Inventory Management of raw material in batch production

How track weighted raw material

Inventory tracking and inventory management and tracking is a challenge for any company as we have discussed in previous posts. But the problems escalate when it comes to manufacturers of products that involve raw materials whose measure unit is weight, like pharmaceuticals or food processing companies, when doing batch production. There are several areas of concern to these types of manufacturers in terms of raw material inventory management:

- Optimal raw material location to pick up from

- Quantity of raw material used for a given batch

- Raw material cycle count

- Production lot traceability

Today I am going to tell you how a good inventory management software will track weighted raw materials to minimize your waste and increase your production yield and your warehouse productivity. You can also watch this related video.

If you have a WMS implemented following the guidelines we gave in our post on “What is a Warehouse Management System (WMS)” or in our “Live Tour of a Real Warehouse Management System”, the receiving, storage, and picking of products is not a problem and you will know exactly where your ingredients are and where to pick them from. This is the most critical issue: your WMS system must tell you exactly how much of the product that is supposed to go on that batch order is residing in that bin location. Then you can pick the product.

1. Optimal material location to pick up from

When a batch order for production of the finished good is received, you pick the raw material from the bins and send it over to production. They take the quantities needed and return the product to the location of the raw materials. Let’s say that they take five pounds of a certain ingredient that is going to be used in production. They remove it from the bin location by scanning the bin location and then they proceed to take it over to the production area. That is going to initiate a transfer from that bin location to the production area where that theoretical quantity will get consumed.

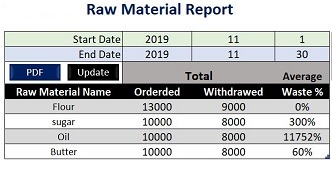

2. Quantity of raw material used for a given batch

This assumption is the key for those of you that have raw materials with a weight associated with them. As an example, suppose you consume two and a half pounds of an ingredient to manufacture a product. For argument’s sake let’s say that it is a five-pound box, but when it comes back to the scale in your raw materials warehouse, it weighs 2.3 pounds. That means that you actually consumed 2.7 pounds and you lost 0.2 pounds of that item. Our WMS system will record that for you. Additionally, when you scan the item, the system will re-associate the newly updated weight to that particular case and next time you have to pick it, the system will tell the picker exactly where to take that case, how many pounds it contains, and what bin to put in it.

3. Raw material count

So far we have covered receiving and production. The next thing we need relates to how we are supposed to count these raw materials. Counting is really a straightforward process: all you have to do is walking up to any bin location, scan the bin and the WMS system or inventory management software will tell you exactly what is supposed to be in there. Then you start counting or weighing the goods within the bin location and you input that into the handheld. The system will adjust any differences and export them over to the accounting system.

4. Production lot traceability

Lot traceability of raw materials is not only required by the FDA and USDA but desired by you and your supplier to restrict the amount of product potentially affected in case of a recall and implement your inventory rotation policy. The key for lot traceability is the labeling of the product. As we explained in our video on “How To Label Your Warehouse Bin Locations” the label of the raw material received, as well as the finished product, must contain the exact location in the warehouse and the information about the product, including lot, date and time of production, and expiration date. This type of labeling, paired with a good WMS, will provide you with full visibility on the whereabouts of your material and finished products.

I hope this information helps you optimize your warehouse management. We will continue publishing information related to warehouse management and distribution practices. If you are interested in this article or want to learn more about Laceup Solutions, register to keep you updated on future articles.

I hope this information helps you optimize your warehouse management. We will continue publishing information related to warehouse management and distribution practices. If you are interested in this article or want to learn more about Laceup Solutions, register to keep you updated on future articles.

Sorry, the comment form is closed at this time.