Managing Transportation Costs in a Volatile Market: A Guide for Distribution Companies

Transportation costs are a significant component of a distribution company’s expenses, and managing these costs effectively in a volatile market is critical to maintaining profitability and ensuring smooth operations. Factors such as fluctuating fuel prices, supply chain disruptions, labor shortages, and regulatory changes make cost control challenging. In this article, I explore different approaches to manage transportation costs in such an uncertain environment.

Strategies to Control Transportation Costs

Here are key strategies that distribution companies can implement to mitigate transportation costs while maintaining efficiency and service levels.

1. Optimize Route Planning and Fleet Utilization: One of the most effective ways to manage transportation costs is through route optimization. Advanced logistics software and AI-driven solutions can help distributors:

- Minimize miles driven by optimizing delivery sequences.

- Reduce fuel consumption through efficient routing.

- Improve vehicle utilization by maximizing load capacities.

- Adjust routes dynamically in response to real-time traffic and weather conditions.

Implementing GPS tracking and telematics solutions further enhances fleet efficiency by monitoring driver behavior, reducing idle time, and improving fuel economy.

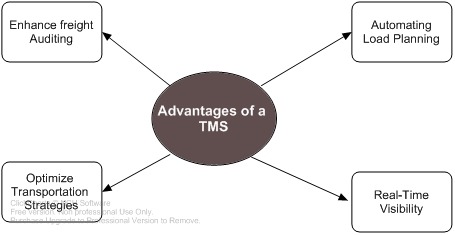

2. Leverage Transportation Management Systems (TMS): A robust Transportation Management System (TMS) enables distribution companies to streamline their logistics operations by:

- Automating load planning and carrier selection.

- Providing real-time visibility into shipments.

- Enhancing freight auditing and cost control.

- Optimizing multi-modal transportation strategies.

TMS solutions can integrate with Warehouse Management Systems (WMS) to create seamless logistics operations, reducing unnecessary expenses, and improving overall efficiency.

3. Diversify Carrier Relationships: Relying on a single carrier or transportation mode can be risky, especially in an unstable market. By diversifying their carrier base, distribution companies can:

- Secure competitive rates by leveraging multiple provider bids.

- Mitigate risks associated with carrier disruptions.

- Increase negotiation leverage in freight rate discussions.

Developing strategic relationships with regional and national carriers can provide flexibility and cost-saving opportunities.

4. Adopt Fuel Management Strategies: Fuel price volatility is a major cost driver in transportation. To mitigate fuel expenses, distribution companies can:

- Invest in fuel-efficient vehicles and alternative fuel options.

- Implement fuel hedging strategies to stabilize costs.

- Utilize fleet telematics to reduce unnecessary fuel consumption.

- Train drivers on eco-friendly driving techniques, such as reducing idling and maintaining optimal speeds.

5. Consolidate Shipments and Optimize Load Planning: Reducing the number of shipments by consolidating loads can significantly lower transportation expenses. Companies can implement:

- Cross-docking: Reducing storage time and handling costs by moving goods directly from inbound to outbound transportation.

- Backhauling strategies: Utilizing empty return trips to transport goods efficiently.

- Pooling and shared freight models: Partnering with other distributors to optimize truckloads and lower per-mile costs.

6. Monitor and Control Accessorial Charges: Unexpected surcharges, such as detention, demurrage, and re-delivery fees, can quickly add up. To mitigate these costs:

- Ensure efficient loading and unloading processes to avoid detention fees.

- Provide accurate shipment details to minimize additional handling costs.

- Monitor carrier performance and hold providers accountable for service levels.

7. Improve Demand Forecasting and Inventory Management: Accurate demand forecasting helps optimize transportation schedules and inventory distribution, preventing excess shipments and last-minute expedited freight costs. Distribution companies should:

- Leverage historical sales data and predictive analytics.

- Align inventory levels with expected demand to reduce emergency shipments.

- Implement Just-In-Time (JIT) delivery strategies to minimize unnecessary stock movements.

8. Automate Freight Auditing and Cost Analysis: Automating freight audit and payment processes ensures accurate invoicing and identifies cost-saving opportunities. Companies can:

- Use automated invoice reconciliation tools to prevent overpayments.

- Analyze freight spending trends to optimize procurement strategies.

- Regularly benchmark rates against industry standards to negotiate better contracts.

Conclusion

In a volatile market, managing transportation costs requires combining technology, strategic planning, and strong partnerships. By optimizing routes, leveraging a TMS, diversifying carriers, adopting fuel-saving strategies, and improving inventory management, distribution companies can achieve significant cost savings while maintaining operational efficiency. Proactive cost control measures will enable businesses to navigate market fluctuations and sustain profitability in the long run.

LaceUp’s solutions provide a robust platform for DSD companies to seamlessly integrate different systems, allowing you to monitor logistics costs closely. If you want to learn more about LaceUp’s solutions, give us your information to schedule a meeting.

I hope this article has been helpful to you. I will continue to post information related to warehouse management, distribution practices and trends, and the economy in general. Our channel has a lot of relevant information. Check out this on Route Optimization.

Sorry, the comment form is closed at this time.