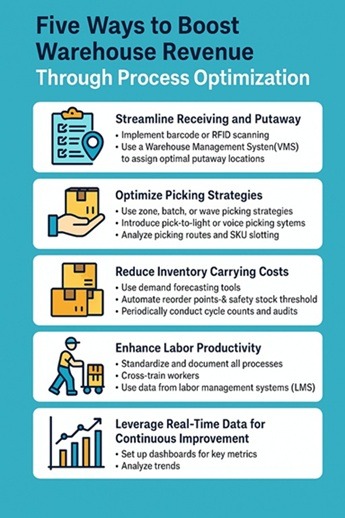

Boost Warehouse Revenue Through Process Optimization

Many distribution businesses are losing money due to inefficient warehouse operations. The encouraging news is that these losses don’t always require significant investments to fix. Often, minor yet strategic process adjustments can drive major gains in revenue. In this article, I outline some practical strategies to enhance performance and warehouse revenue optimization, as summarized below.

Increase Warehouse Revenue by Streamlining Receiving and Putaway

Delays in receiving and disorganized putaway routines can cause bottlenecks that ripple across the entire warehouse operation. By optimizing these initial steps in the supply chain, warehouses can enhance inventory availability and lower holding costs.

What to do: Implement barcode or RFID scanning to automate item identification, use a Warehouse Management System (WMS) to assign optimal putaway locations in real-time, and train receiving staff to check quality and reconcile shipments on the spot.

Impact: Faster inventory turnover and fewer errors translate directly into improved cash flow and reduced labor costs.

Improve Picking Routes and Strategies

Picking often represents the most significant portion of warehouse labor costs. Many warehouses have inefficient pick paths, with workers ending up at the far end of the facility, walking all the way back to drop off items, and wasting time and energy.

What to do: Depending on order profiles, use zone, batch, or wave picking strategies. Introduce pick-to-light or voice picking systems to guide workers more efficiently. Regularly analyze picking routes and SKU slotting to reduce travel time. Design picking routes that naturally lead to the front of the warehouse. Add shortcut paths near high-demand products so pickers don’t need to walk unnecessary distances. This adjustment can reduce travel time and increase Warehouse Revenue by up to 30%.

Maximize Truck Utilization

A common problem is that delivery trucks are only being loaded to about 60% of their capacity, which means nearly half of the available space is going unused. This results in doubled delivery expenses, as more trucks are needed to move the same amount of goods.

What to do: Adopt a load planning system that ensures pallets are configured to make full use of available truck space, ideally reaching at least 90% capacity. This reduces the number of trips and optimizes fuel and labor costs.

Use Sales Volume to Organize Inventory and increase Warehouse Revenue

Warehouse layouts often ignore product movement velocity. High-volume items might be placed far from the shipping area, slowing down fulfillment.

What to do: Identify your top 20% of products that account for most of your sales volume and relocate them closer to the front. Grouping fast-moving items together helps pickers process more orders faster, cutting pick time by 30% to 40%.

Eliminate Hidden Downtime

Warehouse workers frequently experience 1–2 hours of non-productive time each day that isn’t tracked as a break or task. This skews productivity metrics and reduces output.

What to do: Monitor and reduce this unaccounted time. Even small reductions in idle time can lead to a 12% to 20% increase in productivity, allowing you to manage growth without adding more labor.

Motivate With Performance-Based Incentives

Many operations treat all employees the same, regardless of performance. As a result, high achievers are not rewarded, and underperformers have no motivation to improve.

What to do: Develop an incentive program based on measurable metrics like pick accuracy, cases per hour, or completed stops. Daily scorecards and bonuses can boost productivity by about 22% and cut staff turnover by over a third.

Conclusion: A Clear Vision for the Future

Even implementing just one of these changes can significantly improve your operation. By addressing inefficiencies with targeted actions, companies can boost workforce efficiency by up to 30%, translating directly into higher revenue and more scalable growth. Laceup warehouse management solutions can help you to achieve these goals. Contact us to learn more about our solutions.

I hope this article about Warehouse Revenue optimization tips has been helpful to you. I will continue to post information related to management, distribution practices and trends, and the economy in general. Our channel has a lot of relevant information. Check out this recent video on “How To SIGNIFICANTLY Improve Revenue In your Warehouse Business”.

Sorry, the comment form is closed at this time.