Complex Inventory Issues Solved with Technology

Inventory accuracy is already difficult in a high-velocity distribution operation. But when your operation involves mixed pallets, catch-weight products, or variable pack sizes, traditional inventory logic breaks down fast. These are daily realities in industries such as food distribution, protein, produce, dairy, beverages, chemicals, and building materials. And they cannot be solved with spreadsheets, paper adjustments, or basic inventory systems. In this article, I analyze modern warehouse and distribution technology specifically designed to handle these complex inventory issues.

What are the Most Common Complex Inventory Issues

Most legacy inventory systems assume a simple model: One SKU = one unit of measure. one pallet = one SKU, and One quantity = one count. Real operations are messier; common complex inventory issues include:

- Multiple SKUs on the same pallet

- Products are sold by weight, but stored and shipped by units

- Cases with varying quantities or weights

- Different sales, shipping, and financial units for the same product

When systems can’t model this reality, teams compensate manually, creating inventory drift, reconciliation nightmares, and financial exposure.

Complex Inventory Issues: Mixed Pallets and Pallet Reconciliation

Mixed pallets (or mixed-SKU/mixed-case pallets) contain multiple different products, sizes, and shapes, making manual verification, loading, and unloading slow, error-prone, and risky for product damage. Mixed pallets occur when picking for route-based or store-specific orders, consolidating slow movers with fast movers, and repacking or cross-docking operations. The problem is not physical handling; it is inventory visibility. A modern WMS solves this by assigning unique pallet or LPN IDs, tracking pallet contents at the SKU and lot level, and updating inventory in real time during picking and consolidation. Advanced systems allow::

- One pallet → many SKUs

- Partial pallet movements

- Real-time verification via barcode scanning

Result: Mixed pallets become auditable, traceable assets—not inventory black holes.

Catch Weight Management

Catch weight refers to products (common in the food and beverage industry like meat, seafood, and cheese) that are sold by the piece or case but priced by their actual, variable weight. This requires managing two units of measure, which is complex for standard inventory systems. Catch weight applies when products vary in weight per unit (meat, cheese, seafood), customers buy by pounds or kilos, or warehouses receive, store, and ship cases or pieces. Catch-weight-enabled systems support dual units of measure (e.g., cases + pounds), weight capture at receiving, picking, or shipping, and variable-weight barcodes or scale integrations. A proper implementation ensures:

- Inventory decrements match the actual shipped weight

- Sales, inventory, and accounting stay aligned

- Margin erosion becomes visible instead of hidden

Result: Weight variability becomes manageable and measurable.

Complex Inventory Issues: Variable Packs and Inventory Reconciliation

Variable packs (or multi-batch license plates) often involve a single pallet or container having the same SKU but from multiple different batches, production dates, or serial numbers, making inventory picks and record-keeping difficult. Variable packs appear when cases are assembled manually, promotions change pack composition, or suppliers ship inconsistent quantities. Modern systems handle variable packs by defining expected ranges rather than fixed quantities, capturing actual quantities at pack or pick time, and maintaining pack composition history per order. Advanced WMS/DSD platforms support::

- Flexible pack definitions

- Real-time pack validation

- Exception workflows when packs differ from standards

Result: Variability is captured at the source instead of “fixed” later.

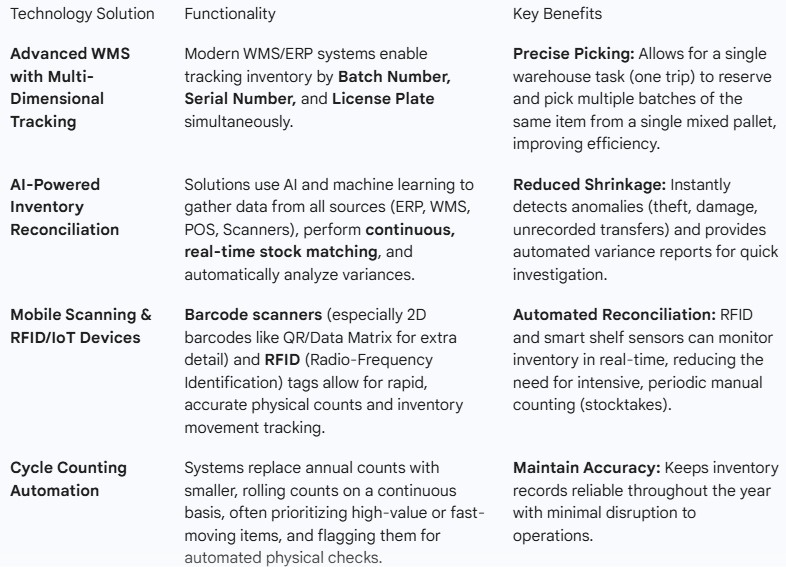

What to Look for in a Technology Stack That Can Handle Complexity

If your operation deals with mixed pallets, catch weight, or variable packs, your system must support:

- Pallet/LPN-level traceability

- Multiple units of measure per SKU

- Weight capture and audit trails

- Real-time inventory updates

- Lot, expiration, and compliance tracking

- Tight integration between warehouse, routing, and accounting

Without these, growth will only magnify existing problems.

Conclusion

Mixed pallets, catch weight, and variable packs are not operational flaws, they are business realities. The issue is whether your systems acknowledge that reality or fight it. Technology doesn’t simplify your products. It simplifies your control over them.

At LaceUp Solutions, we explore how technology transforms distribution, from warehouse management and route optimization to digital sales enablement. Subscribe to the LaceUp Blog for weekly insights on wholesale growth, innovation, and the future of logistics. For more information, please get in touch with us to learn about our solutions.

I hope this article on Complex Inventory Issues have been helpful. I will continue to post information related to management, distribution practices and trends, and the economy in general. Our channel has a lot of relevant information. Check out this video on “Different Bin Location Types In your Warehouse”.

Sorry, the comment form is closed at this time.