can avoid these pitfalls.

Main Mismanaged warehouse issues

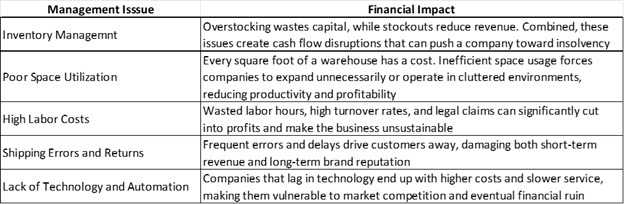

- Inventory Mismanagement Leads to Cash Flow Crises: Inventory is one of the most valuable assets of any company in the distribution business. When it is not appropriately managed, your company could face devastating financial consequences.

- Overstocking: Holding excessive inventory ties up cash and increases storage costs, obsolescence, and waste. Perishable goods can expire, and non-perishable items may become outdated or damaged before they are sold.

- Stockouts: On the other hand, failing to maintain sufficient stock results in lost sales, backorders, and dissatisfied customers who may take their business elsewhere.

- Inaccurate Inventory Data: Poor tracking systems lead to misplaced stock, ghost inventory (items showing in the system but not physically available), and costly emergency replenishment orders.

2. Poor Space Utilization Increases Operational Costs: A warehouse’s layout and storage strategy determines how efficiently goods are received, stored, and shipped. Mismanagement in this area can significantly drive-up costs.

- Wasted Space: Inefficient shelving and poor slotting strategies lead to underutilized warehouse space, requiring companies to unnecessarily rent or purchase additional facilities.

- Excessive Handling: If products are not stored logically, workers spend more time moving and searching for items, increasing labor costs and slowing down fulfillment.

3. High Labor Costs and Low Productivity Drain Profits: Labor is one of the highest expenses in warehouse management. If workforce operations are not optimized, companies end up paying more for less productivity.

- Untrained or Inefficient Staff: Without proper training and workflow optimization, employees make more mistakes, leading to shipping errors, returns, and customer dissatisfaction.

- Excessive Overtime: Poor scheduling and inefficient processes often require employees to work overtime, inflating labor costs.

- Workplace Safety Issues: A disorganized warehouse increases the likelihood of accidents, leading to costly workers’ compensation claims and potential lawsuits.

4. Shipping Errors and Returns Damage Reputation and Revenue: Customers expect accuracy and speed when ordering products. A warehouse plagued by mismanagement can struggle to meet these expectations, leading to customer loss.

- Picking and Packing Mistakes: Sending incorrect or damaged items results in costly returns and lost sales.

- Shipping Delays: Slow fulfillment leads to negative customer experiences and potential loss of contracts.

- Carrier Mistakes: If shipping processes are disorganized, freight costs may be higher than necessary, cutting margins.

5. Lack of Technology and Automation Causes Competitive Disadvantage: Many modern warehouses rely on warehouse management systems (WMS), barcode scanning, and automation to streamline operations. Companies that fail to implement these tools risk falling behind.

- Manual Processes Lead to Errors: Paper-based tracking and manual data entry increase the risk of mistakes and slow operations.

- Inability to Scale: Without automation, warehouses struggle to keep up with demand growth, limiting business expansion.

- Higher Operational Costs: Competitors using advanced technology will operate more efficiently, making it difficult for a mismanaged warehouse to remain profitable.

The Financial Impact of Mismanaged Warehouse

How to Prevent Mismanaged Warehouse

The good news is that warehouse mismanagement is preventable. Here are key strategies to ensure your warehouse remains an asset rather than a liability:

✔ Implement a Warehouse

Management System (WMS): Automating inventory tracking, order processing,

and reporting improves efficiency.

✔ Optimize Space and Layout: Regularly review

storage strategies to maximize space utilization.

✔ Train and Develop Staff: Warehouse

Management Software can keep trained your workforce. Invest in ongoing

training to improve efficiency and reduce errors.

✔ Use Data Analytics: Monitor key performance

indicators (KPIs) like inventory turnover, order accuracy, and labor

efficiency.

✔ Focus on Safety and Compliance: Conduct

regular safety audits and ensure compliance with all relevant regulations.

✔ Improve Supply Chain Visibility: Leverage

real-time tracking and analytics to avoid supply disruptions.

Conclusion

Warehouse mismanagement is not just an operational inconvenience but a financial risk that can drive a company into bankruptcy. From inventory chaos to excessive labor costs, every inefficiency in a warehouse eats into profitability. The best defense against these risks is proactive management, technology adoption, and a commitment to continuous improvement. Laceup integrated solutions provide companies with the tools to manage and optimize warehouse processes. Don’t hesitate to contact us for more information or to schedule a demo.

I hope this article on Mismanaged Warehouse and its effect on Distribution Fuel Costs has been helpful to you. I will continue to post information related to management, distribution practices and trends, and the economy in general. Our channel has a lot of relevant information. Check out this live demo of the best warehouse management system.

.

Sorry, the comment form is closed at this time.