WMS for Production Inventory Management in Metal Shops

Managing production inventory presents a different level of complexity compared to handling finished goods. In industries like metal fabrication, woodworking, plastics, and machining, inventory is not always measured in whole unit. Materials like sheets, rods, coils, or bars are often used in fractions. A WMS for production inventory must be equipped with specialized capabilities to support this level of precision, along with the standard features expected in any robust inventory system. In this article, I outline the critical features a WMS for production inventory must have to optimize inventory management in a metal shop and details how to manage quantities less than one.

Core Features of a WMS for Production Inventory

1. Real-Time Inventory Tracking: A WMS must provide real-time visibility into inventory levels, locations, and statuses across raw materials, work-in-progress (WIP), and finished goods. This means tracking full sheets, partially used materials, and scrap with up-to-date data to prevent production delays in a metal shop.

2. Support for Fractional Quantities: Metal shops frequently deal with partial materials, such as 0.75 meters of a rod or 0.4 of a steel sheet. The WMS must support flexible units of measure (UOM), including weight, length, area, or pieces, with seamless conversions. For example, cutting a 1-meter bar to 0.3 meters should automatically update the inventory to reflect the remaining 0.7 meters.

3. Lot and Serial Number Tracking Traceability is critical in metal shops, where materials must meet specific certifications (e.g., alloy grades). A WMS must track lot or serial numbers to ensure compliance, facilitate audits, and enable quick recalls if quality issues arise.

4. Bill of Materials (BOM) Integration Integration with BOMs ensures the WMS allocates the correct materials (e.g., specific metal grades or sizes) to production orders. This streamlines material planning and reduces errors in fulfilling production requirements.

5. Work-in-Progress (WIP) Management The WMS must track inventory as it moves through production stages, such as cutting, welding, or finishing. For instance, a sheet reduced to 0.5 of its original size after cutting should be logged as WIP or available inventory for future use.

6. Flexible Location Management Metal shops often store materials in diverse locations, from racks to outdoor yards for large items. The WMS should optimize storage assignments, support oversized items, and streamline picking routes to enhance efficiency.

7. Inventory Replenishment and Demand Forecasting: Automated reorder points and demand forecasting prevent stockouts of critical materials, such as specific alloys. o maintain production schedules, the WMS should account for lead times, especially for custom-order metals.

8. Integration with Production Systems: Seamless integration with Manufacturing Execution Systems (MES) or Enterprise Resource Planning (ERP) systems aligns inventory with production schedules. In a metal shop, this includes syncing with CNC machines or cutting plans to ensure material availability.

9. Scrap and Waste Management: The WMS must track scrap or offcuts (e.g., 0.2 meters of a rod) as reusable inventory or designate them for recycling. This feature minimizes waste and maximizes material utilization.

10. Barcode and RFID Support: Barcode or RFID scanning ensures accurate material identification and reduces errors in picking or inventory counts. In a metal shop, this is vital for quickly locating specific metal pieces or batches.

11. Reporting and Analytics: Robust reporting tools provide insights into inventory turnover, material usage, and waste. For example, analytics can identify excessive scrap from specific cutting processes, enabling process improvements.

12. User-Friendly Interface: A WMS should be intuitive for shop floor workers, with mobile or tablet support for real-time updates during production. This ensures accurate data entry, even in fast-paced environments.

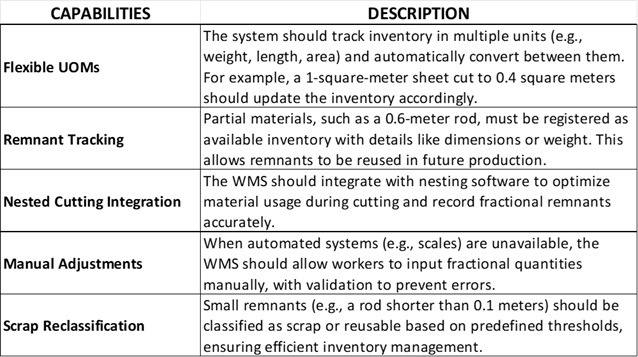

Managing Fractional Quantities in a WMS for Production Inventory Metal Shop

Handling quantities less than one is a common challenge in metal and wooden shops, where materials are cut or processed into smaller portions. A WMS must address this through the following capabilities:

Conclusion

A WMS tailored for production inventory management must combine real-time tracking, flexible UOM support, and integration with production systems to handle the complexities of materials like metals. The system minimizes waste, ensures traceability, and boosts operational efficiency by enabling precise management of fractional quantities and remnants. Implementing a WMS with these features empowers metal shops to streamline inventory processes and maintain a competitive edge in production. Laceup suit of integrated DSD, WMS, and Route systems can support your growth strategy. If you want to learn more about our solutions, contact us.

I hope this article on WMS for production Inventory has been helpful to you. I will continue to post information related to management, distribution practices and trends, and the economy in general. Our channel has a lot of relevant information. Check out this video on how to track raw material.

.

Sorry, the comment form is closed at this time.