The Essential Features that a Frozen-Grade WMS Must Have

Frozen food distribution is not just a cold-storage version of dry warehousing. It is a completely different operational battlefield. Every minute outside the freezer degrades product quality. Every picking error creates claims, re-delivery costs, and damaged retailer relationships. Every temperature deviation is a compliance risk. A traditional WMS built for ambient products simply cannot manage the operational, regulatory, and financial realities of frozen logistics. This article explains the critical features a Frozen-Grade WMS must have and how each one directly improves efficiency, compliance, and profitability.

Essential Features of a Frozen-Grade WMS Food Distribution

A robust WMS for frozen food distributors goes beyond basic inventory tracking, incorporating features that meet the cold chain’s requirements, such as temperature-sensitive storage and rapid turnover. Here are the key features.

Real-Time Inventory Management: One of the foundational elements of a WMS is its ability to provide real-time visibility into stock levels, locations, and movements. This feature allows warehouse managers to monitor goods as they enter, move through, and exit the facility, reducing the risk of stockouts or overstocking. For frozen foods, this means instantly knowing the status of pallets in different temperature zones, ensuring that items are stored appropriately to prevent thawing or spoilage.

Temperature Monitoring and Control: Frozen food requires strict adherence to cold chain protocols, and a WMS integrates with sensors and IoT devices for automated temperature monitoring. Alerts can be triggered if temperatures deviate from set thresholds (e.g., below -18°C for deep-frozen items), allowing immediate corrective action. This feature not only preserves product integrity but also supports compliance with standards like HACCP (Hazard Analysis and Critical Control Points) and FDA regulations.

Traceability and Compliance: Full traceability is crucial in the food industry for recalls and audits. A WMS offers lot and batch tracking, recording every step from receipt to shipment, including supplier details, entry dates, and handling history. For frozen distributors, this ensures quick identification of affected products in case of contamination or quality issues, minimizing financial and reputational damage. Additionally, it manages expiry dates using FIFO (First In, First Out) or FEFO (First Expired, First Out) to prioritize older stock.

Order Management and Fulfillment: Efficient order processing is vital for meeting customer demands. WMS systems enable intelligent order waving, grouping orders by criteria such as shipping timelines, product types, or storage needs (e.g., refrigerated vs. frozen). Features like voice-directed picking or barcode scanning speed up fulfillment while reducing errors, ensuring that orders are picked accurately and packed in insulated containers to maintain the cold chain.

Integration Capabilities: A modern WMS seamlessly integrates with other systems, such as ERP (Enterprise Resource Planning), TMS (Transportation Management Systems), and e-commerce platforms. This connectivity allows for automated data flow, from purchase orders to delivery confirmations, creating a unified ecosystem that supports end-to-end visibility in the supply chain.

Reporting and Analytics: Advanced analytics provide insights into warehouse performance, such as throughput rates, labor efficiency, and inventory turnover. For frozen food operations, customizable reports can highlight trends in spoilage rates or energy usage in cold storage, enabling data-driven decisions to refine processes.

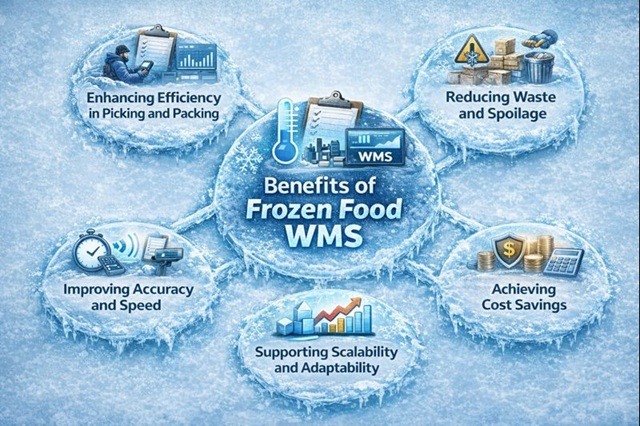

How a Frozen-Grade WMS Food Distribution Optimizes Operations

Beyond its features, a well-implemented WMS transforms warehouse operations by automating routine tasks, reducing human error, and adapting to dynamic demands. Here’s how it drives optimization.

Enhancing Efficiency in Picking and Packing: By directing workers by zone, product type, or urgency, the WMS minimizes travel time within the warehouse, which is critical in large cold storage facilities where prolonged exposure can affect worker safety and energy costs. Intelligent task management balances workloads, leading to faster order fulfillment and higher throughput. For instance, the system can prioritize high-velocity items near picking areas, reducing handling time for popular frozen products.

Reducing Waste and Spoilage: Through real-time monitoring and automated alerts, a WMS prevents temperature excursions that could lead to product loss. Expiry tracking ensures perishable items are shipped before they degrade, reducing waste. In practice, this optimizes stock rotation, potentially reducing spoilage by up to 20-30% in frozen food environments.

Improving Accuracy and Speed: Automation in inventory tracking eliminates manual counts, providing precise data that supports better forecasting and replenishment. This accuracy extends to compliance, where traceability features enable rapid recalls, often completing what used to take days in hours. Overall, operations become more agile, allowing distributors to handle peak seasons or unexpected surges without compromising quality.

Achieving Cost Savings: A WMS streamlines processes to lower labor costs by optimizing routes and reducing overtime. It also minimizes energy use by controlling door openings and temperature zones, and strategic warehouse layouts reduce transit times in the cold chain. Long-term, these efficiencies can lead to significant savings, with some systems reporting up to 15% reductions in operational overhead.

Supporting Scalability and Adaptability: As businesses grow, a scalable WMS integrates new technologies like AI for predictive analytics or robotics for automated storage. This future-proofing ensures the system evolves with the distributor, handling increased volumes or expanded product lines without major disruptions.

Conclusion

For frozen food distributors, investing in a specialized Frozen-Grade WMS is not just about technology; it’s about safeguarding product quality, ensuring regulatory compliance, and driving profitability through optimized operations. By leveraging real-time data, automation, and intelligent workflows, these systems turn complex challenges into competitive advantages. Distributors should evaluate WMS solutions based on their specific needs, such as ease of integration and cold-chain focus, to maximize returns. In an industry where every degree and minute counts, a robust WMS is the key to staying ahead.

At LaceUp Solutions, we explore how technology transforms distribution, from warehouse management and route optimization to digital sales enablement. Subscribe to the LaceUp Blog for weekly insights on wholesale growth, innovation, and the future of logistics. For more information, please get in touch with us to learn about our solutions.

I hope this article on Frozen-Grade WMS have been helpful. I will continue to post information related to management, distribution practices and trends, and the economy in general. Our channel has a lot of relevant information. Check out this video on Frozen Food Distributors.

Sorry, the comment form is closed at this time.