How to Calculate Warehouse Capacity: A Practical Guide for Distributors and Logistics Managers

Warehouse capacity calculation is critical for optimizing storage, improving operational efficiency, and ensuring smooth logistics. It involves determining a warehouse’s total storage capacity and assessing how much inventory can be effectively stored while maintaining accessibility and safety. In this article, I explore the key concepts, methods, and considerations for calculating warehouse capacity.

Why Capacity Calculation Matters

Understanding Different Types of Warehouse Capacity

When we talk about capacity, we often refer to a few distinct concepts:

Nominal Capacity: This is the theoretical maximum space available within the four walls of your warehouse. It’s calculated by simply multiplying the storage areas’ length, width, and height. While easy to determine, nominal capacity rarely reflects the actual usable space.

Nominal Capacity=Length×Width×Height

Maximum Storage Capacity: This takes into account the physical constraints of the warehouse layout, including aisles, columns, loading docks, and non-storage areas like offices and break rooms. It represents the total volume available for storage after deducting these necessary spaces.

Maximum Storage Capacity=Total Warehouse Volume−Volume of Non-Storage Areas

Usable Storage Capacity: This is the most practical measure and reflects the actual space available for storing goods, considering factors like racking systems, pallet dimensions, safety clearances, and the need for operational movement. It’s the space where you can realistically place and retrieve inventory.

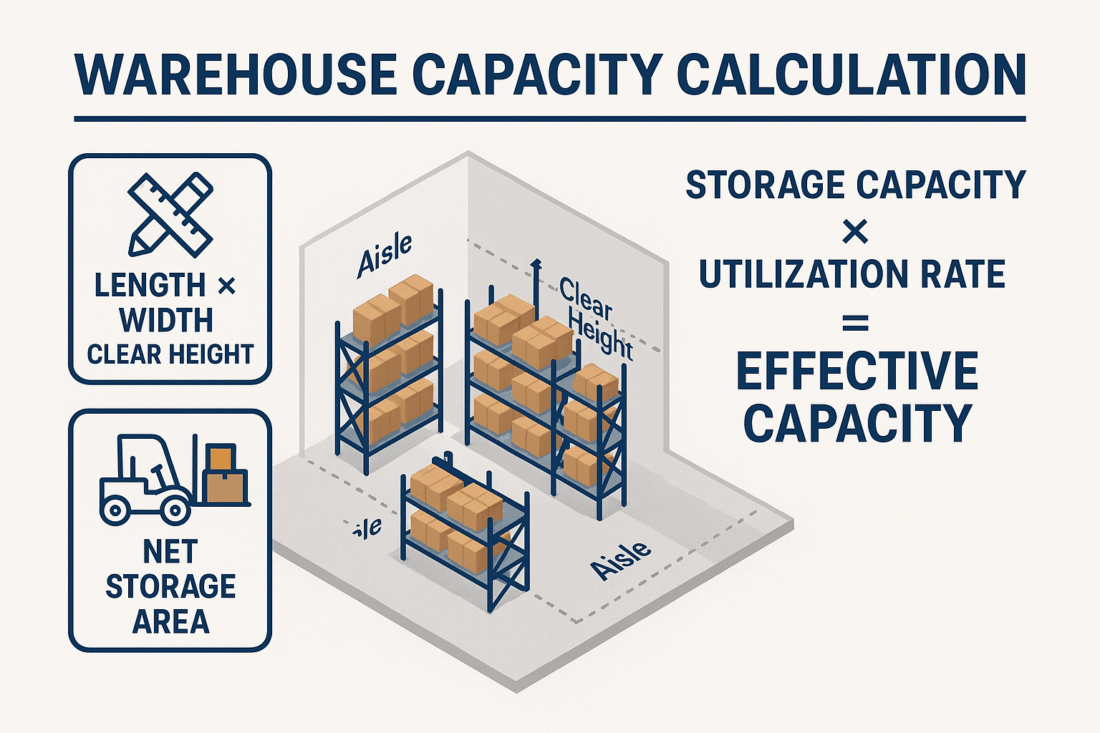

Effective Capacity: This goes a step further by considering the actual utilization rate of the usable storage capacity. Factors like inventory turnover, product mix, and storage strategies influence how effectively the usable space is employed. A warehouse might have significant usable capacity, but if its organization is inefficient, the effective capacity will be lower.

Key Factors Influencing Warehouse Capacity

Several factors play a crucial role in determining the usable and effective capacity of a warehouse:

Storage Systems: The type of racking or shelving used significantly impacts capacity. Pallet racking, shelving units, flow racks, and automated storage and retrieval systems (AS/RS) offer varying levels of storage density.

Aisle Width: Wider aisles facilitate more effortless movement for forklifts and personnel but reduce storage space. Finding the optimal balance is crucial for efficiency and capacity.

Building Layout: The presence of columns, loading docks, doors, and other structural elements affects the flow and usable storage areas. For more information on layout design and optimization, see this article.

Inventory Characteristics: The stored products’ size, shape, and weight influence how densely they can be packed.

Safety Regulations: Fire codes and safety regulations often dictate minimum aisle widths and clearance requirements, impacting usable space.

Operational Processes: Order picking methods, inventory management strategies (like FIFO or LIFO), and the frequency of warehouse traffic all influence how effectively space is utilized.

Step-by-Step Guide to Calculating Warehouse Capacity

Step 1: Measure the Total Warehouse Space

Calculate the total cubic or square footage:

- Cubic feet = length × width × clear height

- Square feet = length × width

Clear height refers to the maximum height that can be safely used for storage.

Step 2: Identify the Storage Area

Exclude non-storage areas such as:

- Offices

- Restrooms

- Aisles

- Loading docks

- Mechanical/electrical rooms

This gives you your net storage area.

Step 3: Calculate Storage Capacity

Based on your storage system:

For Pallet Racking:

- Number of rack positions × standard pallet dimensions = storage volume

- Example: 500 pallet positions × 64 cubic feet per pallet = 32,000 cu ft

For Shelving or Bins:

- Count the bins/shelves × average item dimensions

Step 4: Apply Utilization Factors

Due to layout constraints and safety considerations, warehouses rarely achieve 100% capacity. Use a utilization rate:

- 85–90% for pallet racking

- 70–80% for shelving/bin systems

- Lower for bulk storage

Example:

- Available storage capacity = 32,000 cu ft

- Utilization rate = 85%

- Effective capacity = 32,000 × 0.85 = 27,200 cu ft

Step 5: Monitor and Reassess Regularly

Warehouse conditions and inventory profiles change. Recalculate capacity:

- When product mix changes

- After layout changes

- Periodically, to ensure alignment with growth

Conclusion

Calculating warehouse capacity is not just about measuring space—it’s about understanding how that space is used and how it can be optimized. By assessing theoretical, storage, and effective capacities, distributors can make smarter decisions, reduce costs, and improve service levels. Laceup has solutions integrated with its DSD and WMS that allow you to optimize your WH capacity. If you want to learn more about our solutions, contact us.

I hope this article has been helpful to you. I will continue to post information related to management, distribution practices and trends, and the economy in general. Our channel has a lot of relevant information. Check out this video on How to Label Your Warehouse Bin Locations.

Sorry, the comment form is closed at this time.