Managing Product Return in DSD Operations

Direct Store Delivery (DSD) operations involve the delivery of products directly from the manufacturer to the retailer, bypassing distribution centers. While DSD offers advantages as pointed out in a recent article, efficiently managing product return in DSD is essential to maintain profitability and customer satisfaction. In this article, I will explore the reasons behind product return in DSD operations, understand their impact, and provide strategies for streamlining the returns process.

Why a Store Might Return Products

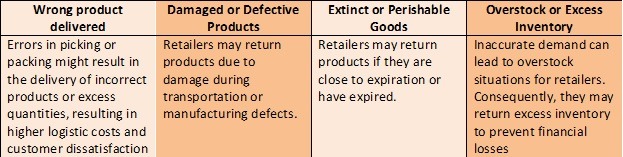

There are four reasons why stores return products to the distributor.

Impact of Product Return in DSD Operation

Product return in DSD operation has multiple implications.

Financial Implications: Returns can result in financial losses for the distributor and the retailer. Distributors may incur costs associated with product inspection, restocking, re-shipping, and disposal. Retailers have additional costs for processing returns, managing inventory, and potential markdowns to sell returned items.

Inventory Management Challenges: Product returns disrupt inventory management processes, leading to inaccurate stock levels and potential stockouts or overstocks, affecting demand planning, order fulfillment, and customer satisfaction.

Customer satisfaction: When customers encounter issues with a product and have a smooth and hassle-free return experience, it builds trust and confidence in the brand. Effective returns management demonstrates a commitment to customer needs, showing that the company stands behind its products. On the other hand, poor returns processes can lead to frustration, dissatisfaction, and negative word-of-mouth, tarnishing the brand’s reputation.

Operational Efficiency: Handling product returns can strain resources, including personnel, storage space, and transportation capacity. If not managed efficiently, returns can impact the overall operational efficiency of a DSD operation.

How to Streamline the Returns Process

Efficiently managing product return in DSD operations reduces financial losses, improves customer satisfaction, and strengthens retailer-supplier relationships. Consider the following practices:

Clear Return Policies and Procedures: Establish clear and concise return policies that outline acceptable reasons for returns, timelines, and condition requirements for returned products. Communicate these policies to retailers, providing them with the guidelines and instructions for initiating returns.

Use a Warehouse Management System (WMS): Implementing a WMS is crucial for effective product returns management. A WMS provides a centralized platform to track and manage returned products throughout reverse logistics processes. It enables you to streamline the flow of returned goods, optimize inventory levels, and reduce processing time.

Reverse Logistics Optimization: Implement efficient reverse logistics processes to handle returned products like establishing a dedicated area for receiving and inspecting returns, accurately reconciling returned products with existing inventory, and determining appropriate disposition routes (e.g., resale, refurbishment, or disposal) based on product conditions.

Data Analysis and Continuous Improvement: Leverage data analytics to gain insights into return reasons, patterns, and trends. Analyze the data to identify root causes and areas for improvement, allowing manufacturers and retailers to address product quality issues, packaging concerns, or delivery problems.

Integration with ERP Systems: Integrating the WMS with your Enterprise Resource Planning (ERP) system enhances visibility and data synchronization. This integration enables seamless communication between the WMS and other business systems, such as inventory management, order processing, and financials. It ensures accurate inventory reconciliation, efficient replacement order processing, and streamlined financial reporting for returned products.

Efficient Space Utilization: A WMS enables you to optimize space utilization in your warehouse or distribution center and minimize handling costs, resulting in operational expense reduction, faster processing, and quicker product reshipment.

I hope this article on product return in DSD operations has been helpful to you. I will continue to post information related to warehouse management, distribution practices and trends, and the economy in general. If you want to know how Laceup’s solutions can help you to streamline product returns, click the link below to schedule an exploratory meeting.

There is a lot of relevant information on our channel. Check out this video on How Credits Affect Distributor (DSD) Inventory.

Sorry, the comment form is closed at this time.