Guide to Setting Up a WMS for Lot Traceability

Lot traceability is an essential practice for maintaining product integrity, ensuring quality, and meeting regulatory requirements. It becomes crucial in industries such as food and beverage, pharmaceuticals, or manufacturing, where products are batch-specific and the FDA requires specific lot traceability. With a Warehouse Management System (WMS), businesses can ensure proper tracking of lots from receiving to shipping, enhancing efficiency, minimizing errors, and preparing for audits or recalls. In this guide, I will walk through the steps needed to set up and implement a WMS for lot traceability. Whether you are refining an existing process or starting from scratch, these steps will help you get it right.

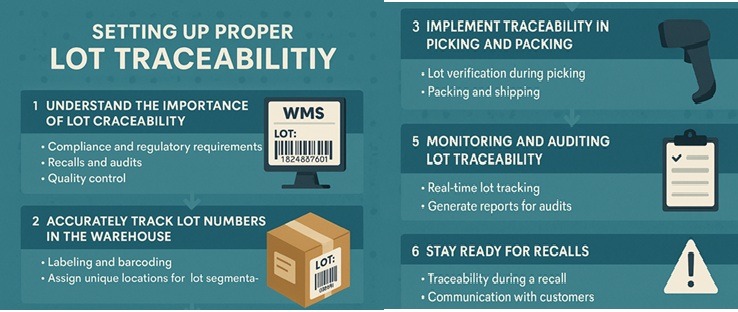

7 Step guide to set a WMS for lot traceability

Step 1: Understand the Importance of Lot Traceability

Before diving into system configurations of a WMS for lot traceability, it’s essential to understand why lot traceability matters:

- Compliance and Regulatory Requirements: For industries like food, healthcare, and chemicals, traceability is mandated by law to ensure safety and quality.

- Recalls and Audits: Proper lot tracking enables businesses to quickly identify affected batches in the event of product recalls and respond efficiently to audits.

- Quality Control: It helps track the origin, movement, and status of products within the warehouse, ensuring quality standards are met at every step.

Step 2: Set Up Your WMS to Handle Lot Numbers

Configure Lot Number Fields in Your WMS:

Ensure that your WMS allows the entry, tracking, and storage of lot numbers at

key touchpoints such as receiving, storage, picking, and shipping. Make sure

the system is set to capture all relevant details related to the lot:

- Lot ID

- Product/Batch number

- Expiration date (if applicable)

- Manufacturing or receipt date

- Quantity per lot

Enable Lot Tracking Across All Warehouse Operations:

You must configure your WMS to trace lots at every stage of the warehouse

process:

- Receiving: Ensure the system prompts for lot numbers when products are received and that each lot is associated with its corresponding product and quantity.

- Putaway: Lot numbers should be linked to specific locations in the warehouse.

- Picking: Ensure that when picking items for orders, the lot number is verified and tracked for accuracy.

Step 3: Accurately Track Lot Numbers in the Warehouse

Labeling and Barcoding:

Once a lot is received, label it with a barcode or RFID tag that contains the

lot number. This will ensure accuracy when picking, packing, and shipping the

products. Use barcode scanners to reduce human error when retrieving products,

ensuring that the lot number matches the items being handled.

Assign Unique Locations for Lot Segmentation:

To avoid mix-ups and ensure that lot numbers are easily accessible, assign

dedicated locations for each lot. For example, you could store products from

different lots in distinct shelving units or bins, making it easier to identify

and retrieve the correct lot when needed.

Step 4: Implement WMS for Lot Traceability in Picking and Packing

Lot Verification During Picking:

At the picking stage, train employees to verify the lot number before selecting

items for orders. In many WMS systems, this can be enforced by setting up

automatic prompts that ask workers to confirm the lot number before continuing.

Packing and Shipping:

When packing items for shipment, ensure that the correct lot number is recorded

for each product being shipped. This is crucial for ensuring that the lot is

correctly linked to the outgoing shipment. In case of an audit or recall, you

can easily identify which customers received products from a specific lot.

Step 5: Monitoring and Auditing Lot Traceability

Real-Time Lot Tracking:

Your WMS should be capable of real-time tracking of lot movements within the

warehouse. This means being able to pull up the current location, status, and

history of any lot within the system. It is helpful for tracking products that

are approaching their expiration date or need to be used before others.

Generate Reports for Audits:

Periodically generate reports that detail the movement of lots throughout the

warehouse. These reports should include:

- Lot receipt and shipment data

- Storage location history

- Expiration date status (if applicable)

- Order fulfillment details

This will help ensure compliance with regulations and prepare for audits, where a clear and accurate audit trail is essential.

Step 6: Stay Ready for Recalls

Traceability During a Recall:

If you ever need to conduct a recall, your WMS should

allow you to trace products by lot number. A reliable system should help you

identify which lots have been shipped to customers and who is at risk,

minimizing the time and effort required to take action.

Communication with Customers:

Your WMS should also integrate with customer service and other communication

systems to alert customers who received products from affected lots. This helps

streamline the recall process and maintain customer trust.

Step 7: Continuous Improvement

Conduct Regular Lot Audits:

Regular audits of lot traceability can help identify any gaps in the process.

This can involve checking physical locations against system records, verifying

the accuracy of lot labels, and ensuring proper documentation is maintained.

Train Your Staff:

Training your warehouse staff is crucial. Ensure they understand the importance

of a WMS for lot traceability and are well-versed in how to handle products at

each step of the process properly. This will reduce the chances of mistakes and

mix-ups.

Conclusion

Implementing proper WMS for lot traceability is a crucial process that can significantly improve operational efficiency and ensure compliance with industry standards. By following the steps outlined in this guide, your warehouse will be equipped to handle lot traceability seamlessly, reducing errors, and preparing you for audits or recalls. Laceup warehouse management solutions can help you achieve these goals. Contact us to learn more about our solutions.

I hope this article about WMS for lot traceability has been helpful to you. I will continue to post information related to management, distribution practices and trends, and the economy in general. Our channel has a lot of relevant information. Check out this recent video with a Cut Guide to Lot Traceability.

Sorry, the comment form is closed at this time.