Live Demo of WMS Processes Part 3: Replenishment

In previous articles about how the warehouse processes should work using a WMS, we covered the receiving and the putaway processes. In this article, we explore how a WMS can streamline the replenishment process, reduce errors, and improve overall warehouse performance.

Understanding Replenishment in Warehousing

Replenishment is the process of moving inventory from reserve storage to primary picking locations to ensure that there is always sufficient stock available to fulfill orders. The goal is to minimize stockouts and maintain an optimal level of inventory in picking locations to maximize picking efficiency and accuracy.

Features of a WMS to Effectively Replenish Products

Here is how a WMS can enhance the replenishment process:

Real-Time Inventory Visibility: A WMS provides real-time data on inventory levels, enabling warehouse managers to monitor stock levels in picking locations and trigger the task when necessary.

Automated Triggers: Based on predefined rules and thresholds, a WMS can automatically generate replenishment tasks when inventory levels fall below a certain point, ensuring timely replenish products and reducing the risk of stockouts.

Optimized Strategies: A WMS can support various refill strategies, such as demand-based, wave, or opportunity replenishment, allowing warehouses to adopt the most suitable approach based on their operations and inventory turnover.

Efficient Task Allocation: The system can assign replenishing tasks to warehouse personnel based on their location, workload, and skill set, optimizing labor utilization and reducing travel time within the warehouse.

Data-Driven Decision Making: By analyzing historical data, a WMS can provide insights into inventory trends and help warehouse managers make informed decisions about reorder points, safety stock levels, and replacement frequencies.

Step-by-Step Guide to Replenish Products in a real WMS

Step 1: Capture Sales Orders

Start by capturing the ten sales orders in your back office system. These are the orders that need to be picked and packed for tomorrow.

Step 2: Create a Wave

Using your back office system, create a wave for the sales orders. This process groups the orders together and helps in efficient picking and packing.

Step 3: Generate Replenishment Tasks

When you create a wave, the system should automatically generate replenishment tasks. These tasks are instructions for your forklift operator to move pallets from upper storage locations to lower, more accessible locations to facilitate the picking process.

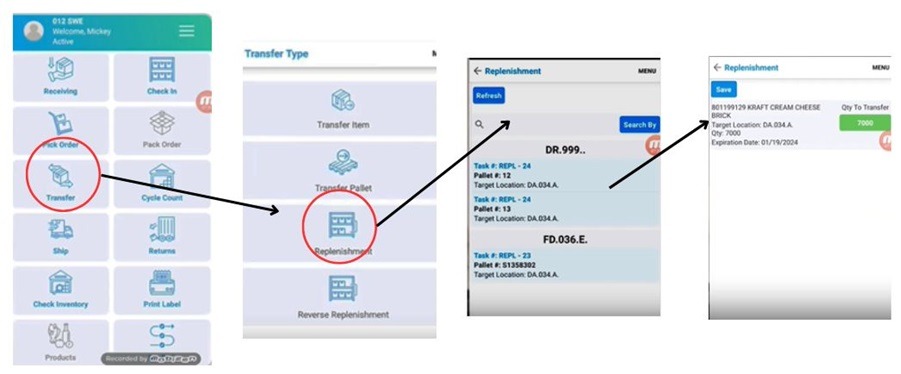

Step 4: Check Open Replenishment Tasks

Go to the replenishment section in your system to view the open replenishment tasks. For example, it might show that in location Dock 999, you need to transfer Pallet 12 and Pallet 13.

Step 5: Execute Replenishment Tasks

Start with the first task, which is to transfer Pallet 12 and confirm the quantity that needs to be moved.

After completing the first task, move on to the second task, and so on.

Step 6: Confirm Transfer

Scan the pallet and the location it’s going to in order to confirm the transfer. If you don’t have a scanner, ensure that the transfer is recorded manually in the system.

Step 7: Repeat as Necessary

Repeat the process for any remaining replenishment tasks. Ensure that all required pallets are moved to their designated locations before starting the picking process.

Step 8: Start Picking Process

Once all replenishment tasks are completed, you can begin the picking process for the sales orders.

The figure shows the screen associated to the steps associated with the transfer of products.

Conclusion

Laceup WMS products incorporate all the features required to optimize replenishing products, leading to inventory accuracy, reduce stockouts, and optimize warehouse operations. If you want to learn more, give us your information to schedule a meeting.

I hope this article has been helpful to you. I will continue to post information related to warehouse management, distribution practices and trends, and the economy in general. There is a lot of relevant information on our channel. Check this short live demo of the process.

Sorry, the comment form is closed at this time.