Hybrid Warehousing Models: Balancing Physical Operations with Digital Twin Technologies

As distribution and logistics networks become increasingly complex, businesses are exploring innovative ways to optimize their warehousing operations. One emerging solution is integration of traditional physical warehouses with advanced digital technologies, including cloud-based systems and digital twins. In this article, I explore the benefits, key components, and challenges of a hybrid warehousing model.

What Is a Hybrid Warehousing Model?

A hybrid warehousing model combines the physical infrastructure of traditional warehouses with digital simulations and cloud-based platforms. Digital twins, or virtual replicas of physical warehouses, allow companies to monitor, simulate, and optimize warehouse operations in real-time. This model bridges the gap between physical assets and digital intelligence, creating a more responsive and data-driven supply chain.

Bridging the Physical and Digital Divide

The core concept of a hybrid warehouse revolves around leveraging digital simulations and cloud-based platforms to enhance and optimize the performance of physical warehouse operations. This approach addresses the limitations of both purely physical and purely digital solutions.

Physical Warehouses: While essential for storing and moving goods, they can be inflexible, prone to inefficiencies, and difficult to adapt to fluctuating demand.

Digital Twins: These virtual replicas of physical warehouses offer immense potential for simulation and optimization, but they lack the real-world execution capabilities of physical infrastructure.

Simulate and Optimize Layouts: Before implementing changes in the physical warehouse, businesses can use digital twins to simulate different layouts, storage configurations, and material flow patterns, identifying potential bottlenecks and optimizing space utilization.

Predictive Maintenance: Sensors within the physical warehouse can feed data into the digital twin, enabling predictive maintenance of equipment and minimizing downtime.

Demand Forecasting and Inventory Management: Cloud-based platforms can analyze historical data, market trends, and real-time information to provide accurate demand forecasts, enabling businesses to optimize inventory levels and reduce storage costs.

Real-Time Monitoring and Control: Digital dashboards can provide real-time visibility into warehouse operations, allowing managers to monitor key performance indicators, identify issues, and make informed decisions.

Optimized Picking and Packing: Digital simulations can determine the most efficient picking routes and packing strategies, minimizing travel time and maximizing throughput.

Benefits for Distribution and Logistics

The adoption of this model offers numerous benefits for distribution and logistics networks:

Increased Efficiency and Productivity: Businesses can significantly improve warehouse efficiency and productivity by optimizing workflows, reducing errors, and minimizing downtime.

Enhanced Agility and Responsiveness: Digital simulations and real-time data analysis enable businesses to quickly adapt to changing market conditions and customer demands.

Reduced Costs: Optimized inventory management, predictive maintenance, and efficient operations can save significant costs.

Improved Accuracy and Visibility: Real-time data and digital dashboards provide greater visibility into warehouse operations, enabling businesses to track inventory, monitor performance, and identify potential issues.

Enhanced Customer Experience: Faster order fulfillment, accurate deliveries, and improved transparency can enhance the customer experience and build brand loyalty.

Data-Driven Decision Making: The data provided by the hybrid system allows for better-informed decisions and constant process improvement.

Key Components of a Hybrid Warehousing Model

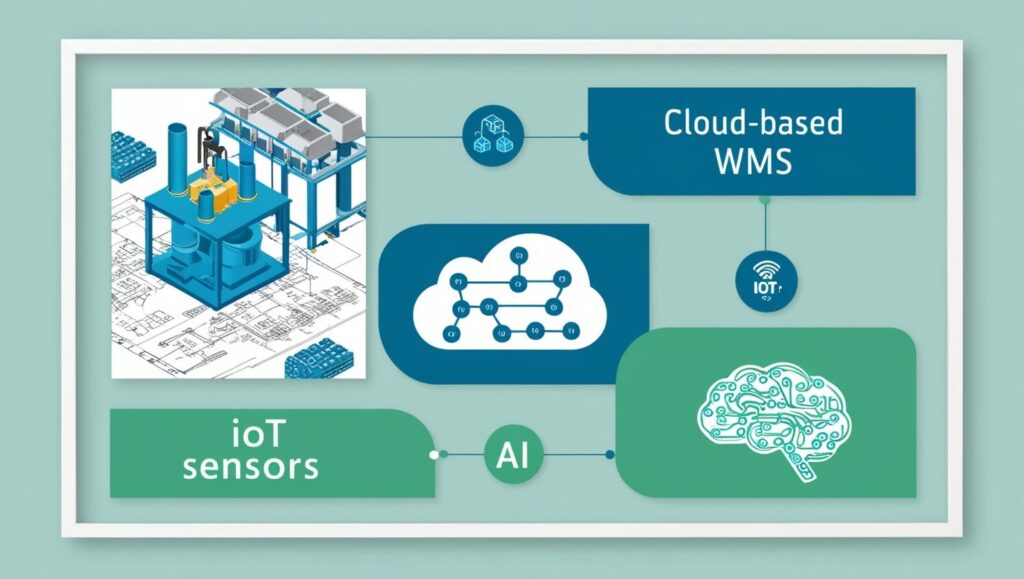

Digital Twin Technology: Virtual replicas of warehouses that simulate physical processes, enabling real-time monitoring, scenario testing, and process optimization.

Cloud-Based WMS: Centralized platforms that provide real-time access to inventory data, order statuses, and operational performance metrics from any location.

IoT Sensors and Automation: Connected devices that track inventory movements, monitor equipment health, and automate routine tasks such as picking, packing, and sorting.

AI and Machine Learning: Predictive analytics that optimize inventory levels, forecast demand, and streamline order fulfillment processes.

Challenges and Considerations

While hybrid warehousing models offer numerous benefits, businesses must address several challenges to maximize their effectiveness:

- Integration Complexity: Ensuring seamless integration between digital twins, WMS platforms, and IoT devices requires careful planning and robust IT infrastructure.

- Data Security: Protecting sensitive operational data is essential, especially when using cloud-based systems. Implementing strong cybersecurity measures is crucial.

- Employee Training: Warehouse staff must be trained to use new digital tools and interpret data insights, ensuring that technology enhances rather than disrupts daily operations.

Conclusion

Hybrid warehousing models represent the future of distribution and logistics, combining the physical capabilities of traditional warehouses with the intelligence and flexibility of digital technologies. Businesses can optimize their operations, improve decision-making, and enhance supply chain resilience by leveraging digital twins, cloud-based platforms, and IoT sensors. As these technologies continue to evolve, companies that adopt a hybrid approach will be well-positioned to thrive in an increasingly competitive and dynamic market. LaceUp’s solutions provide a robust platform for distribution companies to seamlessly integrate different systems, allowing you to monitor logistics costs closely. If you want to learn more about LaceUp’s solutions, give us your information to schedule a meeting.

I hope this article has been helpful to you. I will continue to post information related to warehouse management, distribution practices and trends, and the economy in general. Our channel has a lot of relevant information. Check out this video about Integrating Warehousing Software.

Sorry, the comment form is closed at this time.