Navigating Logistics Maze: Cost-Benefit Analysis of In-House vs. Outsourced Logistic Operation

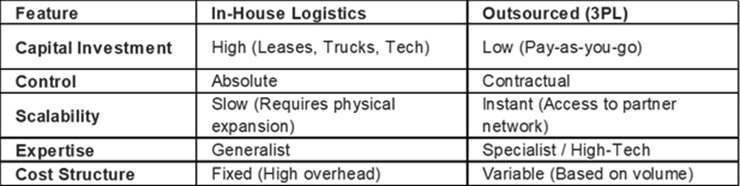

Efficient logistics management is crucial for maintaining competitive edges, ensuring customer satisfaction, and optimizing operational costs. Companies often face the pivotal decision between handling in-house or outsourced logistic operation to third-party logistics (3PL) providers. This choice impacts everything from warehousing and delivery to specialized tasks like reconciliation. In this article, I make a comprehensive cost-benefit analysis of in-house versus outsourced logistics, followed by practical guidance on when to outsource specific components such as warehousing, delivery, and reconciliation.

Understanding In-House Logistics

In-house logistics involves managing all supply chain activities internally, including inventory storage, transportation, and order fulfillment. This model offers unparalleled control over operations, allowing companies to customize processes to their exact needs and maintain direct oversight of quality and security. However, it comes with high upfront and ongoing costs. Capital expenditures (CapEx) for infrastructure such as warehouses, vehicles, and technology can be substantial, often requiring significant investments in real estate, equipment, and personnel. Additionally, fixed costs such as salaries, maintenance, and utilities remain constant regardless of order volume, making it less adaptable to demand fluctuations.

Benefits include faster decision-making, better alignment with company culture, and potential long-term savings if volumes are consistently high. For instance, businesses with predictable, large-scale operations might find in-house setups more economical over time, as they avoid the markup fees associated with external providers.

The Appeal of Outsourced Logistic

Outsourced logistic shifts responsibilities to specialized 3PL providers, converting fixed costs into variable operational expenditures (OpEx). This model is particularly cost-effective for growing businesses, as it eliminates the need for massive initial investments and allows scaling without proportional increases in costs. Key benefits include access to advanced technology, global networks, and expertise that might be unaffordable in-house, leading to improved efficiency and reduced shipping times. On the cost side, outsourcing can lower overall expenses by leveraging economies of scale, as 3PLs negotiate better rates with carriers and suppliers. A break-even analysis often reveals that for mid-sized operations, outsourcing becomes profitable once order volumes exceed a certain threshold, avoiding the “cost of failure” in specialized areas like cold storage. However, drawbacks include potential loss of control, dependency on the provider’s reliability, and hidden fees for customization or peak-season surcharges.

When to Outsource Warehousing

Warehousing is a core logistics function involving inventory storage, management, and distribution. Deciding to outsource it depends on your business’s growth stage, space constraints, and strategic focus. Outsource warehousing when your in-house facilities are nearing capacity or during periods of rapid expansion, as building new infrastructure can be prohibitively expensive and time-consuming. If revenue is declining or seasonal, outsourcing provides variable costs tied to usage, avoiding fixed overheads. Key indicators include rising maintenance costs, inefficient space utilization, or the need for specialized storage (e.g., temperature-controlled environments). Businesses outsourcing often gain access to strategic locations, enhancing delivery speeds and customer satisfaction. However, retain in-house if you handle sensitive or proprietary goods requiring tight security.

A simple checklist: If you’re spending more on underutilized space or lacking advanced inventory tech, outsourcing can cut costs by up to 25% while boosting efficiency.

When to Outsource Delivery

Delivery, encompassing transportation and last-mile logistics, is often the most visible part of the supply chain. Outsourcing it can transform fixed fleet costs into pay-per-use models. Consider outsourcing delivery when your in-house team is overwhelmed, leading to late shipments or escalating fuel and maintenance expenses. Signs include unpredictable costs, missed delivery windows, or the inability to meet growing demand without hiring more staff. For e-commerce or retail, if orders surge seasonally, 3PLs offer scalable solutions, such as same-day delivery options, that in-house fleets might not afford.

Outsourcing is particularly beneficial for companies expanding geographically, as providers leverage established networks for better rates and coverage. If your business lacks real-time tracking tech or struggles with regulatory compliance, it’s time to delegate. Keep it in-house for hyper-local operations or when brand-specific delivery experiences are essential.

When to Outsource Reconciliation

Reconciliation in logistics typically refers to verifying invoices, freight bills, and inventory against actual transactions to ensure accuracy and prevent overpayments. This back-office function can be resource-intensive. Outsource reconciliation when your internal team is bogged down by manual processes, leading to errors or delays in financial reporting. It is advisable if you are dealing with high volumes of transactions or complex carrier contracts, where specialized software and expertise can identify discrepancies more efficiently. For freight businesses, outsourcing bank or freight bill reconciliation improves cash flow management and reduces fraud risks without the need for in-house accountants.

Indicators include rising administrative costs, frequent billing disputes, or a lack of real-time visibility into expenses. 3PLs or BPO firms offer automated tools that streamline this, often saving 15-20% on logistics spend through better auditing. Retain in-house if data sensitivity is a concern or for small-scale operations where costs don’t justify external help.

Decision Matrix at a Glance to Outsource Logistic Operation

Conclusion

The decision between in-house and outsourced logistic hinges on your business’s size, growth trajectory, and core strengths. A thorough cost-benefit analysis, factoring in tangible expenses and intangible benefits like scalability, can reveal the optimal path. Outsourcing warehousing, delivery, or reconciliation makes sense when internal resources are strained, costs are unpredictable, or expertise is lacking, allowing you to focus on innovation and customer service. Start with a pilot program with a reputable 3PL to test the waters, and regularly review performance metrics to ensure alignment with your goals. By strategically outsourcing, businesses can achieve greater agility in an ever-evolving market.

At LaceUp Solutions, we explore how technology transforms distribution, from warehouse management and route optimization to digital sales enablement. Subscribe to the LaceUp Blog for weekly insights on wholesale growth, innovation, and the future of logistics. For more information, please get in touch with us to learn about our solutions.

I hope this article about outsourced logistic operations have been helpful. I will continue to post information related to management, distribution practices and trends, and the economy in general. Our channel has a lot of relevant information. Check out this video on Starting A Wholesale Distribution Business.

Sorry, the comment form is closed at this time.