Supply Chain Disruption: Lessons Learned from Recent Crises

The global economy has faced unprecedented challenges over the last few years, with events such as the COVID-19 pandemic, natural disasters, and geopolitical tensions causing significant disruptions to supply chains worldwide. These disruptions have highlighted the vulnerability of global supply networks and their critical role in sustaining economic activities. In this article, I examine the impact of supply chain disruption and the strategies that companies can adopt to mitigate risks and build resilience in their supply chains.

The Impact of Supply Chain Disruption

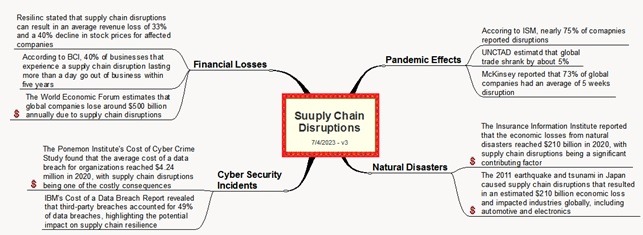

In an interconnected world, supply chain disruptions can have ripple effects across countries and industries. Events in one region can disrupt production and distribution networks globally, affecting businesses that rely on just-in-time inventory management and complex supply chain linkages. Below are the known effects of supply chain disruptions.

Economic Contraction: Disruptions on the supply chain can lead to a contraction in economic activity, as companies face difficulties sourcing raw materials, components, and finished products. The results are production delays, reduced output, and lower consumer spending, contributing to economic downturns.Financial Losses: Supply chain disruptions often translate into profit losses, ranging from inventory write-offs to lost sales and market share. The costs of finding alternative suppliers, expediting shipments, and implementing contingency plans can further strain company finances.

Employment and Labor Market Impacts: Disruptions in supply chains might lead companies to layoffs or reduced working hours, and in extreme cases, companies have to close operations. As a result, workers will suffer income losses that severely affect their life.

Inflation: When disruptions occur, such as transportation bottlenecks, factory closures, or shortages of essential raw materials, the cost of production can increase significantly. These increased costs translate into higher prices for goods and services that affect consumers. Inflation erodes purchasing power, reduces consumer confidence, and can have broader macroeconomic implications, including changes in interest rates, currency values, and economic growth.

Should I prepare my company for eventual supply chain disruption?

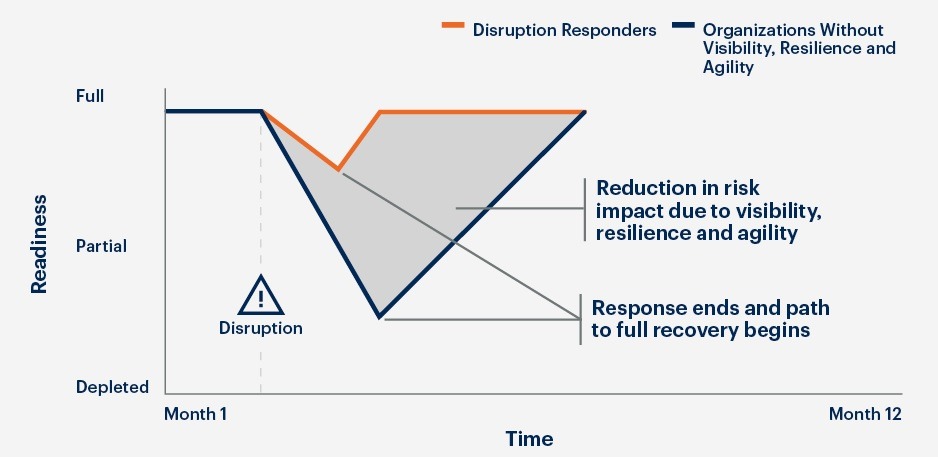

Certainly! Here are a graph that highlights the importance of companies preparing for supply chain disruption:

Strategies to Mitigate Risks and Build Resilience

Assuming that you have accepted the need to prepare, here are some strategies you should consider implementing.

Diversification and Redundancy: Companies can reduce their vulnerability by diversifying their supplier base and geographic sourcing locations. Organizations can distribute risks and establish redundancy in their supply chain by working with multiple suppliers, enabling quicker recovery from disruptions.

Enhanced Visibility and Collaboration: Embracing technologies that provide real-time visibility into supply chain operations is crucial for the early detection of potential disruptions.

Risk Assessment and Contingency Planning: Companies should develop robust contingency plans that address different scenarios, including alternative sourcing options, inventory management strategies, and crisis communication protocols.

Strengthen Supplier Relationships: Building relationships with key suppliers is vital for mutual support during disruptions.

Agile and Flexible Operations: Implementing modular production systems, agile inventory management, and flexible logistics networks allow for fast response to sudden changes in demand and supply patterns.

Reshoring and Regionalization: Recent crises have highlighted the risks associated with over-reliance on distant suppliers. Re-shoring or regionalizing critical supply chain components can reduce the vulnerabilities associated with long-distance sourcing and improve response times during disruptions.

Below is a graph courtesy of Gartner that illustrates the survival chances for companies that are not prepared to face disruptions.

How can a WMS help in mitigating the impact of disruptions?

A Warehouse Management System (WMS) can play a crucial role in mitigating the impact of disruptions in the supply chain. Here are some ways a WMS can help:

Real-time Inventory Visibility: A WMS provides real-time visibility into inventory levels, locations, and movements within the warehouse. This visibility allows companies to have accurate information about stock availability and make informed decisions during disruptions.

Efficient Order Fulfillment: The ability to efficiently process and fulfill orders during disruptions becomes paramount. A WMS optimizes order fulfillment processes by providing features like wave planning, order batching, and optimized picking routes.

Inventory Management and Control: With proper inventory management, companies can quickly identify any discrepancies or shortages resulting from disruptions and take corrective actions to mitigate their impact.

Scalability and Flexibility: Disruptions often lead to changes in order volumes and product demands. A WMS can handle peak periods efficiently, adapt to changes in product assortments, and support dynamic warehouse allocation strategies.

I hope this article has been helpful to you. I will continue to post information related to warehouse management, distribution practices and trends, and the economy in general. If you want to know how Laceup’s solution can help you to successfully prepare for disruption in your supply chain, click the link below to schedule an exploratory meeting.

There is a lot of relevant information on our channel. Check out this video with Tips To Make Your Distribution Company More Profitable.

Sorry, the comment form is closed at this time.