Digital Twins in Distribution: Simulating Warehouse, Fleet, & Delivery Performance

As distribution operations become more complex and data-driven, Digital Twins are emerging as a transformative technology for simulating, optimizing, and managing every moving part of the supply chain. By creating a virtual replica of physical assets and processes, like warehouses, delivery fleets, and logistics networks, companies can predict outcomes, test strategies, and make smarter, faster decisions. In this article, I explain the benefits and challenges of Digital Twins in Distribution.

What Are a Digital Twins in Distribution?

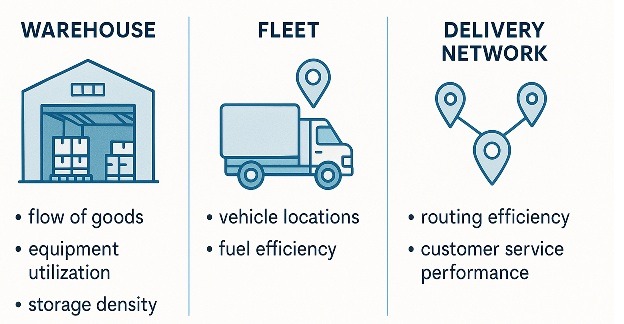

A Digital Twin is a real-time digital model of a physical system that mirrors its behavior using live data, sensors, and analytics. In distribution, it comprises following processes:

The twin continuously synchronizes with real-world operations through IoT devices, WMS (Warehouse Management Systems), TMS (Transportation Management Systems), and ERP platforms, creating a unified, intelligent and integrated model of the entire supply chain.

Digital Twins in Distribution: Simulating Warehouse Performance

In warehouse environments, Digital Twins help visualize and optimize the internal flow of materials and labor.

Key application

Layout Optimization: Testing different rack configurations, picking paths, and automation layouts before making physical changes.

Throughput Simulation: Evaluating how varying demand levels or equipment breakdowns impact order fulfillment rates.

Maintenance Planning: Predicting wear and tear on machinery, conveyors, or AMRs (Autonomous Mobile Robots) to reduce downtime.

Benefits

- Reduced operational costs through optimized workflows and resource allocation.

- Improved scalability by simulating the impact of increased demand or new product lines.

- Enhanced accuracy in inventory management, reducing stockouts and waste.

Example

A major retailer implemented a digital twin of its distribution center to simulate order fulfillment during the holiday season. By modeling different staffing levels and picking strategies, the retailer reduced order processing time by 15% and cut overtime costs by 10%.

Enhancing Fleet Management with Digital Twins in Distribution

For distributors operating large fleets, Digital Twins offer a powerful way to monitor, simulate, and enhance performance:

Predictive Maintenance: Anticipating mechanical issues based on telemetry data from vehicles.

Route Simulation: Testing alternative delivery routes to minimize fuel use and improve on-time delivery.

Driver Performance Monitoring: Using behavioral analytics to reduce idling, speeding, and fuel waste.

Benefits

- Lower fuel and maintenance costs through predictive analytics and route optimization.

- Increased delivery reliability by anticipating and mitigating disruptions.

- Enhanced sustainability by optimizing routes and transitioning to eco-friendly vehicles.

Example

A logistics company used a digital twin to simulate its fleet operations across a 500-vehicle network. By optimizing routes and scheduling maintenance based on predictive insights, the company reduced fuel costs by 12% and improved on-time delivery rates by 20%.

Enhancing Delivery Network Performance

Delivery networks connect warehouses, fleets, and customers, requiring seamless coordination to meet demand. Digital twins provide a holistic view of the network, enabling end-to-end optimization.

Key Applications

Simulate demand surges and proactively adjust staffing or inventory placement.

Run “what-if” scenarios for disruptions such as weather events or supply shortages.

Balance cost vs. service level by testing different route, schedule, and delivery partner combinations.

By visualizing how each decision ripples through the network, companies can achieve the optimalbalance between speed, cost, and customer satisfaction.

By visualizing how each decision ripples through the network, companies can achieve the optimal balance between speed, cost, and customer satisfaction.

Challenges and Considerations

While digital twins offer significant benefits, their implementation in distribution systems comes with challenges:

Data Integration: Digital twins require high-quality, real-time data from diverse sources, which can be difficult to aggregate and standardize.

Technology Costs: Building and maintaining digital twins involves investment in IoT infrastructure, cloud computing, and analytics platforms.

Scalability: Simulating large-scale distribution networks demands significant computational resources, which in turn require robust IT systems.

Skill Gaps: Organizations need skilled personnel to develop, manage, and interpret digital twin outputs effectively.

To address these challenges, companies should start with pilot projects, focusing on specific areas such as a single warehouse or fleet segment, before scaling to the entire network.

Conclusion

As distribution networks grow more dynamic, the ability to see, predict, and optimize every component in real time becomes a strategic necessity. Digital Twins turn this vision into reality—offering distributors an intelligent, data-driven foundation to run smarter warehouses, more efficient fleets, and resilient delivery networks. LaceUp Solutions offers DSD, Route management, and WMS that can support automated warehouse strategies. Contact us for more information on our solutions.

I hope this article about Digital Twins in Distribution have been helpful. I will continue to post information related to management, distribution practices and trends, and the economy in general. Our channel has a lot of relevant information. Check out this WMS walkthrough video.

Sorry, the comment form is closed at this time.