Distribution Operation best practices

A distribution operation is one of the fastest growing economic sectors, even with the changes brought by COVID in the supply chain sector. According to IbisWorld, the expected growth of the wholesale market in the US for 2023 will be 2.3% with a 3.9% rate in the coming years. But it is also a low-margin business with strong competition. I have covered best practices associated with warehousing and distribution operations in several articles. But in this article I bring you a compilation of the best practices that have yielded the best results in terms of productivity and profits.

Distribution Operation processes

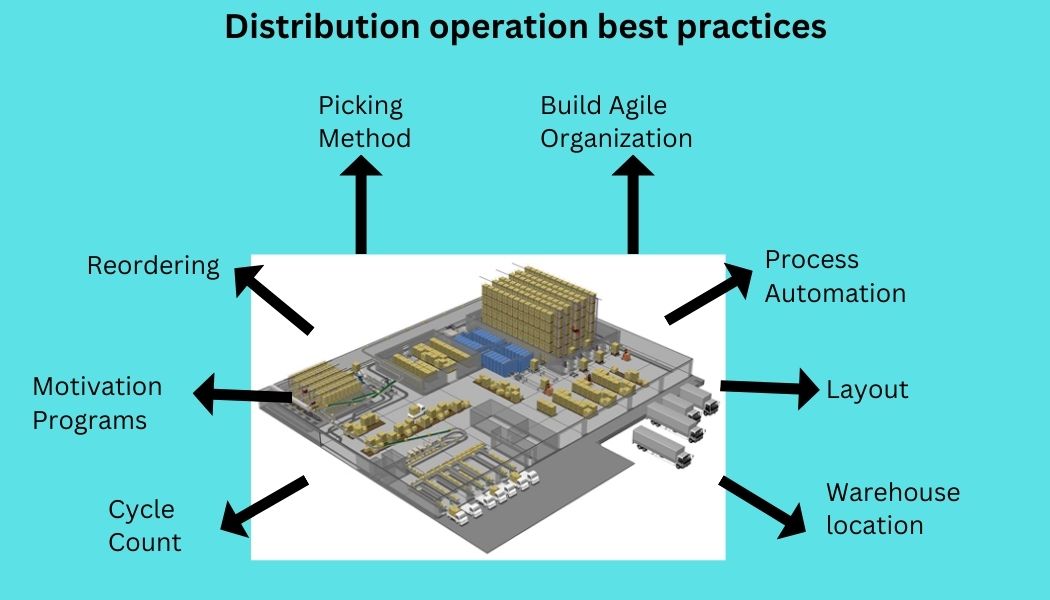

The image below illustrates the processes associated with a distribution operation.

Distribution Operation best practices

1. Optimize warehouse location

Warehouse location has a profound impact on how effective, efficient, and profitable your distribution operation can be. Delivery costs, time to serve an order, reorder points, labor availability, and taxation are all affected by your warehouse location.

2. Define layout

Warehouse layout design affects all warehouse processes, from receiving to put away, picking, and delivery. There are three elements associated with warehouse layout design that impact not only picking efficiency, but also in the warehouse processes related to product movement. They are: arrangement of the racks along the storage space, warehouse traffic flow throughout the storage area, and product space allocation.

3. Automate as much as possible

Warehouse automation is the process of automating the movement of inventory into, within, and out of warehouses to customers with minimal rework and minimizing human error. Automating your distribution operation involves state-of-the-art routing and storage technology and software that integrates with your ERP.

4. Select the best picking method

Of all warehouse processes, picking takes up more than 50% of a warehouse’s labor and 50% of a warehouse´s overhead. There are several picking methods you can use to pick your orders. You can use a single method or a combination of them to optimize the fulfillment of your orders. Choose carefully which ones you will use and under what circumstances.

5. Define your reorder process

The reorder point is the most important thing when it comes to purchasing from a vendor. It enables you to keep the right stock in your warehouse. If your reorder points are not frequent enough, you will have lost sales; conversely, if they are too far apart, inventory will pile up and you will have unnecessary capital tied up in inventory that doesn’t move. So, your reorder point must take into account the speed of product turnover and the reliability of the supplier.

6. Train and motivate your employees

It is well known that committed employees go to great lengths to make things right. It is also widely documented that organizations with employee motivation programs tend to produce more engaged employees than companies that do not act on employee motivation and integration. When designing your motivation program, select the most adequate combination of motivation techniques, considering human nature as the differentiating factor. I covered extensively this topic in “Motivation techniques to develop committed employees”

7. Conduct regular cycle counts

One of the key goals of any warehouse operation is to ensure the accuracy of inventory information. Errors in any process related to inventory movement can alter the veracity of the inventory. There are two ways to count inventory: count all items or cycle count. A cycle count is a perpetual inventory audit procedure, in which you follow a sequence of checks that is repeated periodically on a subset of the inventory. That is why inventory cycle count has become the standard practice of any warehouse.

8. Build a resilient and agile organization

In today’s world, emergent technologies, COVID uncertainties, and socioeconomic unrest are constantly disrupting the business environment. This has been especially true in the wholesale and distribution industry. Resilient organizations with agile processes have shown better results when it comes to adaptation and recovery. You can dwell on this topic in a recent article I wrote on this subject.

I hope this article has been helpful to you. I will continue to post information related to warehouse management, distribution practices and trends, and the economy in general. If you are interested in this article or want to learn more about Laceup Solutions, please subscribe to stay updated on future articles.

There is a lot of relevant information on our channel. Check out this video on things to consider when starting your distribution operation.

Sorry, the comment form is closed at this time.