DSD Challenges: Inventory Management and Visibility

Direct Store Delivery (DSD) is a widely used distribution method where products are delivered directly to retail stores by the manufacturer or distributor, bypassing traditional distribution centers. We have written about the benefits of a DSD model to your distribution operation and even developed a spreadsheet to calculate the ROI of implementing such a model. However, it also presents significant challenges, particularly in inventory management and visibility. In this article, I explore the main DSD Challenges and discuss strategies to overcome them.

DSD Challenge Related to the Complexities of Inventory Management

One of the primary DSD challenges is the increased complexity of inventory management. These are the main inventory DSD challenges.

High Inventory Turnover: DSD environments often experience high inventory turnover due to the fast-paced nature of delivering directly to stores. Managing this rapid turnover requires accurate demand forecasting and efficient replenishment processes. Inaccurate forecasts can lead to stockouts or overstock situations, impacting sales and profitability.

Diverse Product Range: DSD typically involves a wide range of products, from perishable goods like dairy and bakery items to non-perishable items like beverages and snacks. Each product category has its own inventory management challenges, such as varying shelf lives, storage requirements, and demand patterns. Balancing these diverse needs is crucial for maintaining optimal inventory levels.

Frequent Deliveries: Frequent deliveries are a hallmark of DSD, aiming to keep shelves stocked and products fresh. However, managing numerous small shipments can complicate inventory tracking and increase the risk of errors. Effective route planning and delivery schedules are essential to minimize disruptions and maintain efficient inventory flows.

Fragmented Data: Unlike traditional models where the inventory resides in a central warehouse, DSD involves multiple touchpoints – distributors, delivery vehicles, and retail backrooms. This distributed network can lead to siloed data, making it difficult to get a real-time picture of stock levels.

Limited Communication: Communication gaps often exist between retailers and suppliers. Discrepancies in ordering, deliveries, and shelf stocking can create blind spots, leaving both parties unsure of actual product availability.

The Visibility DSD Challenge

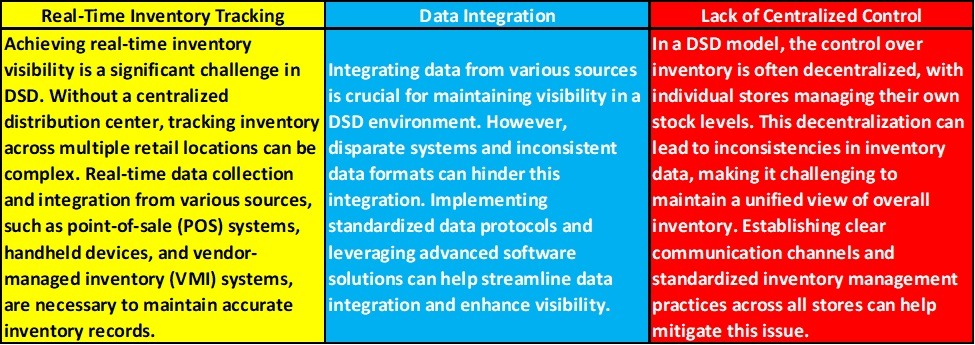

Maintaining visibility in a DSD environment is another significant challenge. These are the challenges you face.

Strategies to Overcome DSD Challenges

Advanced Inventory Management Systems Investing in advanced inventory management systems that provide real-time tracking and analytics can significantly improve inventory visibility. These systems can integrate with POS data, handheld devices, and VMI systems to comprehensively view inventory levels across all retail locations.

Collaborative Planning and Forecasting: Collaborative planning and forecasting between manufacturers, distributors, and retailers can enhance demand accuracy and improve inventory management. Regular communication and data sharing can help all parties align their strategies and respond quickly to changes in demand.

Technology: By using e-technology such as IoT (Internet of Things) devices, RFID (Radio-Frequency Identification) tags, and blockchain, retailers can enhance inventory visibility and traceability. IoT devices and RFID tags, with their real-time updates on inventory levels and product movement, and blockchain, with its ability to ensure data integrity and transparency throughout the supply chain, offer significant advantages in inventory management.

Training and Standardization Comprehensive training for store personnel on inventory management practices and standardizing processes across all retail locations can help reduce discrepancies and improve overall inventory accuracy. Consistent practices ensure that all team members follow the same procedures, improving inventory control and visibility.

Conclusion

While DSD offers a direct line from production to purchase, it demands a high level of coordination and technological support to manage effectively. Businesses that can master the challenges of inventory management and visibility in a DSD environment stand to gain a competitive edge in the fast-paced world of retail distribution. Laceup Solutions’ integrated product suite fully supports DSD inventory management and visibility. If you want to learn more, send us your information so we can schedule a meeting.

I hope this article about DSD Challenges has been helpful to you. I will continue to post information related to warehouse management, distribution practices and trends, and the economy in general. There is a lot of relevant information on our channel. Check this video on Why You Need a DSD Software.

Sorry, the comment form is closed at this time.