Cross-Docking: Streamlining Warehouse Operations

Efficient warehouse operations are essential for businesses to meet the demands of modern-day consumers. One key strategy that has revolutionized the logistics industry is cross-docking. This technique enables companies to streamline their warehouse operations, resulting in faster order fulfillment and improved customer satisfaction. In this article, I explore the concept of cross-docking, its benefits, and how it can optimize warehouse processes.

Understanding Cross-Docking

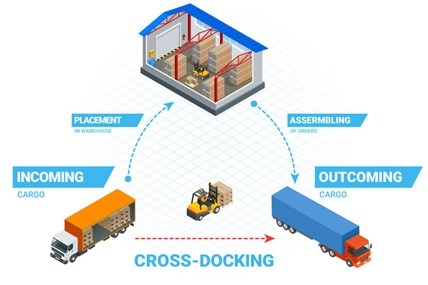

Cross docking is a logistics method that involves unloading inbound products from vendors, swiftly transferring them across the warehouse dock, and staging them for immediate shipment. Similar to a relay race, cross docking eliminates the need for storage and enables seamless movement of goods from vendors to delivery trucks.

Importance and Benefits of Cross-Docking

Cross-docking offers several key benefits that revolutionize warehouse operations and enhance supply chain efficiency. Let’s explore four primary advantages that businesses can gain from implementing cross-docking:

Minimize carrying costs: Cross-dock eliminates the need for storing products, thus reducing inventory carrying costs. Without the complex processes associated with inventory management, employees can focus on simpler and more productive tasks.

Enhanced employee productivity: By simplifying warehouse tasks, cross-dock significantly increases employee productivity. With a streamlined process of moving products from inbound to outbound, employees can handle tasks more efficiently

Warehouse space optimization: Cross-dock optimizes warehouse space utilization by focusing on the 20% of inventory that generates 80% of deliveries. By eliminating the need for extensive storage, businesses can operate with reduced space requirements and save costs.

Fill Orders Quickly: Another significant benefit of cross-dock is the ability to fill orders rapidly. With cross-docking, products can be received from suppliers, quickly sorted, and promptly loaded onto outbound vehicles for immediate delivery. This efficient process minimizes order fulfillment time, ensuring that customer orders are processed and shipped swiftly. Businesses can meet customer demands more effectively, improve order accuracy, and enhance customer satisfaction.

Implementing Cross-Docking

To successfully implement cross docking, a customer needs to undertake several key steps:

- Evaluate Warehouse Operations: Assess the current warehouse layout, processes, and inventory management systems. Identify areas that can benefit from cross-docking and determine the potential impact on operational efficiency.

- Vendor Selection and Collaboration: Identify vendors who can support the cross-docking process. Evaluate their capabilities, proximity to the warehouse, and willingness to participate in cross-docking operations. Establish strong communication channels and collaborate closely with selected vendors to ensure timely delivery and seamless coordination.

- Vendor Lead Times: Work with vendors to establish short lead times for order fulfillment. This ensures that the vendor can deliver products in a time frame that allows for immediate cross-docking and shipment.

- Product Allocation: Use a system of record, such as a warehouse management system (WMS), to link each product to its corresponding order and establish clear allocation records. This ensures accurate tracking and redirection of products during the cross-docking process.

- Sorting and Staging Areas: Create designated sorting and staging areas within the warehouse. These areas allow for efficient sorting and breakdown of inbound shipments and the preparation of outbound shipments.

- Employee Training and Education: Provide comprehensive training to warehouse staff on the principles and practices of cross-docking.

- Continuous Monitoring and Optimization: Regularly monitor and assess the effectiveness of cross-docking operations. Analyze key performance indicators (KPIs) such as order fulfillment time, inventory turnover, and cost savings. Identify areas for improvement and implement necessary adjustments to optimize the cross-docking workflow further.

Case Study: The Power of Cross Docking

There are several real case studies that illustrate the successful implementation of cross docking. One such case study involves Walmart. By utilizing cross-dock, Walmart was able to streamline its distribution process and significantly reduce inventory holding costs.

In the case of Walmart, products are received from suppliers at their distribution centers. Instead of being stored, these products are immediately sorted and redirected to outbound trucks based on their destinations. This approach enables Walmart to bypass the traditional warehousing process and expedite the delivery of goods to its stores.

The benefits of cross-docking for Walmart were remarkable. It allowed the company to minimize inventory levels, reduce handling and storage costs, and improve the speed of order fulfillment. By optimizing their supply chain through cross-dock, Walmart achieved greater efficiency, reduced lead times, and increased customer satisfaction.

I hope this article cross-docking has been helpful to you. I will continue to post information related to warehouse management, distribution practices and trends, and the economy in general. If you want to know how Laceup’s solution can help you to successfully implement cross docking, click the link below to schedule an exploratory meeting.

There is a lot of relevant information on our channel. Check out this video on the subject.

Sorry, the comment form is closed at this time.