Impact of Integrating WMS, TMS, and DSD on Overall Profit

Businesses continuously seek ways to optimize their operations, reduce costs, and maximize profits. One of the most effective strategies to achieve these goals is the integration of key operational systems: Warehouse Management Systems (WMS), Transportation Management Systems (TMS), and Direct Store Delivery (DSD). Each system plays a vital role in the supply chain, and their integration can significantly impact overall profit. In this article, I explore the benefits of Integrating WMS with the other operational systems.

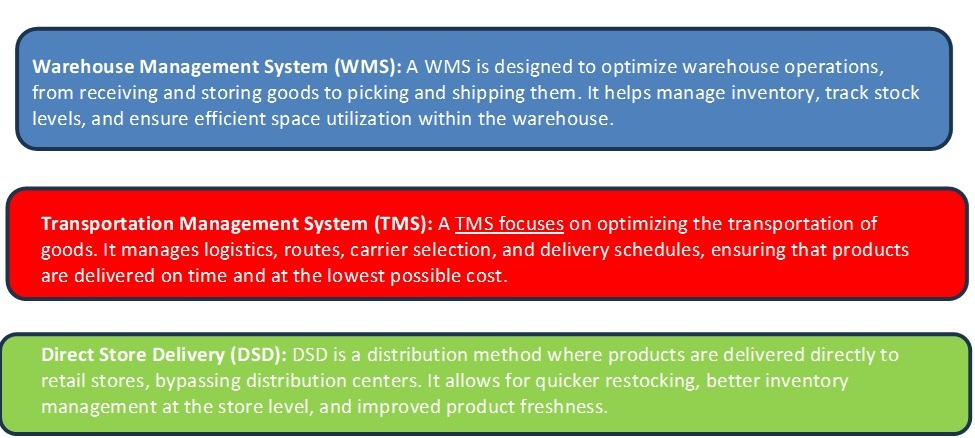

Understanding the Systems

Benefits of Integrating WMS with TMS and DSD

Enhanced Operational Efficiency: Integrating WMS, TMS, and DSD creates a seamless flow of information across the supply chain. Real-time data sharing improves warehouse and transportation logistics coordination, leading to more efficient order fulfillment. For example, when an order is picked up in the warehouse, the TMS can immediately plan the most efficient route for delivery, minimizing delays and reducing transportation costs.

Reduced Operational Costs: By optimizing warehouse operations and transportation logistics, businesses can significantly reduce operational costs. A well-integrated system minimizes errors, reduces manual labor, and enhances resource utilization. For instance, accurate inventory management through WMS reduces excess stock and associated carrying costs, while TMS optimizes delivery routes, cutting fuel expenses and labor costs.

Improved Customer Satisfaction: Quick and accurate deliveries are crucial for maintaining customer satisfaction. Integration ensures that products are delivered on time and in optimal condition. DSD integration, in particular, helps maintain product freshness and availability, enhancing the customer experience and fostering brand loyalty.

Better Inventory Management: Integrating WMS, TMS, and DSD systems provides real-time visibility into inventory levels across the supply chain. This visibility allows for better demand forecasting and inventory planning, reducing the risk of stockouts or overstock situations. Improved inventory management directly translates to lower holding costs and increased sales opportunities.

Increased Agility and Responsiveness: Integration enhances a company’s ability to respond quickly to market changes and customer demands. For example, suppose there is a sudden surge in demand for a product. In that case, the integrated system can quickly adjust warehouse operations and transportation plans to meet this demand, ensuring that shelves are stocked and sales are not lost.

Case Study: Real-World Impact

Consider a mid-sized distributor who integrated their WMS, TMS, and DSD systems. Before integration, they faced issues such as delayed deliveries, high transportation costs, and frequent stockouts. After integration, they experienced the following improvements:

- 30% Reduction in Transportation Costs: Optimized routing and better load planning reduced fuel usage and labor expenses.

- 25% Increase in On-Time Deliveries: Improved warehouse operations and transportation coordination led to more reliable delivery schedules.

- 20% Reduction in Inventory Holding Costs: Better inventory management reduced excess stock and improved cash flow.

- 15% Increase in Sales: Enhanced product availability and freshness led to higher customer satisfaction and repeat business.

Conclusion

Integrating WMS, Transportation Systems (TMS), and Direct Store Delivery (DSD) can profoundly impact a business’s profitability. If you want to learn more about Laceup Solutions, send us your information so we can schedule a meeting.

I hope this article has been helpful to you. I will continue to post information related to warehouse management, distribution practices and trends, and the economy in general. There is a lot of relevant information on our YouTube channel. Check this video on Methods to Integrate Warehousing Software.

Sorry, the comment form is closed at this time.