Enhancing Supply Chain Efficiency in Sales and Distribution

In a recent article, I examined the impact of supply chain disruptions in sales and distribution, and the strategies to mitigate risks and build resilience. In this article, I explore various methods to optimize supply chain efficiency, covering demand forecasting, inventory management, logistics optimization, and technology for streamlined processes.

Demand Forecasting: The Foundation of Supply Chain Efficiency

Demand forecasting is the cornerstone of supply chain management. Accurate predictions of customer demand enable companies to plan production, procurement, and distribution processes more efficiently. Here are some strategies for improving demand forecasting:

Data-Driven Forecasting: Leverage historical data, market trends, and customer insights to create more accurate demand forecasts. Advanced analytics and machine learning algorithms can help identify patterns and make precise predictions.

Collaborative Forecasting: Collaborate with key stakeholders, including sales and marketing teams, to gather input and insights for forecasting. Combining multiple perspectives can lead to more accurate predictions.

Continuous Monitoring: Regularly monitor and adjust forecasts as market conditions change. The ability to adapt quickly to shifting demand patterns is crucial for supply chain efficiency.

Inventory Management: Balancing Supply and Demand

Effective inventory management is essential for optimizing supply chain efficiency. Maintaining the right balance between excess and insufficient inventory can be achieved through the following methods:

Just-in-Time (JIT) Inventory: Implement JIT principles to minimize excess inventory and reduce holding costs. This approach ensures that products are ordered and received precisely when needed.

Safety Stock Analysis: Determine optimal safety stock levels to mitigate the risk of stockouts while minimizing excess inventory. This involves considering factors such as lead times and demand variability.

ABC Analysis: Classify inventory items based on their value and importance. Focus on optimizing the management of high-value, high-demand items while adopting more flexible approaches for lower-value items.

Logistics Optimization: Streamlining Distribution

Efficient logistics play a pivotal role in supply chain efficiency. To optimize distribution operations, consider the following strategies:

Route Optimization: Utilize route planning software to optimize delivery routes, reduce fuel consumption, and minimize delivery times. Real-time tracking and monitoring systems provide visibility into driver performance and vehicle location.

Warehouse Automation: Implement automation technologies to streamline warehouse operations. Automated picking, packing, and sorting processes can significantly reduce order fulfillment times.

Cross-Docking: Adopt cross-docking strategies to minimize storage time and handling costs.

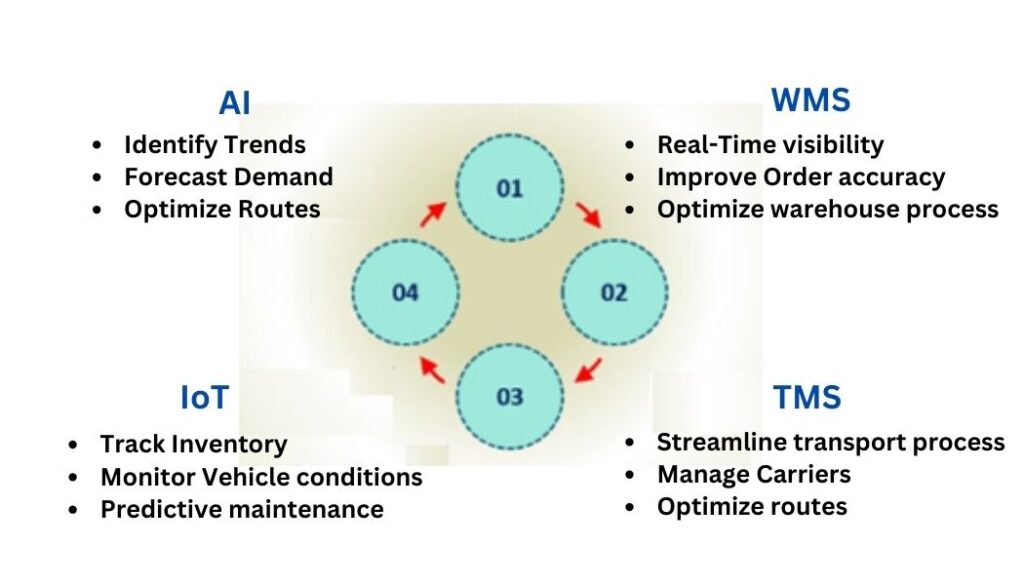

Leveraging Technology: Streamlined Processes for Supply Chain Efficiency

The integration of technology can revolutionize supply chain operations. Consider the following technology-driven solutions:

LaceUp Solutions

Enhancing supply chain efficiency in sales and distribution operations is essential for modern businesses seeking to remain competitive. LaceUp Solutions can help you to enhance your supply chain processes.

I hope this article has been helpful to you. I will continue to post information related to warehouse management, distribution practices and trends, and the economy in general. If you want to know how Laceup’s solutions can help you with e-commerce, click the link below to schedule an exploratory meeting.

There is a lot of relevant information on our channel. Check this video on Route Optimization.

Sorry, the comment form is closed at this time.