Warehouse Execution Systems (WES): A Supply Chains Missing Link

Warehouse Execution Systems (WES) are software solution that sits between a Warehouse Management System (WMS) and a Warehouse Control System (WCS). It acts as a real-time orchestrator, dynamically managing and optimizing the flow of work, resources, and automation within a warehouse or distribution center. In this article, I explain the concept of a WMS, its relationship with a WMS, its benefits, and Challenges.

What are Warehouse Execution Systems?

A Warehouse Execution System (WES) is software that sits between a WMS (focused on inventory and order management) and a WCS (focused on equipment and automation control). WES combines the strengths of both, enabling real-time task orchestration, workload balancing, and process optimization.

Unlike a WMS, which plans “what” to do, Warehouse Execution Systems focuses on “how” and “when” to do it, ensuring work is released to the floor at the right time, in the right sequence, and with the right resources.

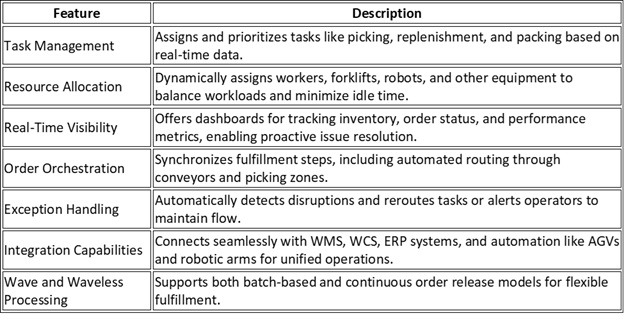

Key Components and Features of Warehouse Execution Systems

A robust WES includes a suite of features that enable precise control and optimization. Here’s a breakdown of some essential components:

These features allow WES to perform advanced analytics, such as predictive and prescriptive analysis, to forecast issues and suggest optimal solutions.

WES vs. WMS vs. WCS: A Clear Distinction

Understanding the difference between these three systems is crucial. While they all play a role in warehouse operations, they operate at different levels of the supply chain hierarchy.

Warehouse Management System (WMS): This is the “brain” of the warehouse. The WMS handles strategic, high-level planning and inventory management. It manages inventory, tracks orders from receipt to shipping, and provides overall labor and space management. It tells the WES what needs to be done.

Warehouse Control System (WCS): This is the “nervous system.” The WCS directly controls and communicates with the physical hardware, such as conveyors, sorters, and automated storage and retrieval systems (AS/RS). It ensures the equipment operates smoothly. The WCS takes commands from the WES and executes them.

Warehouse Execution System (WES): This is the “air traffic controller.” The WES bridges the gap between the WMS and WCS. It takes the plan from the WMS and translates it into real-time execution commands for both people and equipment, providing the intelligence needed to handle dynamic, complex operations and make real-time decisions that a WMS or WCS alone can’t. A Warehouse Execution System (WES) is a software solution that sits between a Warehouse Management System (WMS) and a Warehouse Control System (WCS). It acts as a real-time orchestrator, dynamically managing and optimizing the flow of work, resources, and automation within a warehouse or distribution center. It takes high-level directives from a WMS and translates them into actionable, real-time tasks for both human workers and automated equipment.

The Role of a WES in a Warehouse

Think of a WES as the air traffic controller for a warehouse. It takes the flight plan (the WMS’s overall strategy) and the individual airplanes (the WCS’s control of machines) and ensures every action is perfectly timed and coordinated to avoid collisions and maximize efficiency. Its primary goal is to optimize the execution of tasks in real-time, considering current conditions like order volume, inventory availability, and resource constraints. A WES handles various functions to achieve this, including:

Dynamic Task Management: It prioritizes and sequences tasks (e.g., picking, replenishment, put-away) based on real-time factors like order deadlines, worker availability, and proximity to items.

Resource Allocation: It intelligently assigns tasks to the most suitable resource, whether it’s a person, a forklift, an automated guided vehicle (AGV), or a robot, ensuring optimal utilization and workload balancing.

Order Fulfillment Optimization: The WES determines the most efficient picking and routing strategies, minimizing travel time and consolidating orders into a single pick path to increase productivity.

Real-time Visibility: It provides a live view of the status and location of inventory, orders, and resources, allowing managers to monitor performance and make informed decisions on the fly.

Benefits of a WES

Implementing a WES can significantly improve a warehouse’s efficiency and profitability. Key benefits include:

Increased Productivity and Efficiency: By dynamically prioritizing tasks and optimizing workflows, a WES can boost overall throughput and reduce idle time for both humans and machines.

Improved Order Accuracy: Real-time data and automated processes minimize human error during picking and packing, leading to a higher level of order accuracy and reduced returns.

Cost Reduction: A WES helps reduce operational costs by eliminating bottlenecks, optimizing labor resources, and minimizing the need for expensive system overhauls.

Enhanced Adaptability: A WES provides the flexibility to respond to real-time disruptions, such as a rush order or equipment failure, without manual intervention, keeping operations on track.

Conclusion

Warehouse Execution Systems represent a critical advancement in logistics technology, offering the intelligence and agility needed to thrive in today’s competitive landscape. By optimizing every aspect of warehouse operations, WES not only improves efficiency but also positions businesses for long-term success. For organizations grappling with complex fulfillment demands, investing in a WES could be the key to unlocking unprecedented operational excellence. LaceUp Solutions offers WMS that can be integrated with WES systems. Contact us if you want more information on our solutions.

I hope this article about Warehouse Execution Systems, have been helpful. I will continue to post information related to management, distribution practices and trends, and the economy in general. Our channel has a lot of relevant information. Check out this video how AI will realistically Help Your Company.

Sorry, the comment form is closed at this time.