Put-Away Strategies in High-Volume Warehouses to Maximize Speed, Accuracy, and Space Utilization

In previous articles we have explained the importance of the put away process to optimize warehouse receive movements. Inefficient put-away can lead to immediate congestion, delayed order fulfillment, and higher operational costs. For high-volume warehouses, processing thousands of items daily, adopting smart, data-driven strategies is key to maintaining a smooth and profitable operation. In this article, I explore advances put-away strategies for high-volume warehouses.

Understanding the Put-Away Process

The put-away process begins once goods arrive at the receiving dock and involves moving them to designated storage spots. The put-away process determines:

- How fast inventory becomes available for picking

- How efficiently space is utilized in racks, bins, and bulk locations

- How predictable material flow is for the entire warehouse

- How often teams need to relocate or re-slot inventory

- How quickly new employees get up to speed

As volumes increase, a warehouse’s ability to maintain order flow and productivity depends heavily on smart slotting and a disciplined, system-driven put-away process.

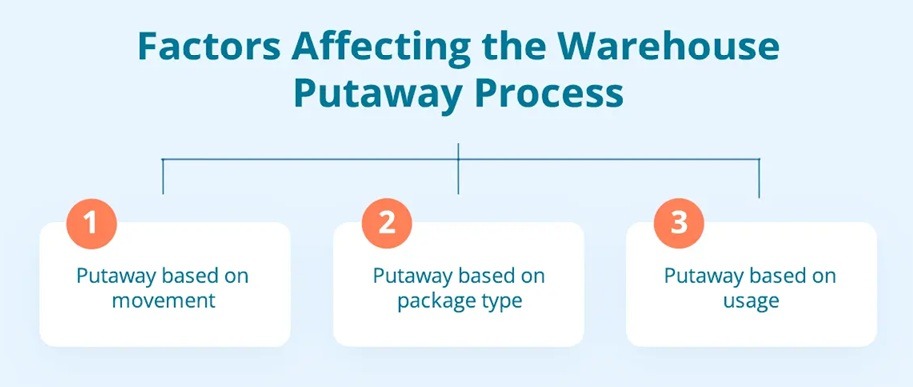

Types of Put-Away Strategies

Warehouses employ various put-away strategies to handle inventory, tailored to the characteristics and operational needs of each item. Common types include:

Fixed Location Put-Away: Items are assigned permanent storage spots based on product type, SKU, or destination. This is ideal for consistent inventory but lacks flexibility for seasonal changes.

Dynamic Put-Away: Locations adjust in real-time based on data like pick frequency and available space. High-volume items are placed closer to packing areas to cut travel time.

Directed Put-Away: Guided by WMS rules, workers scan items and follow system-directed paths. This balances predictability with adaptability.

Zone-Based Put-Away: The warehouse is divided into zones by product category or demand level (e.g., high-velocity zones near shipping). This streamlines operations by reducing worker movement.

Class-Based Put-Away: Uses ABC analysis to categorize items—A (high-demand) near access points, C (low-demand) in remote areas—for efficient space use.

Random Put-Away: Items are placed in the nearest available spot that meets the criteria, maximizing space in variable inventory scenarios.

Direct Put-Away: Bypasses staging, moving goods directly from receiving to storage, thereby speeding up the process for time-sensitive, high-volume operations.

These strategies can be combined; for instance, using fixed locations for staples and dynamic for seasonal goods.

Advanced Put-Away Strategies for High-Volume Warehouses

In high-volume settings, basic strategies evolve with technology to handle scale. Here are eight advanced approaches:

Dynamic Slotting: Adjusts slots based on real-time demand data, reducing travel and enhancing efficiency during peak periods.

Cross-docking: Transfers goods directly from inbound to outbound without storage, minimizing handling for perishables and reducing space requirements.

Automated Guided Vehicles (AGVs): Robots transport items to locations, lowering labor costs and errors while speeding operations.

Zone-Based Put-Away: Specializes zones for categories, streamlining processes and reducing travel.

Advanced WMS with Real-Time Integration: Provides instant instructions via RFID or barcodes, optimizing space utilization and retrieval efficiency.

AI-Powered Predictive Put-Away: Uses historical data and forecasts to predict optimal spots, making high-demand items accessible.

FIFO/LIFO Integration: Applies First-In-First-Out (FIFO) for perishables or Last-In-First-Out (LIFO) for other items, enhanced by WMS for improved management.

Vertical Put-Away with AS/RS: Robotic systems enable high-density vertical storage, maximizing space and throughput in large facilities.

These strategies leverage automation and data analytics to manage the chaos of high-volume inflows.

Leveraging Technology

In a high-volume setting, these strategies are impossible to execute effectively without the right technology:

Warehouse Management System (WMS): The core system that executes the logic (e.g., “put this SKU in location B3-12-A because it’s an A-item, and that bay is empty”).

Radio Frequency (RF) and Barcode Scanning: Ensures 100% accuracy in confirming the item and the storage location, preventing costly misplacements.

Material Handling Equipment (MHE) Automation: Utilizing conveyor systems, Automated Storage and Retrieval Systems (AS/RS), or autonomous mobile robots (AMRs) to perform the physical movement of goods, which is often faster and more consistent than human labor.

Conclusion

By embracing these strategies and the technology that supports them, high-volume warehouses can transform their receiving docks from potential bottlenecks into highly efficient, seamless parts of their overall fulfillment operations.

At LaceUp Solutions, we explore how technology transforms distribution, from warehouse management and route optimization to digital sales enablement. Subscribe to the LaceUp Blog for weekly insights on wholesale growth, innovation, and the future of logistics. For more information, please get in touch with us to learn about our solutions.

I hope this article about Put-Away Strategies have been helpful. I will continue to post information related to management, distribution practices and trends, and the economy in general. Our channel has a lot of relevant information. Check out this video on “What is Put-Away”.

Sorry, the comment form is closed at this time.