Warehouse Management System implementation – Why does it fail?

In previous articles, I have addressed why you need to implement a Warehouse Management System, features you should look for, and how WMS compares to Inventory Management. However, even though, in most of the cases, Warehouse Management System implementation is a success, in many instances it fails at fulfilling the company’s expectations. In today’s article, I will explain the main reasons why the implementation of a WMS may fail.

Why a Warehouse Management System implementation might fail?

There are many reasons why a WMS might not be successful: lack of commitment, budget problems, unrealistic expectations, wrong people involved, and the list goes on. But in my experience, they can be grouped into two categories: Inaccurate data and Deficient Planning. Let’s go ever them.

Reason 1: Inaccurate data to be loaded in the WMS

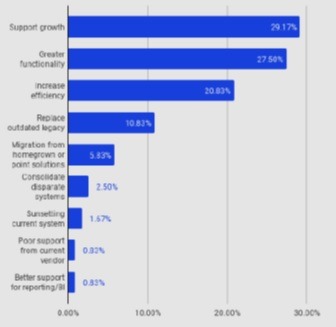

A study made by Software Path indicates that 77.43% of the companies decide to implement a WMS to cope with growth, process improvement, and increase efficiency. It also shows that 100% of companies going to a new warehouse management system have already a system in place. It might be a basic or older WMS, a module of their ERP, or a system with poor support.

The implementation of a WMS involves the loading of two key data from the existing system: product information and warehouse layout. How do they affect the implementation?

Inaccurate product information

One of the main reasons why I have seen warehouse management system implementation projects fail is that the product information in the old system is not accurate and sometimes it is redundant. There is a saying in the software industry that goes “if you input garbage in a perfect software, you will get perfect output garbage”. The only way to avoid this is by being aware of the problem and forming a team to clean up, debug and organize the information before transferring it to the new system.

Inaccurate product location

If your operation requires pinpointing the exact location of products in the warehouse, then you need to have a comprehensive layout and accurate information regarding where the products are located, before inputting that information in the WMS.

It is important to bear in mind that the implementation of a WMS has to be done concurrently with the day-to-day operations. One of the main headaches I´ve run into, especially in companies that are migrating from a general location warehouse to a detailed location one, is how to ensure that the products are located in the right bin or space by the time the information is loaded into the new WMS and with minimum disruption of the operation. This is a hard and resource-consuming process since it involves:

- Labeling all spaces and bins in the warehouse

- Mapping the warehouse layout into the system

- Relocating all products into their right location whilst continuing picking and delivering

Reason 2: Deficient Planning

Many owners fail to see that the implementation phase of the project requires a “planning” stage and setup implementation goals based on the needs of the company rather than a reasoned analysis. A good planning process must define the following issues.

- Ownership and realistic goals

- Personnel to be allocated to the implementation team

- List of activities

- Base timeline

- Base budget line

Ownership and unrealistic goals

For a successful warehouse Management System Implementation, the top management has to be committed to the project and provide the top-level vision that will define the goals and resources for the implementation. Specifically:

- Goal prioritization: When a company decides to implement a WMS is because there are several situations they want to improve. Trying to achieve all of them with the initial implementation is not realistic. It is the task of the project owner to tell the most critical goals to be achieved from the less critical ones and then set up stages of implementation with their corresponding goals.

- Manage cultural change: t A Warehouse Management System implementation implies changes in the processes and the culture of the company. Most implementations do not pay proper attention and resources to this. Cultural Change involves training at all levels but it also means awareness of business drivers for change, knowledge of how to support that change, the willingness of the end-users to perform their jobs differently, impact on the organization if the implementation fails, and how to manage the expected resistance that will occur at all levels.

Resource allocation

For successful implementation of a WMS, you need to involve the people that will manage and use the system and make sure that they understand their role and commitment. Typically you need a subset of the following roles.

- Project manager: The person leading the implementation team and responsible for its success.

- Warehouse leader: someone from the warehouse management team that will provide the perspective of the actual limitations and specifics of the operation.

- Database administrator: This person will be responsible for managing the existing data and assisting with the data migration process.

- IT engineer: responsible for the technical aspects of the implementation like platform, integration with existing systems, and outside applications like EDI.

- WMS expert/trainer: the person who will be using your new WMS the most should be part of the implementation team and will be responsible to train new hires on your WMS.

I have seen many cases where the implementation fails because the resource allocation was loose and training was not considered in the implementation. This is one of the reasons why many warehouse system providers reserve for themselves the implementation. This way they ensure that the right people from their rank will devote the required time to grant success. The drawback is that the implementation costs are higher.

List of activities and Base Timeline

The deadline to start using the system has to be the result of a detailed list of activities tied to the personnel assigned to do them, rather than an arbitrary date set up by the owner or the CEO. For example, suppose that debugging the product data takes 1 week of work of 1 person. If you assign that task to a data entry employee that can do that in their spare time, then the “real” time for that activity could be 2, 3, or 4 weeks. This is the type of considerations to be taken into account in order to set up a realistic implementation time. The key is to have a complete list of steps required to implement the system, with execution time related to the complexity of the activity and the time availability of the person that will do it.

The study mentioned above shows that, on average, companies spend 15 weeks selecting and planning the Warehouse Management System implementation. Take this into consideration and do not dismiss the importance of this process.

Budgeting

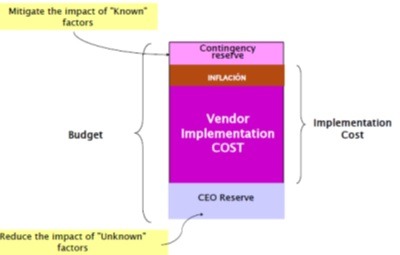

In many cases, the budget allocated runs out before the implementation is complete. The main reason why this happens is a deficient planning process: the complexity of tasks was underestimated; resource availability was lower than calculated; contingencies in the daily operation; additional activities that were not contemplated, etc. Now, delays and contingencies that affect timeline and budget are very normal in any implementation. The best way to prevent that these contingencies result in fail by a budget implementation is by including a “contingency reserve” and/or “CEO Reserve” fund into the budget. So, the Budget vs the expected cost will look like this.

Conclusions

Nobody wants a failed warehouse management system implementation, but unfortunately, they do occur. A careful and realistic planning process and detailed attention to the accuracy of the information to be transferred to the system will lead to a successful implementation. I hope this article has been helpful to you. I will continue to publish information related to Warehouse Management, distribution practices, and economy issues. If you are interested in this article or want to learn more about LaceUp Solutions, register to keep you updated on future articles.

Sorry, the comment form is closed at this time.