Implementing AMRs in Your Warehouse: A Step-by-Step Guide

Autonomous Mobile Robots (AMRs) are becoming an essential tool for warehouses of all sizes aiming to increase efficiency, reduce labor costs, and enhance flexibility. However, introducing AMRs into warehouse operations requires careful planning and a phased approach to ensure a smooth integration. This guide walks you through the step-by-step process for successfully Implementing AMRs in a modern warehouse.

Step-By-Step Guide for Implementing AMRS

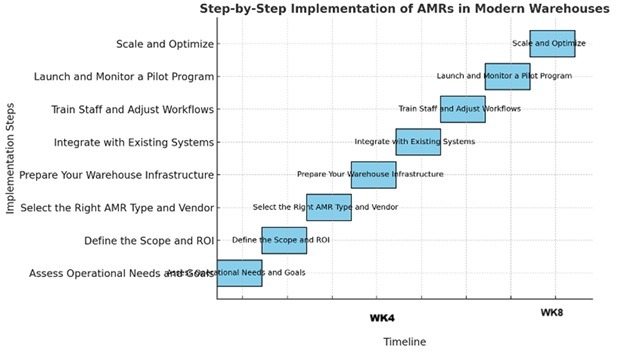

1. Assess Operational Needs and Goals

Before selecting an AMR solution, identify the specific operational challenges you aim to address.

- Are you struggling with labor shortages?

- Do you need to speed up picking or improve replenishment efficiency?

- Are you looking to reduce internal transportation costs?

Tip: Map current workflows and quantify inefficiencies. For example, if workers spend 40% of their shift walking between zones, AMRs can reduce travel time significantly.

2. Define the Scope and ROI

Determine the scale of AMR implementation:

- Start small with a pilot project in one area of the warehouse.

- Define Key Performance Indicators (KPIs)—e.g., picking speed, order accuracy, and labor hours saved.

- Estimate ROI based on reduced manual labor, improved throughput, and fewer errors.

Example: A 50,000 sq. ft. facility might deploy 5–10 AMRs initially to evaluate cost-effectiveness before scaling to 30 units.

3. Select the Right AMR Type and Vendor

Not all AMRs are created equal. Choose the solution that aligns with your operation’s needs:

- Tote-to-person AMRs for small goods picking.

- Pallet-moving AMRs for heavy load transportation.

- Sorting AMRs for high-volume parcel operations.

When selecting a vendor, consider:

- Software integration capabilities with your WMS or ERP.

- Flexibility for workflow changes.

- Support, maintenance, and scalability.

4. Prepare Your Warehouse Infrastructure

AMRs don’t require fixed infrastructure like AGVs, but they do need a conducive environment:

- Ensure clear pathways free of debris or obstructions.

- Install Wi-Fi coverage throughout operational zones.

- Define charging stations and battery swap protocols.

Pro Tip: Use floor markings and QR codes only if recommended by the AMR’s navigation system, since many modern AMRs use LiDAR and SLAM (Simultaneous Localization and Mapping).

5. Integrate with Existing Systems

For maximum efficiency, AMRs should integrate

with your Warehouse Management System (WMS), order processing

software, and inventory tracking tools.

Integration allows:

- Real-time task assignments.

- Dynamic route optimization.

- Automated order status updates.

6. Train Staff and Adjust Workflows

People and robots need to work together seamlessly:

- Train staff on AMR interaction—loading/unloading, troubleshooting, and safety protocols.

- Redesign workflows to incorporate AMRs without creating bottlenecks.

- Assign “AMR Champions” in each shift to monitor performance and resolve issues quickly.

7. Launch and Monitor a Pilot Program

Begin with a limited deployment to measure performance in a controlled environment.

- Track KPIs against baseline data.

- Collect feedback from operators.

- Identify areas for improvement before full rollout.

8. Scale and Optimize

Once the pilot is successful:

- Gradually increase the number of AMRs and operational zones covered.

- Adjust routes, tasks, and system parameters based on data insights.

- Continue periodic reviews to ensure the AMRs adapt to seasonal peaks or layout changes.

Benefits of Implementing AMRs Properly

- Labor Efficiency: Reduce non-value-added walking time.

- Scalability: Easily add more units as demand grows.

- Accuracy: Minimize human picking and transportation errors.

- Safety: Lower risk of accidents in repetitive transportation tasks.

Step-By-Step Diagram

Conclusion

Implementing AMRs in a warehouse is a strategic operational transformation. By following a structured step-by-step approach, you can ensure a smooth transition, minimize risks, and fully capture the efficiency gains that AMRs promise. Warehouses that take the time to plan, train, and integrate their AMRs effectively will be well-positioned to meet the demands of modern, high-speed distribution networks. Laceup warehouse management solutions can help you cope with the challenges associated with it. Contact us to learn more about our solutions.

I hope this article about Implementing AMRs in your warehouse, have been helpful. I will continue to post information related to management, distribution practices and trends, and the economy in general. Our channel has a lot of relevant information. Check out this video on Methods to Integrate Warehousing Software.

Sorry, the comment form is closed at this time.