A Case Study of WMS-TMS-DSD Integration

In today’s fast-paced and competitive business landscape, distributors and wholesalers are constantly seeking ways to optimize their operations and gain a competitive edge. One area that holds immense potential for improvement is supply chain management. By integrating key systems like Warehouse Management Systems (WMS), Transportation Management Systems (TMS), and Direct Store Delivery (DSD) solutions, businesses can unlock significant efficiencies and drive remarkable results. In this article, I delve into a successful case study of WMS-TMS-DSD Integration, highlighting the challenges faced, the solutions implemented, and the impressive outcomes achieved.

The Challenge: A Disconnected Supply Chain

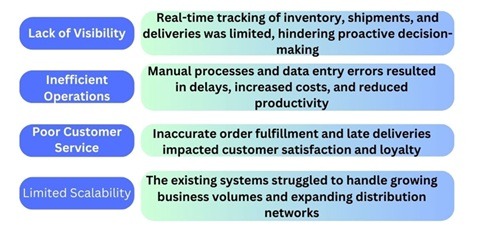

The company in question, a leading food and beverage distributor, faced numerous challenges due to its disparate systems. Their WMS, TMS, and DSD solutions operated in silos, leading to:

The Solution: A Seamless WMS-TMS-DSD Integration

To address these challenges, the company embarked on a comprehensive WMS-TMS-DSD integration project. This involved:

Selecting the Right Technology: Choosing compatible and scalable solutions that could seamlessly integrate with each other.

Data Mapping and Migration: Ensuring accurate and consistent data flow between the systems.

Process Optimization: Streamlining workflows and eliminating redundancies to maximize efficiency.

Training and Change Management: Equipping employees with the necessary skills and knowledge to utilize the integrated systems effectively.

The Results: A Transformation in Efficiency

The successful WMS-TMS-DSD integration systems yielded remarkable results for the company:

Enhanced Visibility: Real-time insights into inventory levels, shipment tracking, and delivery status empowered proactive decision-making and improved responsiveness to customer demands.

Improved Operational Efficiency: Automating key processes, such as order processing, route planning, and delivery confirmation, reduced manual errors, accelerated operations, and lowered costs.

Elevated Customer Service: Accurate order fulfillment, timely deliveries, and proactive communication enhanced customer satisfaction and strengthened relationships.

Increased Scalability: The integrated systems provided the flexibility and scalability to support business growth and expansion into new markets.

Key Takeaways WMS-TMS-DSD Integration Projects

For businesses considering similar integration projects, here are some key takeaways:

Thorough Planning: Define clear objectives, assess current systems, and select the right technology partners.

Data Integrity: Ensure accurate and consistent data across all systems to avoid errors and miscommunication.

Change Management: Prepare employees for the transition and provide adequate training to ensure smooth adoption.

Continuous Improvement: Regularly evaluate the integrated systems and identify areas for further optimization.

Conclusion

This case study demonstrates how businesses can leverage technology to streamline logistics and enhance overall performance. Companies looking to scale their distribution networks should consider a similar approach to drive efficiency, cost savings, and customer satisfaction. LaceUp’s solutions provide a robust platform for distribution companies to seamlessly integrate different systems, allowing you to monitor logistics costs closely. If you want to learn more about LaceUp’s solutions, give us your information to schedule a meeting.

I hope this article on WMS-TMS-DSD Integration has been helpful to you. I will continue to post information related to warehouse management, distribution practices and trends, and the economy in general. Our channel has a lot of relevant information. Check out this video of an In-Depth WMS Walkthrough.

Sorry, the comment form is closed at this time.