Bin inventory replenishment: What it is and its importance

Bin inventory replenishment is a warehouse’s critical process that ensures the continuous flow of goods and helps businesses maintain optimal inventory levels. In this article, I will discuss what bin replenishment is, how to do it, and why it is essential for warehouses to implement replenishment strategies.

What is bin inventory replenishment?

In general terms, replenishment is the process of adding more stock to replace what has been sold. Bin inventory replacement is the process of moving a pallet from a back stock or overstock location into a picking bin or slide. There are two types of replenishments: one for items that rotate frequently, which need to be replenished with full pallets, and another for items that don’t rotate as much, which require replenishing picking slides. The process of rotating a pallet involves taking it from the overstock bin to the floor, removing the necessary cases, moving them to the slide, and placing the pallet back above.

How to do inventory replenishment?

There are two primary methods of bin replenishment: manual and automated. The manual method involves physically checking each bin and recording the inventory levels, while the automated method utilizes a Warehouse Management System (WMS) to track inventory levels and generate replenishment orders.

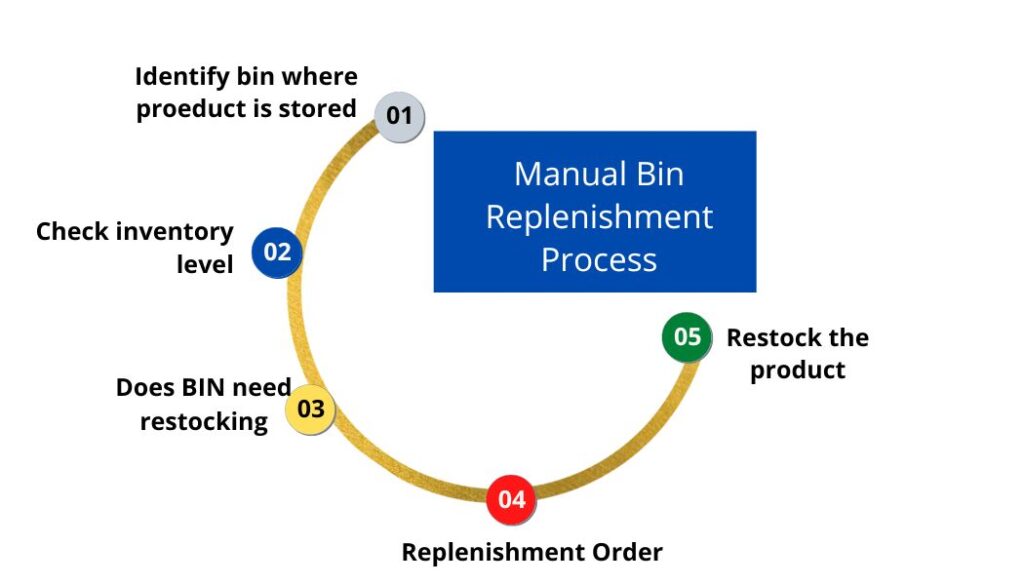

Manual Replenishment: The figure below shows the steps associated to manual replenishment.

Automated Replenishment: To perform automated bin inventory replenishment using a WMS, you need to follow these steps:

- Set up your WMS to track inventory levels for each bin or location in your warehouse.

- Set minimum stock levels for each item.

- Configure the WMS to generate replenishment orders automatically when inventory levels fall below the minimum stock level.

- Review and approve the replenishment orders generated by the WMS.

- Restock the items in the appropriate bins.

Benefits of bin inventory replenishment

Effective replenishment is critical for businesses to maintain optimal inventory levels and meet customer demand. Here are some reasons why replenishment is important:

- Prevent Stockouts: Replenishment ensures that there is always enough stock available to fulfill customer orders. This reduces the risk of stockouts, which damages the business’s reputation and result in lost sales.

- Reduce Overstocking: Effective replenishment strategies can help businesses avoid overstocking, which ties up working capital and can lead to higher storage costs and increased risk of product obsolescence.

- Improve Efficiency: By automating the replenishment process, businesses can achieve greater efficiency and accuracy, reducing the risk of errors and improving productivity.

- Optimize Inventory Levels: Replenishment helps businesses maintain optimal inventory levels, minimizing the risk of excess inventory and reducing the need for costly expedited shipping.

I hope this article has been helpful to you. I will continue to post information related to warehouse management, distribution practices and trends, and the economy in general. If you are interested in this article or want to learn more about Laceup Solutions, please subscribe to stay updated on future articles.

There is a lot of relevant information on our channel. Check out this video about replenishment.

Sorry, the comment form is closed at this time.