Warehouse Labor Shortages: How WMS help Addressing Workforce Challenges

The labor shortage is a harsh reality impacting businesses across industries. Warehouses, in particular, are feeling the pinch, struggling to fill open positions while facing an ever-growing demand for efficient order fulfillment. In this article, I describe the reasons for warehouse labor shortages, their impact on warehouse operations, and how to overcome them.

Warehouse Labor Shortages

The American Staffing Association forecasts warehouse and transportation job openings will hit 1.7 million in 2024, with a projected increase up to 2.1 million jobs by 2030, with high recruiting time and turnover. The shortage stems from multiple factors, the most relevant being:

Demographic Shifts: Aging populations are leading to a shrinking workforce.

Skills Mismatch: Rapid technological advancements require workers with specialized skills, leading to a gap between available talent and required expertise.

Economic Shifts: Changes in consumer behavior, globalization, and economic downturns can impact job availability and workforce participation.

Pandemic impact: COVID-19 disrupted traditional work models and shifted priorities, leading to workers leaving demanding sectors like warehousing.

Changing expectations: Millennial and Gen Z workers prioritize work-life balance and meaningful jobs, often finding traditional warehouse roles lacking.

Impact of Warehouse Labor Shortages in Warehouse Operations

Warehouse labor shortages have specific consequences on warehouse operations. These are some figures illustrating this impact.

Slowed order fulfillment: With fewer workers, processing orders takes longer, leading to customer dissatisfaction and lost revenue. Fulfillment times are increasing by 60% due to labor shortages (Logistic Management).

Increased operational costs: Overtime pay and bonuses to incentivize existing staff contribute to higher expenses, and warehousing wages have increased by 10% driven by competition for workers. (According to JLL)

Operation disruption: 37% of companies report supply chain disruptions due to labor shortages. (Source: Deloitte).

WMS and Automation in reducing Warehouse Labor Shortages

WMS are software solutions designed to optimize warehouse operations, and their integration with automation tools offers a powerful solution to the labor shortage.

Effects of a WMS implementation in labor shortage

Automated tasks: Repetitive tasks like picking, packing, and sorting can be handled by robots, freeing up human workers for more strategic roles.

Inventory Optimization: WMS utilizes real-time data to optimize inventory levels, ensuring that stock levels are balanced to meet demand without excess or shortage. Automated inventory tracking and replenishment systems minimize the need for manual stock checks and restocking, reducing labor requirements.

Order Fulfillment Efficiency: WMS streamlines order processing workflows, from order receipt to shipment, by orchestrating the movement of goods and tasks within the warehouse. Automation technologies such as robotic picking systems and conveyor systems integrated with WMS can significantly accelerate order fulfillment, even with a reduced workforce.

Dynamic Resource Allocation: WMS enables dynamic resource allocation based on demand fluctuations and operational priorities. With automation, WMS can adjust workforce deployment and task assignments in real-time, maximizing efficiency and minimizing labor bottlenecks.

Data-driven decision making: Insights from the WMS help identify bottlenecks and optimize workflows, further increasing productivity.

Overcoming Implementation Challenges

While the benefits of leveraging WMS for automation are substantial, organizations may face challenges during implementation. These challenges include upfront costs, integration complexities, workforce reskilling, and resistance to change. However, with proper planning, strategic investment, and effective change management, organizations can overcome these challenges and realize long-term benefits in terms of productivity, efficiency, and competitiveness.

Beyond Efficiency: The Human Factor

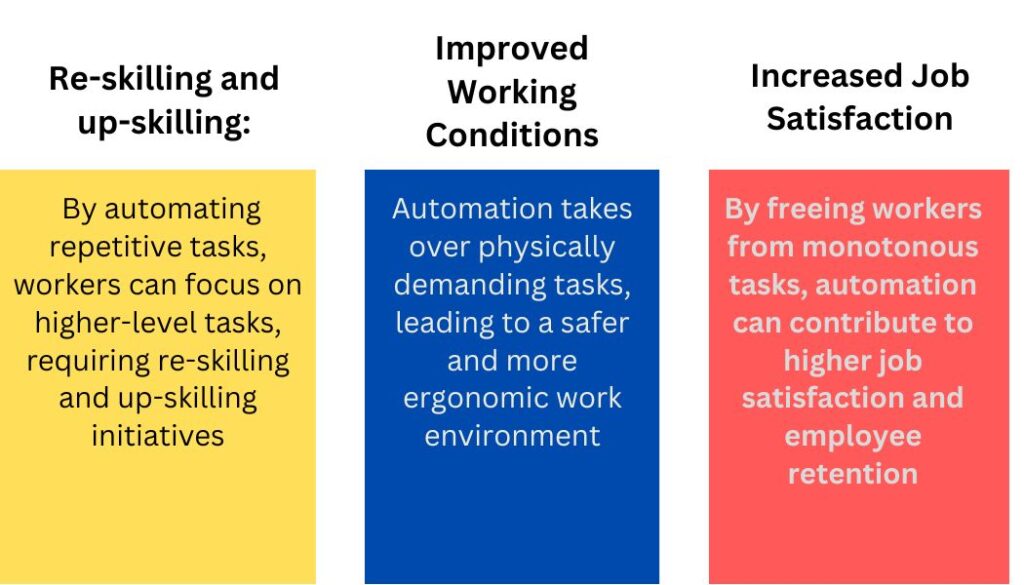

While automation addresses labor shortages, it’s crucial to remember the human element. Here’s how WMS can contribute to a positive impact:

I hope this article about warehouse labor shortage has been helpful to you. I will continue to post information related to warehouse management, distribution practices and trends, and the economy in general. If you are interested in learning more, click the link, and we will call you.

There is a lot of relevant information on our channel. Check this video on How To REDUCE Turnover in YOUR Warehouse.

Sorry, the comment form is closed at this time.