Guidelines for a successful WMS implementation (Part 1)

If you have a distribution or a warehousing operation you need to very carefully weigh when and how to proceed with a WMS implementation. In What is a Warehouse Management System we explained what a WMS is and in Features a Warehouse Management System must have, we went over how to select your WMS. But in this two-part article, I will provide a general guideline to the issues you need to consider for a successful WMS implementation. In this first part, I will concentrate on the organizational issues that you must consider in order to get rid of the emotional obstacles that could hinder a successful implementation.

Organizational issues to consider in a WMS implementation

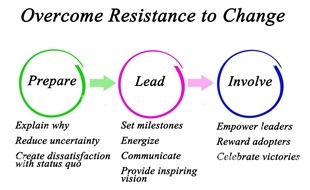

A WMS implementation implies a profound change in the way the whole organization thinks and works; and this mind setting change must permeate all levels of the Organization, from warehouse and administrative workers, to managers and up to stake holders. Let’s go over what the potential hurdles are and how to overcome them.

At the worker level: Attempting to change the way things are done without proper preparation will lead to:

Resistance: People tend to react to imposed changes. For example, a receiver might not understand why he needs to break a pallet and scan the products and take them to a specific bin instead of simply relying on the invoice and placing the product in the nearest bin. But if the benefits of doing it the new way have been explained, he will be more prone to comply.

Lower initial efficiency: even if workers have understood the advantages of the new system, it takes time for them to get used to the new set of tasks to be performed. It is like putting together a puzzle: the first time you will spend more time since you are getting to know it; but the more times you do it, the faster you will become until you reach your maximum efficiency.

Potential mistakes: Not training the personnel in the use of a new system might lead to the incorrect use of the system which, in turn, leads to mistakes such as misplaced products, wrong storage of items, etc.

All of these potentials threats to a successful WMS implementation can be minimized with two actions:

- You need to “sell the system” to your employees before entering the training or implementation phases. Make sure they understand the benefits, for the company, and for themselves. You can do this with special workshops, regular meetings, and internal marketing tools, like billboards, brochures or email campaigns.

- System users need to be trained beyond user guides and manuals. The best way to do this is with hands on experience reinforced by manuals and guidelines.

Managerial level: The interests of managers are different from those of regular employees. They will be more concerned about the impact on productivity and profits. You cannot achieve a successful WMS implementation without the management team on board; and the only way to do that is by addressing their concerns. There are two ways to do it:

- Consider involving them in the economic analysis of the planning phase. Make them work projections of the KPIs with all the benefits associated with the system. What happens if picking errors are reduced by 75%? How will gross profit be affected? Make them realize for themselves how the operation works and how they will benefit from the system.

- Select a champion who will lead the implementation. If this champion is respected by workers and supported by the organization’s management, the chances of a successful implementation are greatly increased.

The figure below illustrates the process.

Stakeholder level: This level will be more concerned in the ROI of the project. Although new trends in the warehouse management system are driving down the overall costs of a WMS project, they can still be expensive and, in our experience, many WMS implementations fail due to unreasonable expectations of the owners regarding time and rate for the return of their investment. Therefore, from the onset of the project, you must be sure that the operational benefits, the increase in gross profit derived from the reduction of errors, the optimization of purchases and the increase in efficiency, produce an adequate ROI in a reasonable payback time and that stakeholders are clear and comfortable with those figures. I will be addressing this topic in a future article.

I hope this article has been helpful to you and watch out for the second part coming next week. I will continue posting information related to warehouse management, distribution practices and trends, and the economy in general. If you are interested in this article or want to learn more about Laceup Solutions, please subscribe to stay updated on future articles.

There is a lot of relevant information on our channel. Check out this video about a customer’s experience with the FDA inspection.

Sorry, the comment form is closed at this time.