Real-Time Cycle Counting for Inventory Accuracy

Inventory management is the backbone of any business dealing with physical goods, from retail stores to manufacturing and distributor warehouses. Accurate inventory tracking ensures smooth operations, reduces costs, and keeps customers satisfied. However, traditional methods like annual physical counts can be disruptive, time-consuming, and prone to errors. In this article, I explore what real-time cycle counting is, its benefits, and the techniques driving its success.

What Is Real-Time Cycle Counting?

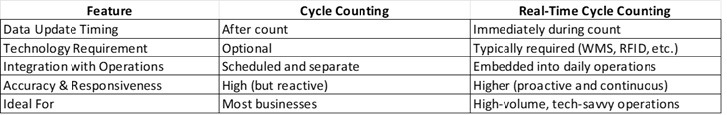

Cycle counting is a method of auditing inventory by regularly counting a small subset of items rather than shutting down operations for a complete physical inventory. Real-time cycle counting takes this a step further by integrating continuous, technology-driven updates into the process. Instead of relying on periodic manual checks, it leverages tools like barcode scanners, RFID (Radio Frequency Identification), and inventory management software to monitor stock levels as transactions happen, whether a sale, a restock, or a return. The table below summarizes the differences.

Key Differences at a Glance

Why Real-Time Cycle Counting Matters

Inventory inaccuracies can lead to overstocking, stockouts, lost sales, and unhappy customers. According to a study by the National Retail Federation, inventory shrinkage (losses due to theft, damage, or administrative errors) costs U.S. retailers billions annually. Cycle counting tackles these issues head-on by offering:

- Improved Accuracy: Frequent, automated checks reduce human error and ensure records match physical stock.

- Reduced Downtime: No need to halt operations for a full count—cycle counting happens seamlessly in the background.

- Cost Savings: Identifying discrepancies early prevents over-ordering or emergency restocks.

- Better Decision-Making: Up-to-date data empowers managers to optimize stock levels and forecast demand.

Key Techniques for Real-Time Cycle Counting

Implementing cycle counting in real-time requires a blend of strategy and technology. Here are some of the most effective techniques businesses are using today:

1. ABC Analysis with Real-Time Tracking

The ABC method categorizes inventory into three groups:

- A Items: High-value, low-quantity goods (e.g., electronics).

- B Items: Moderate-value, moderate-quantity items (e.g., clothing).

- C Items: Low-value, high-quantity products (e.g., screws or paper clips).

With real-time tracking, businesses prioritize counting “A” items more frequently, using tools like RFID tags or IoT-enabled sensors to monitor these critical assets continuously. Software dashboards then flag discrepancies instantly, allowing staff to focus efforts where they matter most.

2. Mobile Scanning and Barcode Integration

Handheld barcode scanners or mobile apps connected to inventory systems allow employees to count items on the go. The system updates stock levels in real-time as workers scan items during routine tasks, like restocking shelves or fulfilling orders. This eliminates the need for separate counting sessions and keeps data current with minimal effort.

3. RFID Technology for Hands-Free Counting

By enabling hands-free, automated tracking, RFID takes cycle counting to the next level. Tags attached to inventory items communicate with readers around a facility, providing a constant data stream. For example, a warehouse worker passing through a doorway equipped with an RFID reader can unknowingly trigger a count of all tagged items in their cart. This technique is ideal for high-volume environments where speed and precision are paramount.

4. Integration with IoT and Smart Shelves

The Internet of Things (IoT) brings “smart shelves” capabilities to inventory management. Smart shelves with weight sensors or cameras detect when items are added or removed, automatically updating the system. This technique, paired with cycle counting software, ensures real-time accuracy without human intervention—perfect for fast-moving retail settings.

5. Random Sampling with Real-Time Alerts

For businesses with vast inventories, counting every item daily isn’t practical. Random sampling selects a small, statistically significant subset of stock to count each day. When paired with real-time alerts—triggered by software when counts don’t match records—managers can quickly investigate and resolve issues before they escalate.

6. Cloud-Based Inventory Management Systems

Cloud platforms centralize inventory data, making it accessible across multiple locations in real time. Employees can perform cycle counts from any device, and the system syncs updates instantly. This is especially valuable for businesses with distributed warehouses or retail chains, ensuring consistency and visibility at scale.

Best Practices for Success

To maximize the benefits of real-time cycle counting, businesses should keep a few principles in mind:

- Train Staff: Ensure employees understand the tools and processes to avoid errors.

- Start Small: Pilot the system with a single product category or location before scaling up.

- Leverage Analytics: Use data from cycle counts to identify trends, like recurring discrepancies, and address root causes.

- Regularly Calibrate Technology: Maintain scanners, RFID readers, and sensors to ensure accuracy.

Conclusion

As technologies like artificial intelligence and machine learning evolve, they’ll further enhance these techniques. Imagine AI predicting when discrepancies are likely to occur or drones autonomously counting stock in a warehouse. The result? Near-perfect inventory accuracy with minimal effort.

For now, businesses adopting cycle counting with systems like Laceup are already reaping the rewards: tighter control over stock, happier customers, and a healthier bottom line. In an era where efficiency is king, this approach proves that staying ahead doesn’t mean working harder; it means working smarter. If you want to learn more, contact us for a demo or free trial.

I hope this article has been helpful to you. I will continue to post information related to management, distribution practices and trends, and the economy in general. Our channel has a lot of relevant information. Check out this video on Cycle Count To Keep Accurate Inventory.

Sorry, the comment form is closed at this time.