Reverse Logistics Transform Returns and Waste into Profits

Reverse logistics has traditionally been treated as a necessary evil, an operational burden driven by returns, damaged goods, warranty claims, and overstocks. But as margins tighten and sustainability becomes a competitive requirement, distributors and manufacturers need to rethink how to manage these processes. In this article, I explain how companies that redesign their reverse logistics processes to focus on recovery, refurbishment, resale, and recycling will unlock new revenue streams, reduce waste, and meet rising customer and retailer expectations for circular-economy practices.

What Is Reverse Logistics?

Reverse logistic refers to the processes involved in returning products from the end consumer back to the retailer, manufacturer, or another point in the supply chain. This includes managing returns, repairs, warranty claims, end-of-life recycling, and even failed deliveries. Unlike forward logistics, which focuses on getting products to customers efficiently, reverse logistic deals with the “backward” flow, aiming to recapture value from items that would otherwise be lost.

Refurbishment as a Revenue Generator

While returns are the most visible part of reverse logistics, refurbishment takes it a step further by transforming slightly used or defective items into sellable products. This involves repairing, cleaning, and testing goods to meet quality standards, often allowing them to be sold at a discount with warranties. For instance, an electronics company might fix a returned $100 device for just $15 in costs and resell it for $80-90, yielding margins of 15-25%, often higher than new product sales.

Apple stands out as a prime example, with its certified refurbished program offering pre-owned devices that undergo rigorous testing and come with full warranties. This not only recovers value but also taps into budget-conscious markets, turning potential waste into a high-margin business line.

Resale: Creating Secondary Markets With Strategic Purpose

Not everything needs complete refurbishment. Many returned items are unused, open-box, or simply have minor packaging damage. These items can be channeled into specific resale markets.

- Discount Channels: Utilizing outlet stores, third-party liquidation platforms, or dedicated “open-box” sections on a website.

- Secondary Geographies: Selling products that are being phased out in one primary market to a secondary market where demand is still strong.

Resale allows companies to recover a high percentage of the original cost quickly, improving cash flow and reducing inventory holding costs—a critical component of overall profitability.

Recycling: Monetizing Materials

For items that can’t be refurbished or resold, recycling recovers raw materials like plastics, metals, and glass, preventing landfill waste and complying with regulations such as the EU’s Extended Producer Responsibility laws. This process can be profitable by selling reclaimed materials back into production or to third parties. This isn’t about throwing it in the blue bin; it is about disassembly and component recovery.

- Harvesting High-Value Components: Pulling out circuit boards, memory chips, or specialized motors for use in other refurbishment processes.

- Raw Material Recovery: Extracting precious metals (gold, silver, palladium) from electronics or recycling high-grade plastics and aluminum.

By systematically recovering materials, a company can offset the costs of new raw material purchases (cost avoidance) or sell the recovered materials for a profit. Furthermore, it significantly boosts your sustainability goals, which is increasingly valuable to consumers.

Technology as the Backbone of Profitable Reverse Logistics

Without the right technology, reverse logistic becomes chaotic. With it, it becomes a measurable, profitable workflow. Key systems include:

- WMS with reverse workflows: receiving, grading, repair status, and recirculation

- RMA management tools: to automate authorizations, reasons codes, and claim tracking

- AI-driven inspection: photo-based grading and damage detection

- Analytics dashboards: recovery value, refurb cycle times, cost vs. resale value

When reverse logistic is digitized, operators can identify trends, reduce manual handling, and optimize recovery per unit.

Building a Profit-Centered Reverse Logistics Strategy

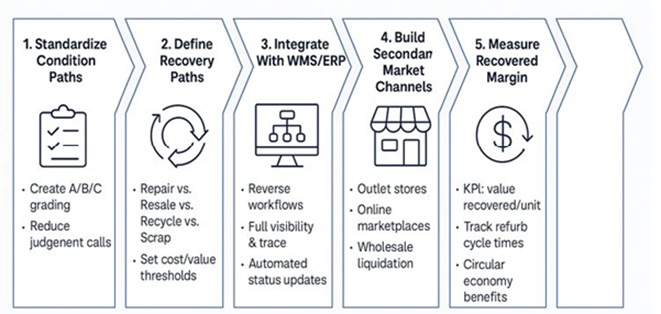

To transition reverse logistic from cost to profit, companies should:

Conclusion

Reverse logistic represents one of the most significant untapped opportunities in distribution and manufacturing. It combines operational efficiency, sustainability, and revenue generation into a single strategic function. By moving beyond the traditional view of returns as a burden and embracing refurbishment, resale, and recycling, companies can build a true profit center that improves margins, accelerates inventory cycles, and supports circular-economy goals.

At LaceUp Solutions, we explore how technology transforms distribution, from warehouse management and route optimization to digital sales enablement. Subscribe to the LaceUp Blog for weekly insights on wholesale growth, innovation, and the future of logistics. For more information, please get in touch with us to learn about our solutions.

I hope this article have been helpful. I will continue to post information related to management, distribution practices and trends, and the economy in general. Our channel has a lot of relevant information. Check out this video on how to reduce turnover in your warehouse.

Sorry, the comment form is closed at this time.